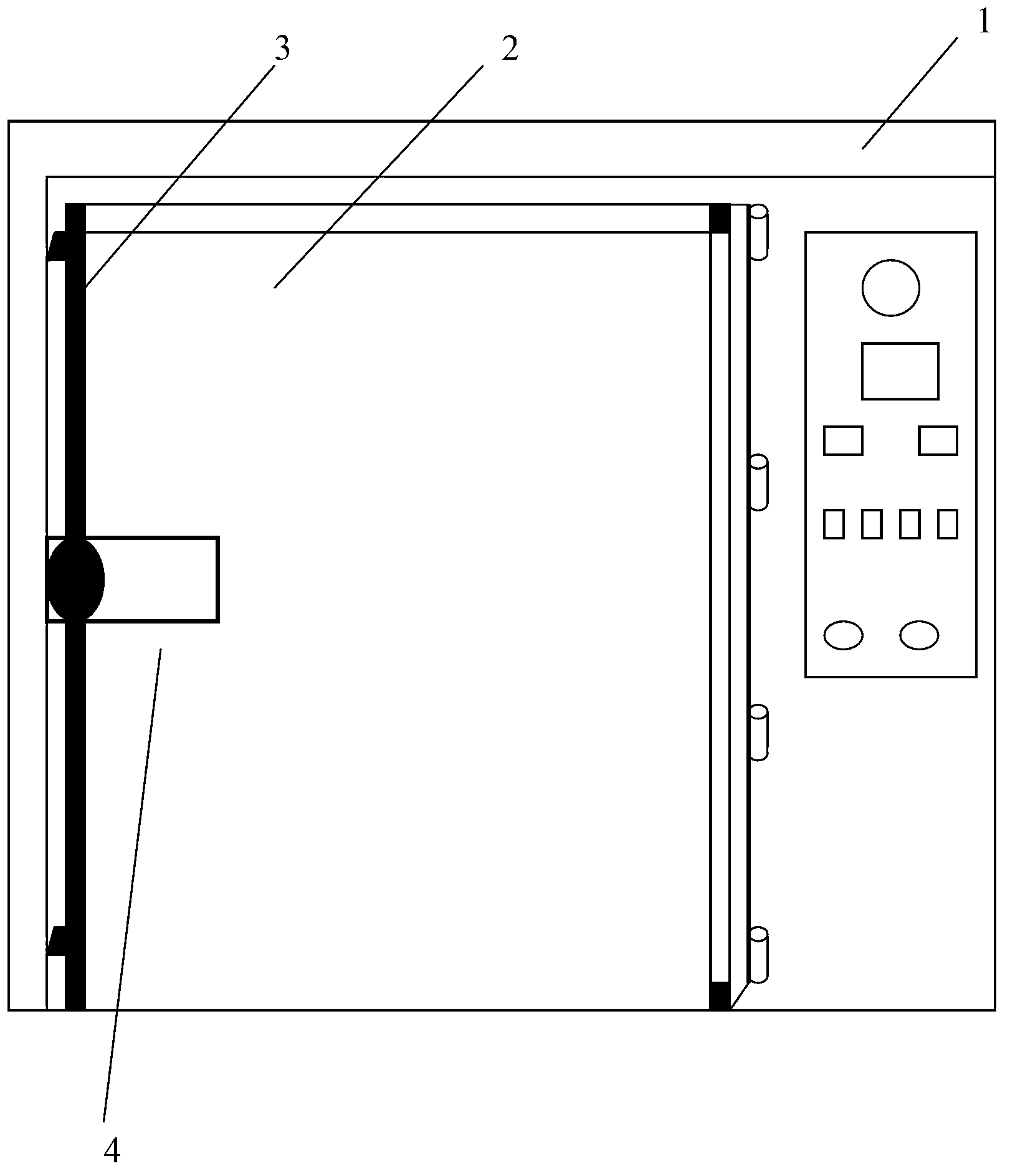

Vertical oven with automatic timed door opening device

An automatic door opening and oven technology, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve problems such as over-baking, scrapped circuit boards, and ink, to reduce work intensity, improve automation, and reduce scrap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

