Cyclone airlift fermentation tank

A fermenter and gas flow technology, which is applied in the field of swirling air-lift fermenter, can solve the problems of poor energy saving effect of non-stirred fermenter, inability to apply fermenter, and influence on growth and metabolism, and achieve good gas-liquid mixing effect and gas-liquid mixing Low consumption, high efficiency and high fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

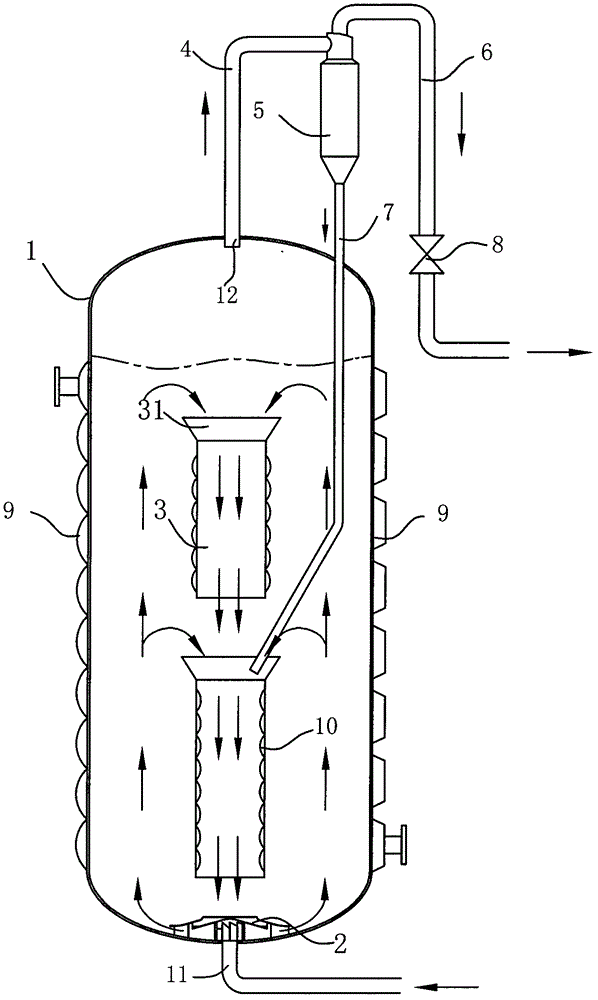

[0020] like figure 1 As shown, a swirling airlift fermenter comprises a cylindrical vertical tank body 1, an air intake device, an exhaust device, a flow guiding device and a cooling device, and the tank body 1 is provided with an air intake pipe 11, Exhaust pipe 4 and various necessary pipeline interfaces, the air intake pipe 11 is located at the center of the bottom of the tank body 1 or near the center of the bottom of the tank body 1, and is connected with the air intake device, and the exhaust pipe 4 is provided with The central position on the top of the tank body 1 is connected with the exhaust device.

