Water-channel water-returning littoral combat ship

A coastal and waterway technology, applied in the direction of ships, ship propulsion, ship parts, etc., to achieve the effect of good application value, small swing and inclination angle, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

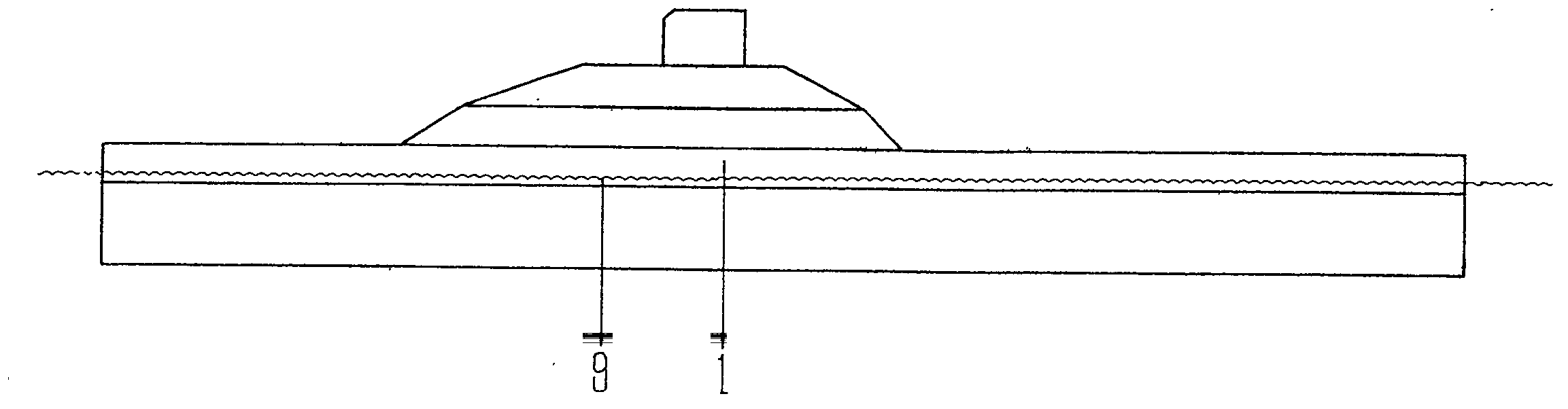

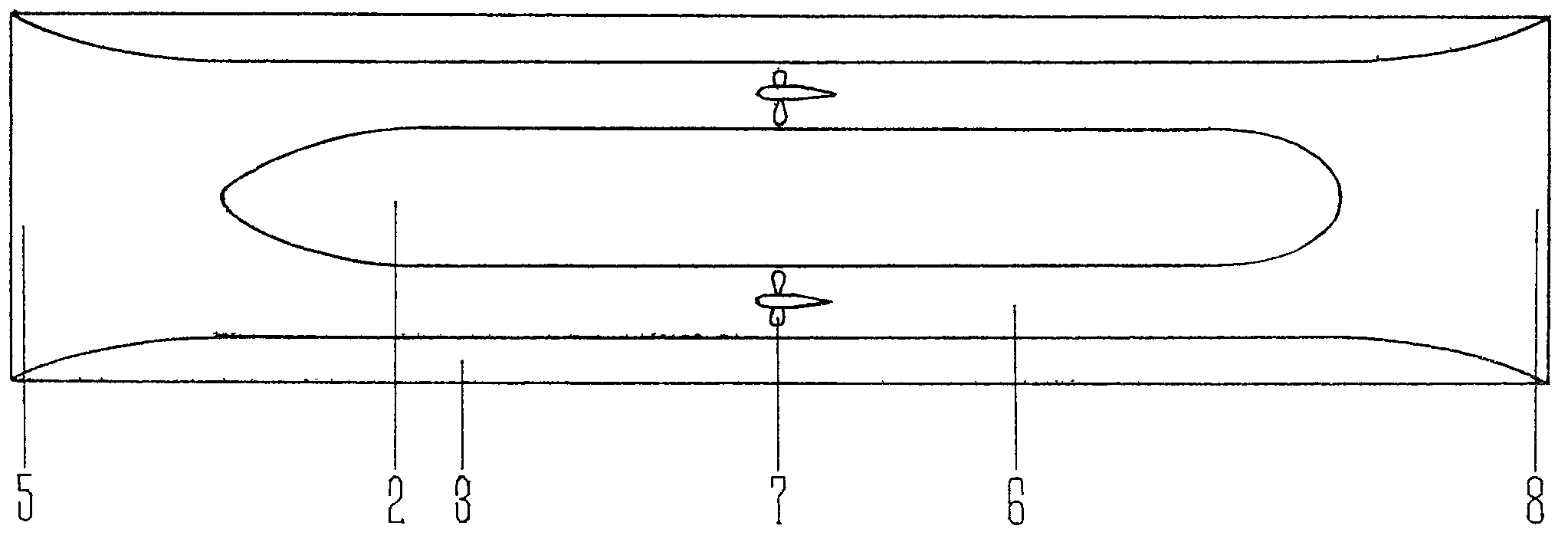

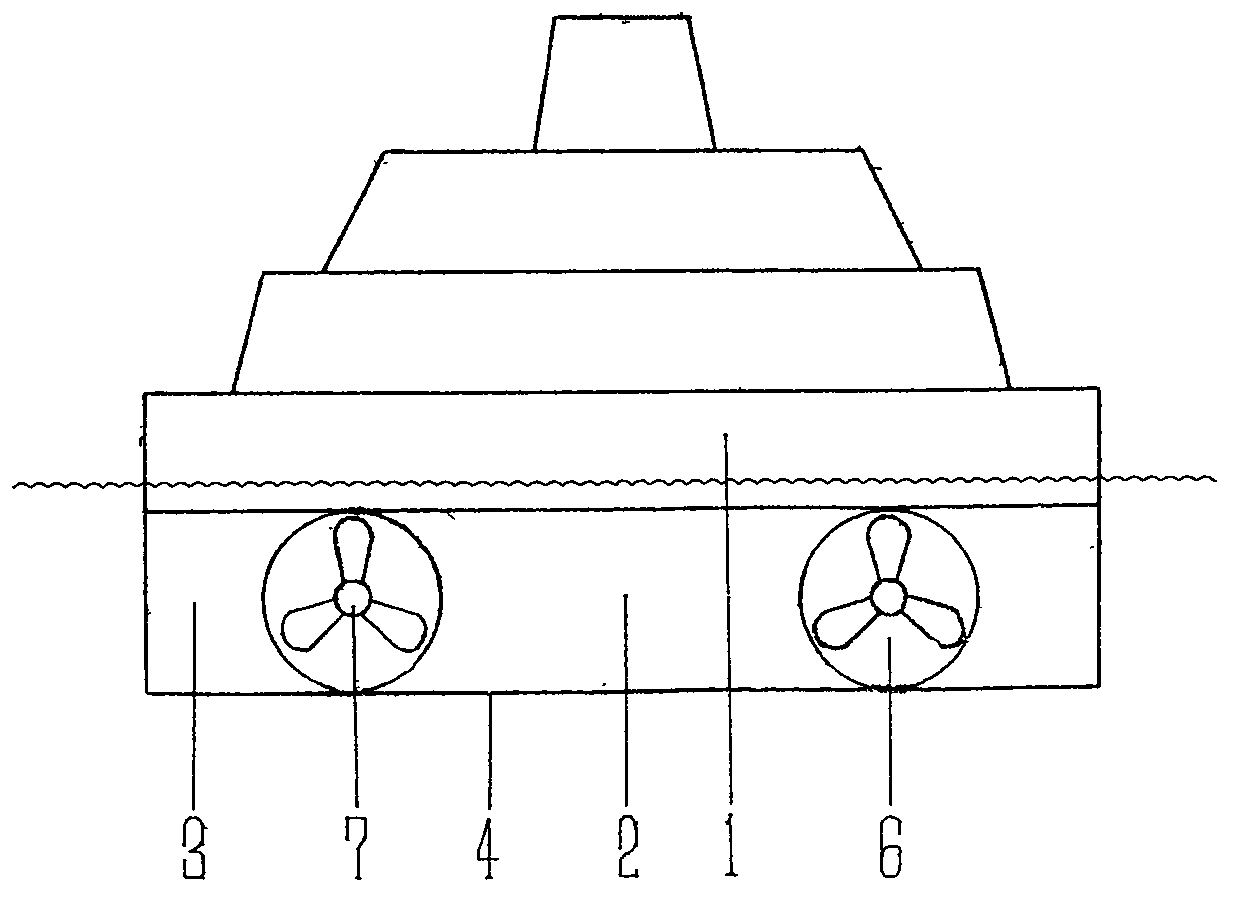

[0018] As shown in the figure: the waterway waterfront combat ship is composed of the lower part of the hull 1, the bottom plate 4 and the side cabins 3 arranged in parallel to form a long rectangular cubic bottom tank. The cabins 3 on both sides are hollow structures with flat outside and convex inside and two ends with acute angles. The middle cabin 2 is a streamlined hollow body whose length is shorter than the bottom plate 4 . The gap between the middle cabin 2 and the side cabin 3 is a waterway 6 . A propeller 7 is arranged in the middle part of the water passage 6, and the two ends of the long rectangular cuboid bilge are respectively a rectangular water inlet 5 and a water outlet 8. The bottom of the water inlet 5 and the water outlet 8 is the bottom plate 4, the sides are the acute-angled tip of the tanks 3 on both sides, and the top is the bottom of the hull 1. The top of the water inlet 5 and the water outlet 8 is lower than the water surface 9 .

[0019] The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com