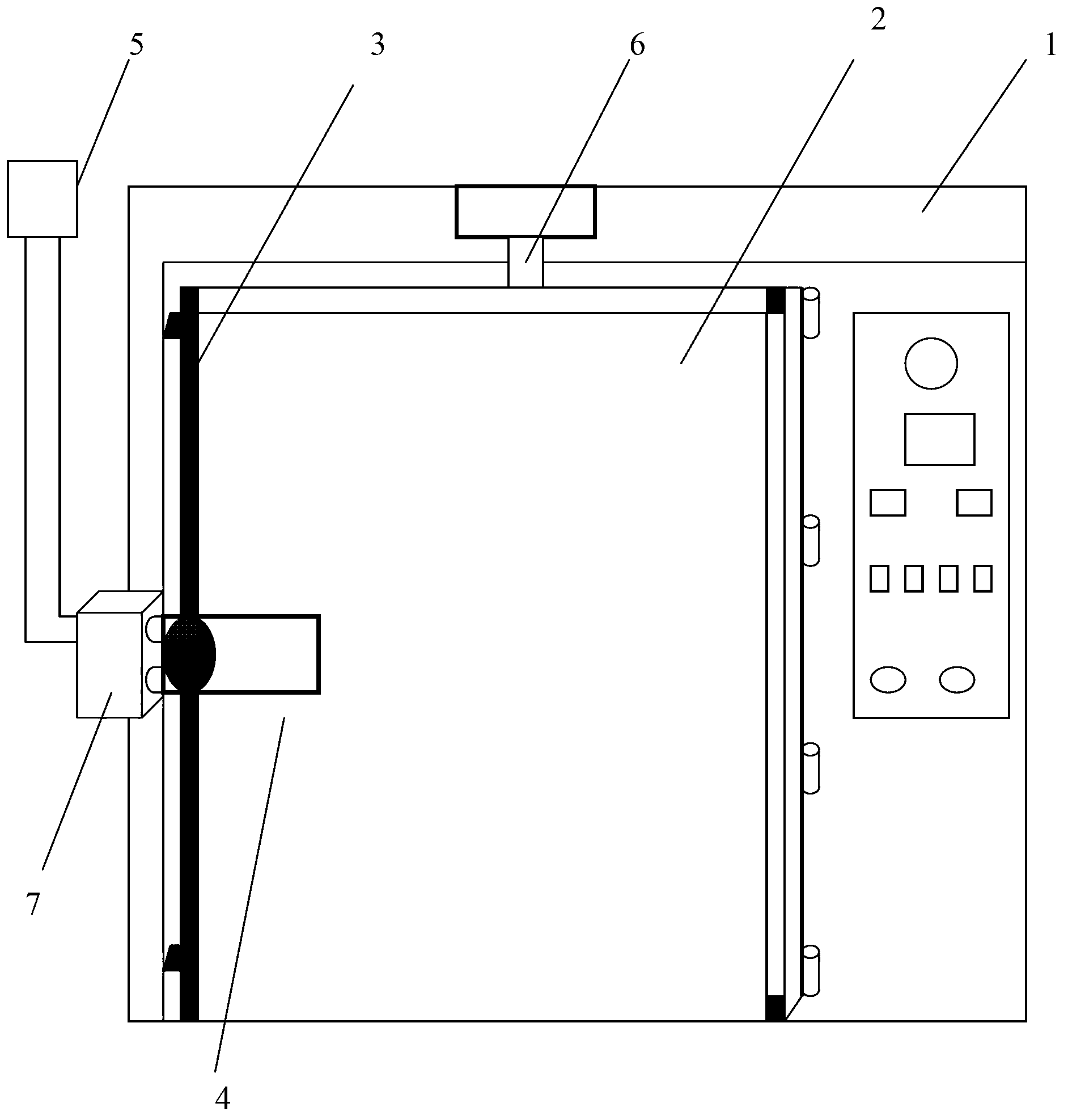

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] Such as figure 2 As shown, the present invention arranges a cylinder 7 on the oven body 1 of the vertical oven at a position opposite to the handle fixing block 4, and the cylinder 7 is connected to the pneumatic solenoid valve 5 through the exhaust port on the end cover, and the pneumatic solenoid valve 5 The control end is connected to the controller in the oven body 1. When the pneumatic solenoid valve 5 is opened, the piston rod of the cylinder 7 stretches out to withstand the handle fixing block 4, and the oven door 2 is pushed open. In the present invention, a shrapnel 6 is also provided on the oven body 1 where the edge of the oven door 2 is in contact with. When the oven door 2 is closed, the shrapnel 6 withstands the oven door 2. When the oven door 2 is pushed open, the The shrapnel 6 further bounces the oven door 2 outwards.

[0020] The working prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com