Method used for improving measuring accuracy of point-diffraction interferometer

A point-diffraction interferometer and a technology for testing accuracy, which is applied in the field of point-diffraction interferometer testing, can solve the problems of point-diffraction interferometer test accuracy drop, camera can not be saturated, edge image analog-to-digital conversion digits drop, etc., to achieve easy processing and manufacturing , improve the test accuracy, the effect of simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0016] A method for improving the test accuracy of a point diffraction interferometer, the method comprising the steps of:

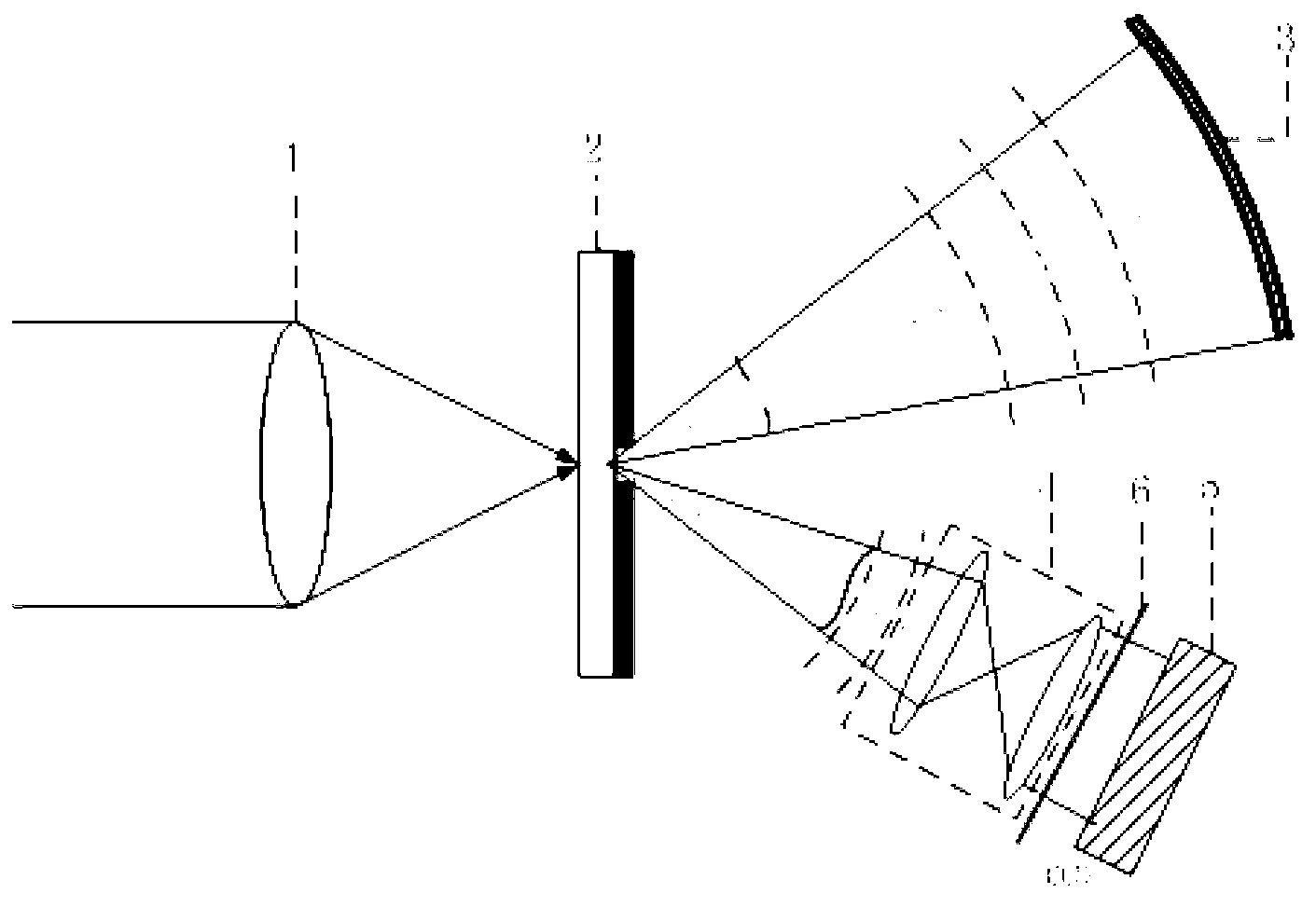

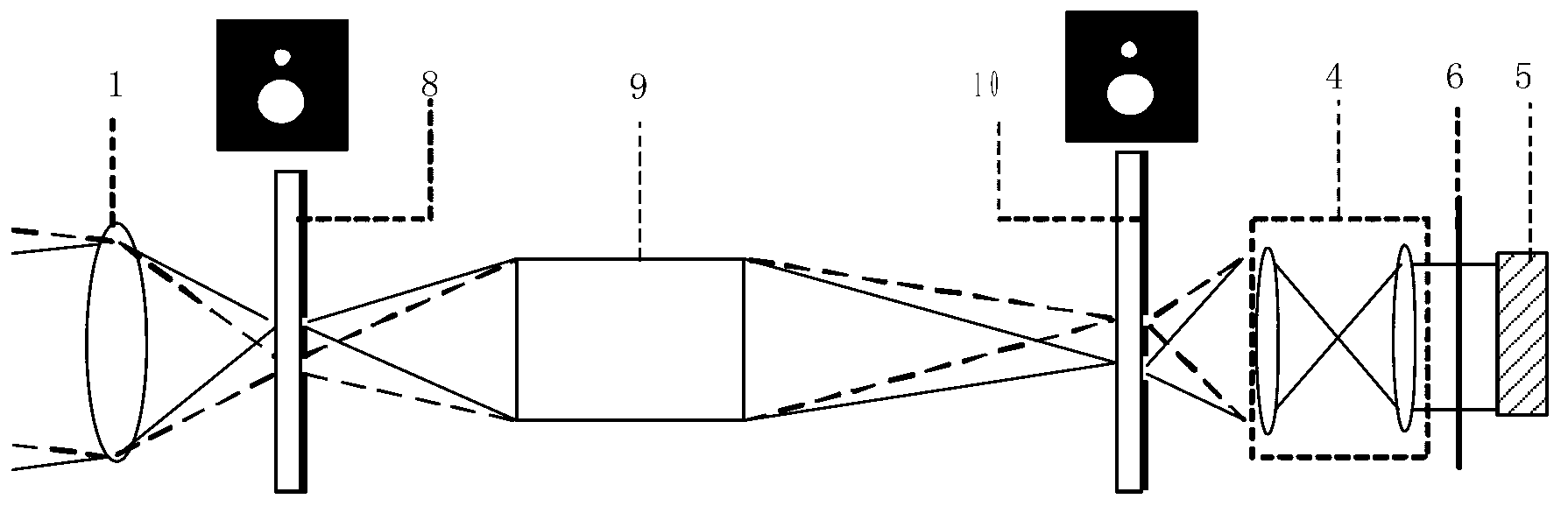

