Flexible positioning device for automobile glass in die

A flexible positioning, automotive glass technology, applied in the coating and other directions, can solve the problems of glass shifting, unsightly, inconvenient operation, etc., and achieve the effects of high production efficiency, good stability and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

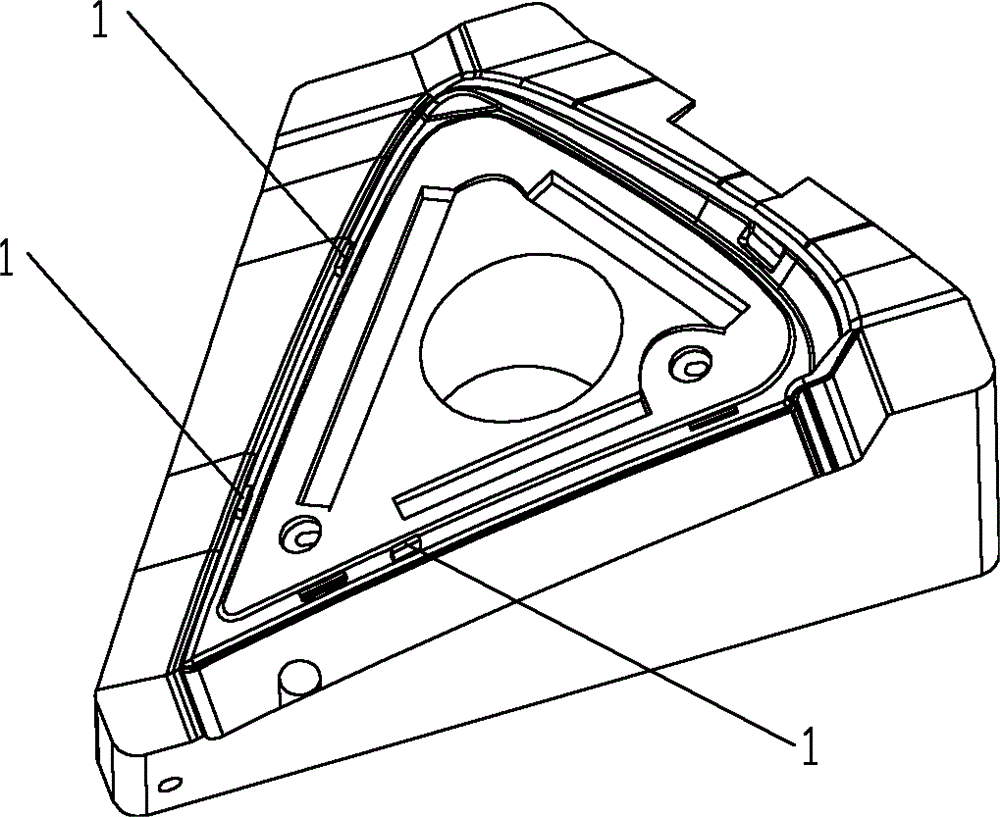

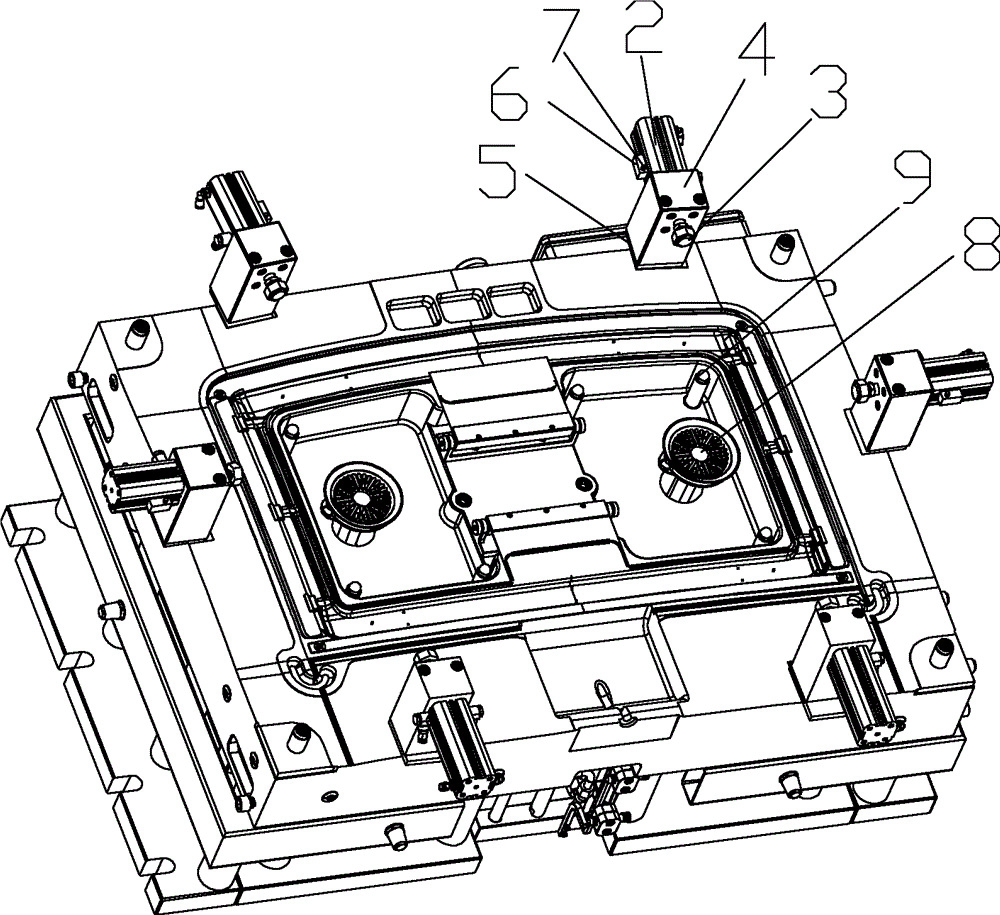

[0017] Such as figure 2 As shown, a flexible positioning device for automotive glass in a mould, the device includes a positioning unit, an induction unit, and an adsorption unit. The positioning unit is composed of a linear cylinder 2, a positioning head 3, a cylinder seat 4, and a heat shield 5. The positioning head 3 is installed on the linear cylinder 2, the disc spring is provided in the positioning head, the linear cylinder 2 is installed on the cylinder block 4, the cylinder block 4 is arranged on the mold, and there is a spacer between the mold and the mold. Hot plate 5; described induction unit is made up of proximity switch 6, and the proximity switch connector 7 that is arranged in the proximity switch; described adsorption unit is made up of suction cup 8 and support bar 9, and suction cup 8 is provided with 2, supports There are 4 rods 9 (the number of suction cups and support rods can be set according to the size of the glass, 2 to 4 or more suction cups and 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com