Rapid metal plate molding sample piece and manufacturing method thereof

A kind of sheet metal parts, rapid technology, applied in the field of metal parts processing, can solve the problems of easy deformation of sheet metal rapid prototyping samples, high processing equipment requirements, affecting product performance, etc., to improve product quality and product qualification rate , save material and time, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

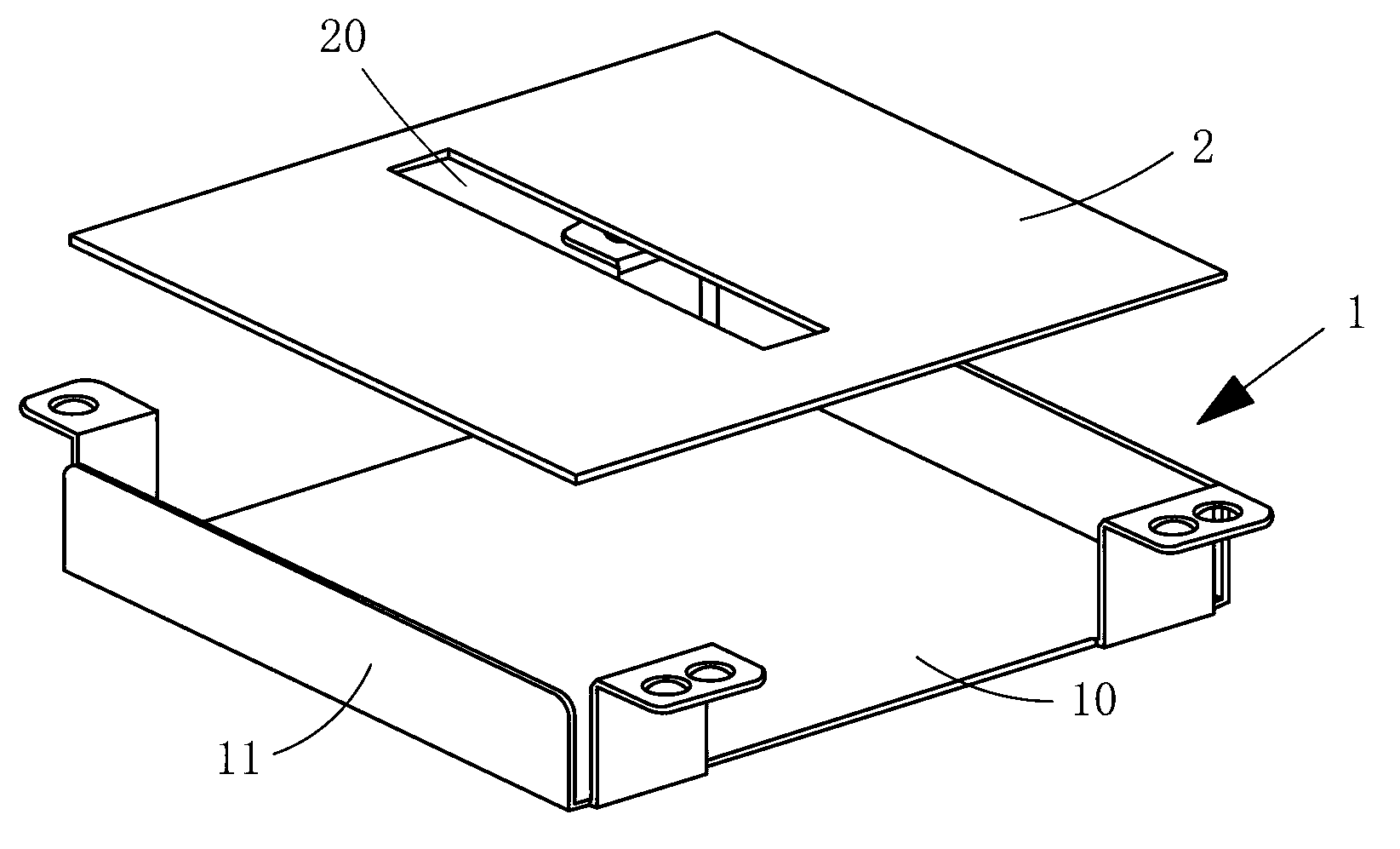

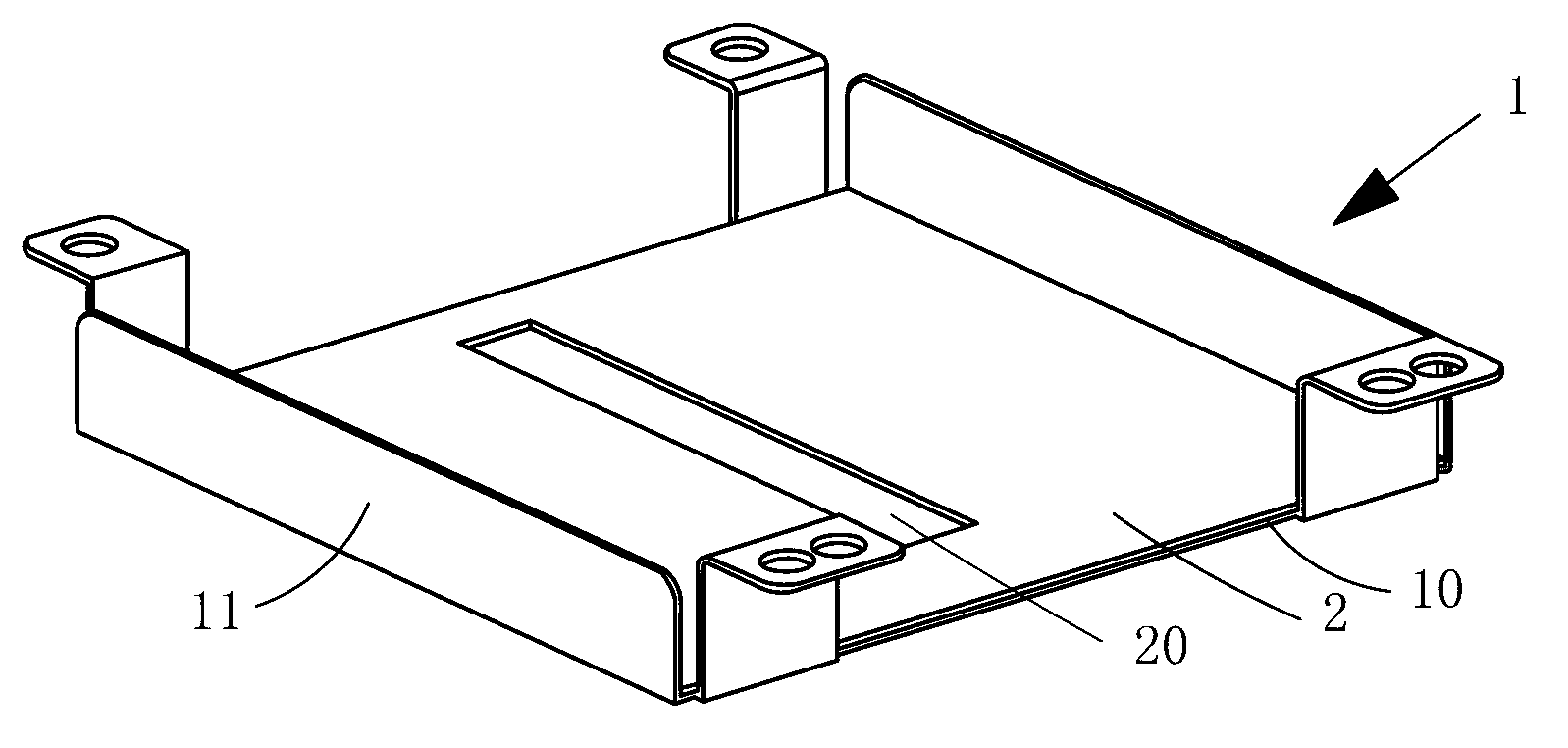

[0030] Such as figure 1 and figure 2 Commonly shown, a kind of sheet metal rapid prototyping sample, comprises sheet metal body 1, and the base plate 10 of sheet metal body 1 is provided with the metal plate 2 that is combined with base plate 10, and the size and shape of metal plate 2 and The bottom plate 10 is suitable, the metal plate 2 is provided with an opening 20, the shape of the opening 20 is consistent with the shape of the required groove, the size of the opening 20 is consistent with the size of the required groove, and the metal plate 2 The thickness is consistent with the depth of the required groove. Owing to adopting the structure that the metal plate 2 with the same opening 20 of the required groove size and shape is combined with the base plate 10 of the sheet metal body 1, the opening 20 on the metal plate 2 and the base plate 10 just constitute the required groove. Compared with the sheet metal rapid prototyping sample in the prior art, the sheet metal ...

Embodiment 2

[0038] Such as image 3 As shown, a sheet metal rapid prototyping sample, its structure is basically the same as that of Embodiment 1, the difference is that: the metal plate 2 with the opening 20 is integrated with the side wall 11 of the sheet metal body 1, and the metal plate 2 is adapted in size and shape to the side wall 11. In the manufacturing steps of the above sheet metal rapid prototyping sample, the perforated metal plate 2 is pasted on the inner side of the side wall 11 to obtain a sheet metal rapid prototyping sample with grooves on the side wall 11 .