[0017] Step 1: Place the converging lens and the small orifice plate on the same optical axis, the parallel light source is converged by the converging lens, and exits through the small orifice plate, part of the light forms the test light, and the other part of the light is used as the reference light; the test light and reference light are imaged by the camera The common light path at the exit pupil of the lens;

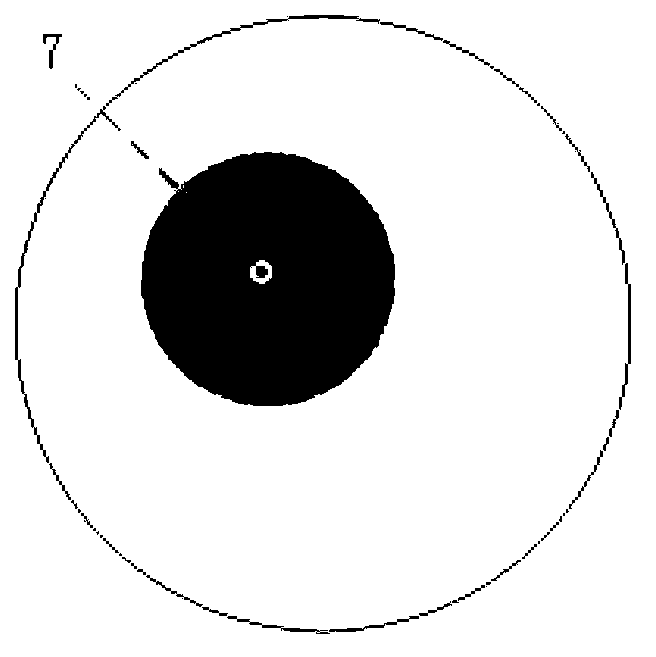

[0018] Step 2: Record the maximum value of the exit pupil light intensity at the exit pupil of the imaging lens as A, and place an attenuation sheet centered at point A, with gradually increasing transmittance along the radial direction, to adjust the exit pupil beam of the imaging lens The intensity distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com