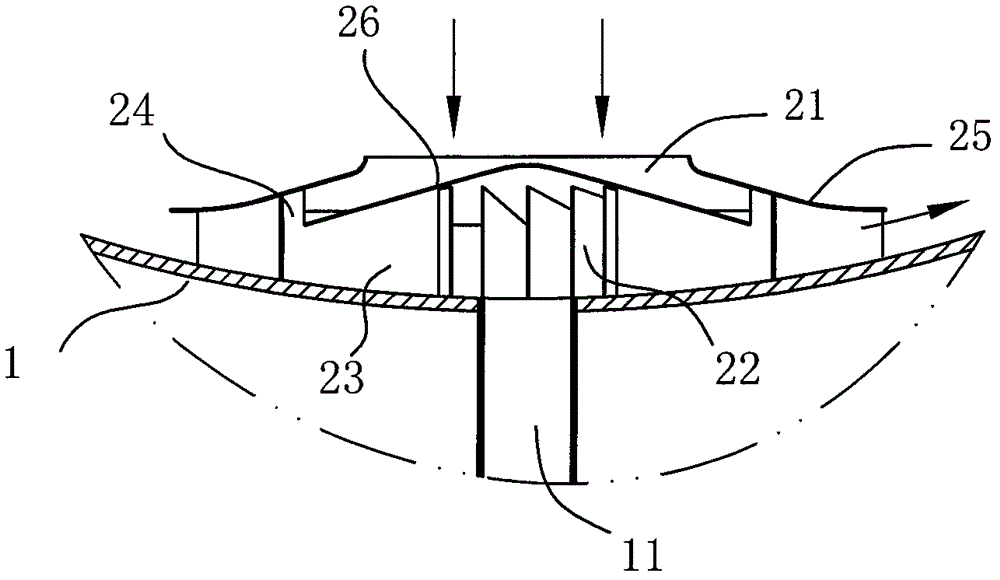

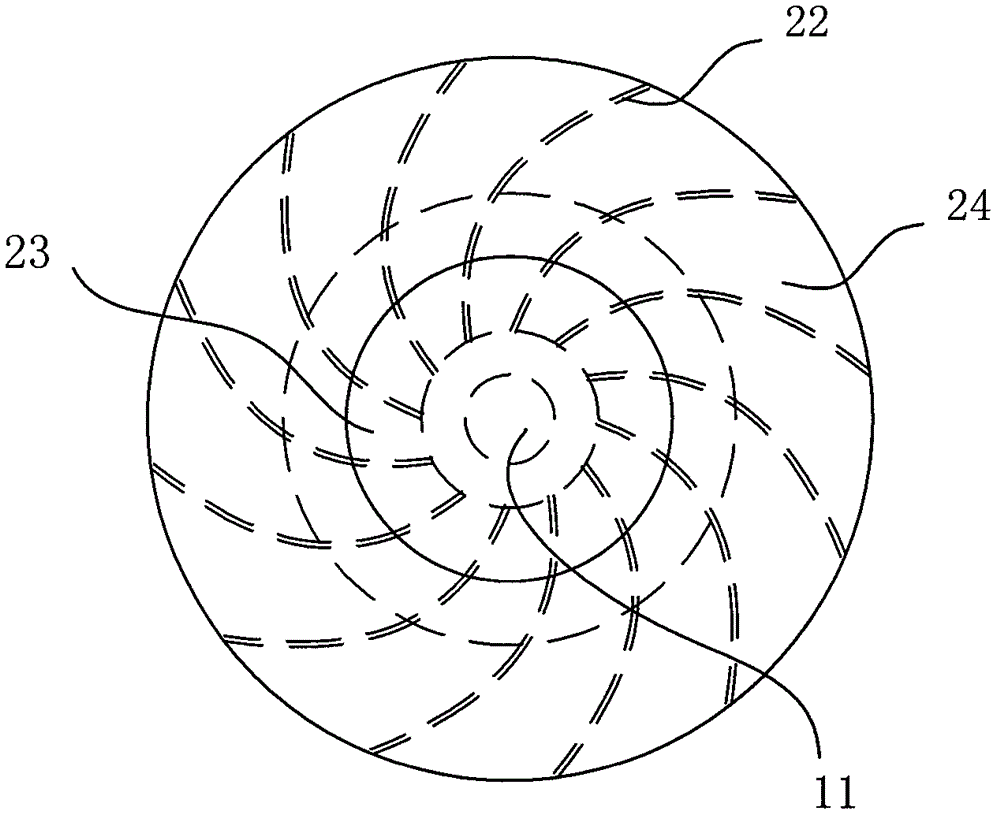

[0021] like Figure 2a , 2b As shown, the air intake device is a swirl mixer 2, which is arranged at the bottom of the tank body 1, installed close to the lower head of the tank body 1 and connected to the air inlet pipe 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com