Embodiment 3

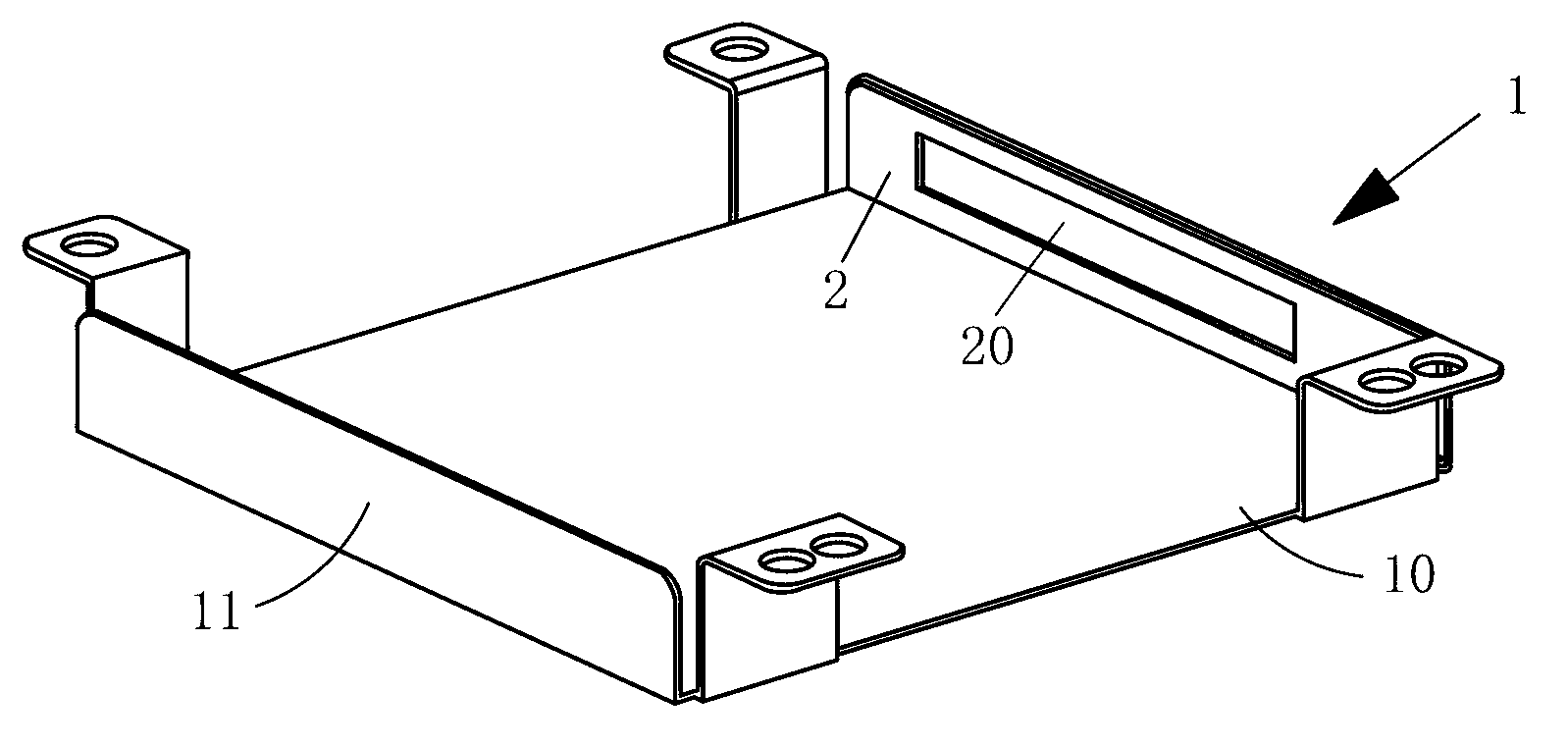

[0040] Such as Figure 4 and Figure 5Commonly shown, a sheet metal rapid prototyping sample, including a sheet metal body 1, the base plate 10 of the sheet metal body 1 is provided with a metal plate 2 integrated with the base plate 10, the size of the metal plate 2 is smaller than the base plate 10 The size, and the thickness of the metal plate 2 is consistent with the height of the required protrusion, and the shape and size of the metal plate 2 are consistent with the shape and size of the required protrusion. Since the metal plate 2 with the same shape and size as the required protrusion is integrated with the base plate 10, the metal plate 2 forms the required protrusion on the base plate 10. Compared with the sheet metal rapid prototyping sample in the prior art, the sheet metal rapid prototyping sample of this structure has the following advantages: one, because the link of making a simple and easy stretching die is omitted, so the processing technology is simplified,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com