Built-in electromagnetic heating roll

An electromagnetic heating roller and built-in technology, which is applied to the field of printing and dyeing rollers, can solve the problems of uneven surface temperature of the applicator roller, complex mechanical structure and high equipment cost, and achieve the effects of convenient construction, uniform temperature and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

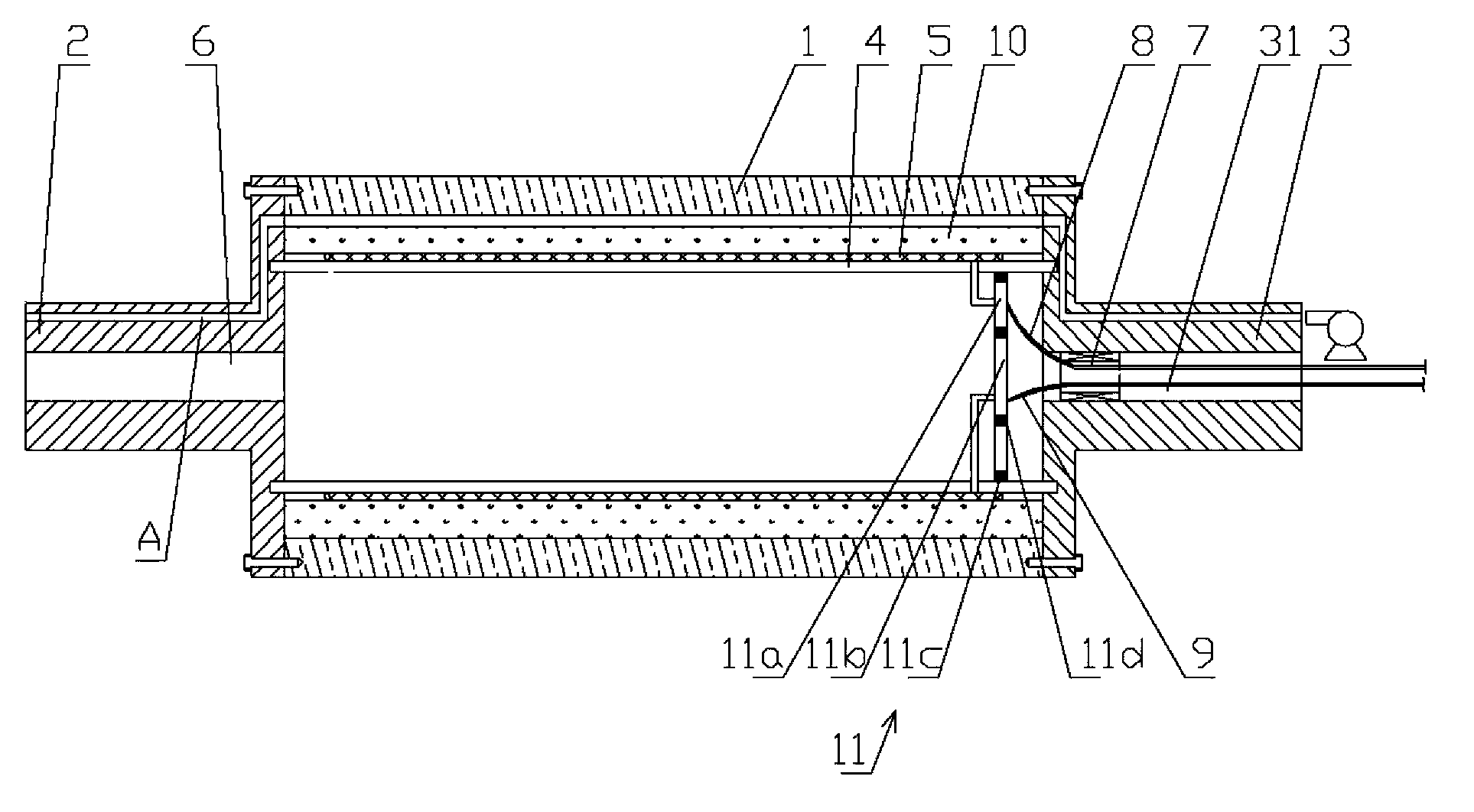

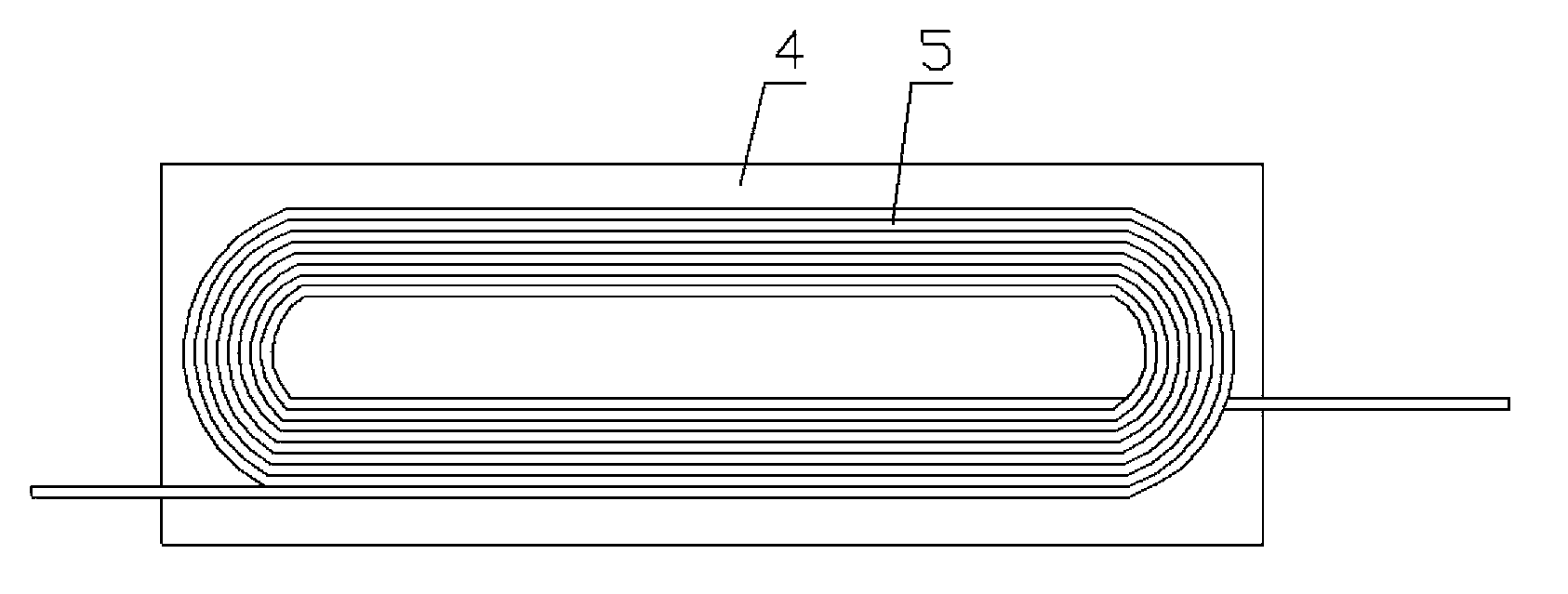

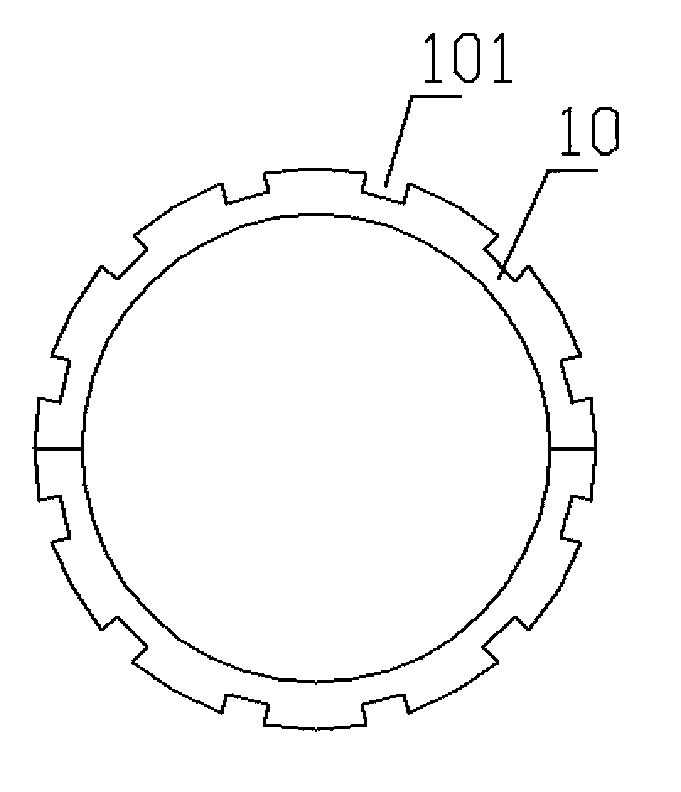

[0019] Example: see Figures 1 to 3 As shown, the built-in electromagnetic heating roller includes a roller 1, a left roller shaft 2 and a right roller shaft 3, and the two sides of the roller 1 are respectively fixed with a left roller shaft 2 and a right roller shaft 3 by screws, and a cylindrical substrate 4 An electromagnetic coil 5 is fixed on it, and the enameled wire terminals of the electromagnetic coil 5 protrude from the inner surface of the substrate 4 to be electrically connected with the positive connection plate 11a and the negative connection plate 11b on the power supply plate 11 respectively, and the positive connection plate 11a is fixed on the insulating outer ring 11c, the insulating outer ring 11c is fixed on the base plate 4, the insulating inner ring 11d is fixed on the inner ring of the positive contact plate 11a, the negative contact plate 11b is fixed on the insulating inner ring 11d, and the right roller shaft 3 is formed with a right The central thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com