Cracking furnace for tire

A technology for pyrolysis furnaces and tires, which is applied in coke ovens, special forms of dry distillation, and preparation of liquid hydrocarbon mixtures. It can solve the problems of many impurities in the gas, low product quality, and insufficient cracking, and achieve good product quality and environmental pollution. Small, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

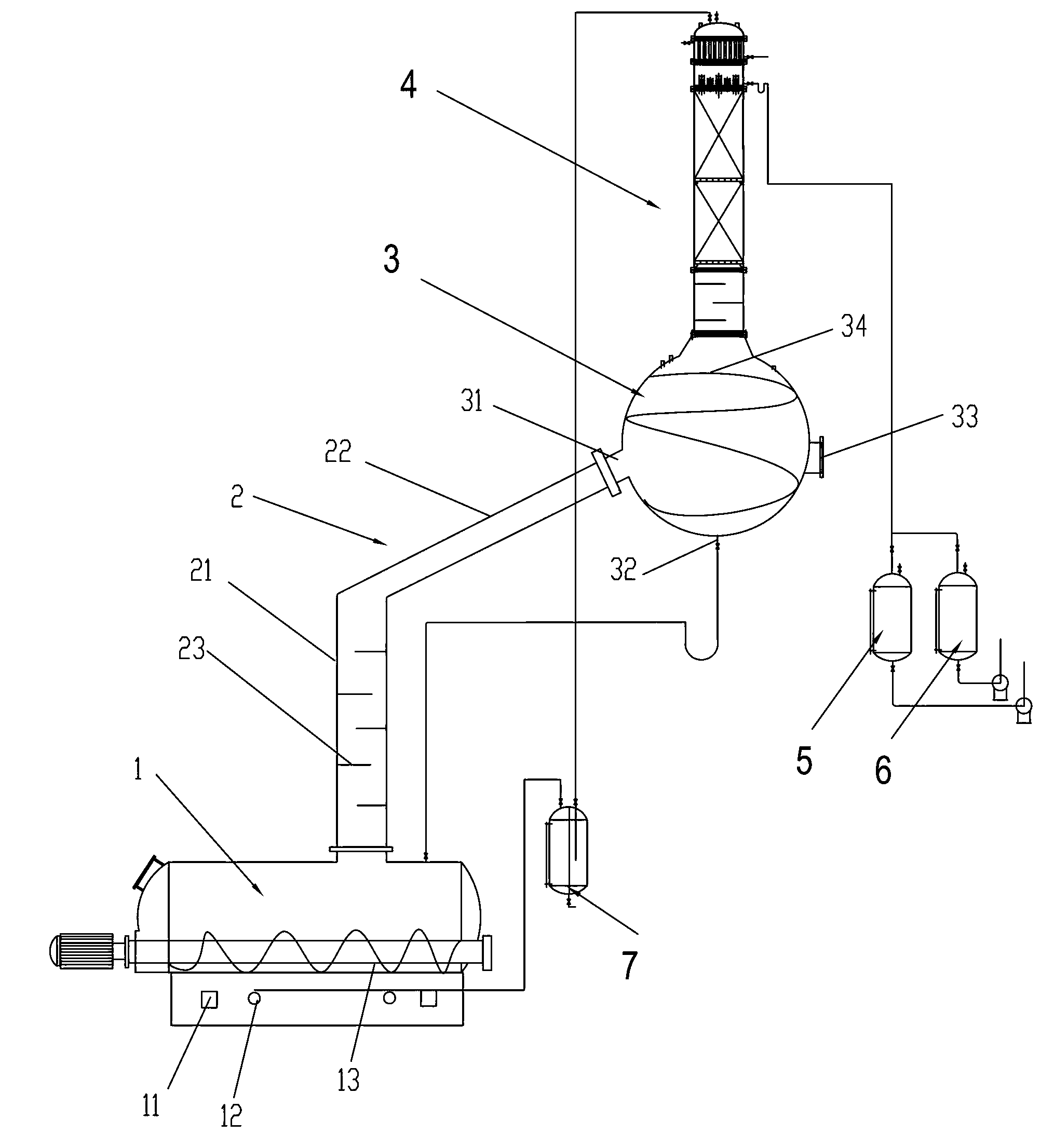

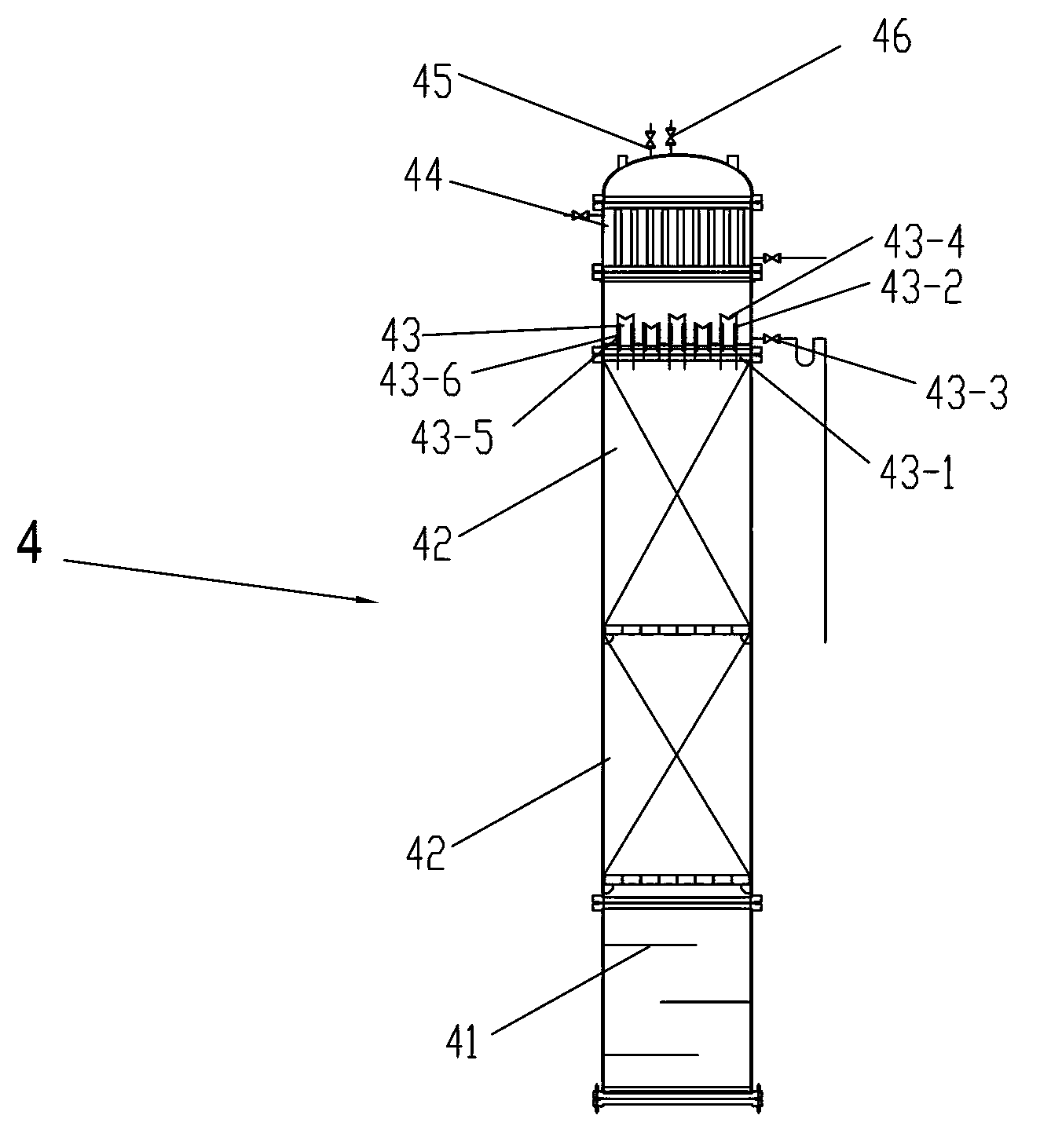

[0040] For specific embodiments of the present invention, refer to figure 1 , a tire cracking furnace, mainly by cracking furnace main body 1, connecting pipe 2, spherical tank 3 and separation tower 4 and other components.

[0041] The main body 1 of the cracking furnace is a built-in spiral scraper type (it is the prior art, other cracking furnaces in the prior art can also be used), which includes a fixed outer cylinder and a rotatable built-in spiral scraper 13 . A fuel inlet 11 and a gas inlet 12 are provided at the bottom thereof. This cracking furnace is the prior art, and this part is not the focus of the present invention, so it will not be described in detail.

[0042] The top of the pyrolysis furnace main body 1 is connected with a connecting pipe 2 , and the connecting pipe includes a vertical section 21 and an inclined section 22 , wherein a plurality of baffles 23 are alternately distributed on the vertical section 21 . The number of the baffles can be set as r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com