Liquid discharge head and recording device using same

A liquid ejection head, liquid technology, applied in the direction of inking device, printing, etc., can solve problems such as differences in displacement characteristics, and achieve the effect of reducing crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

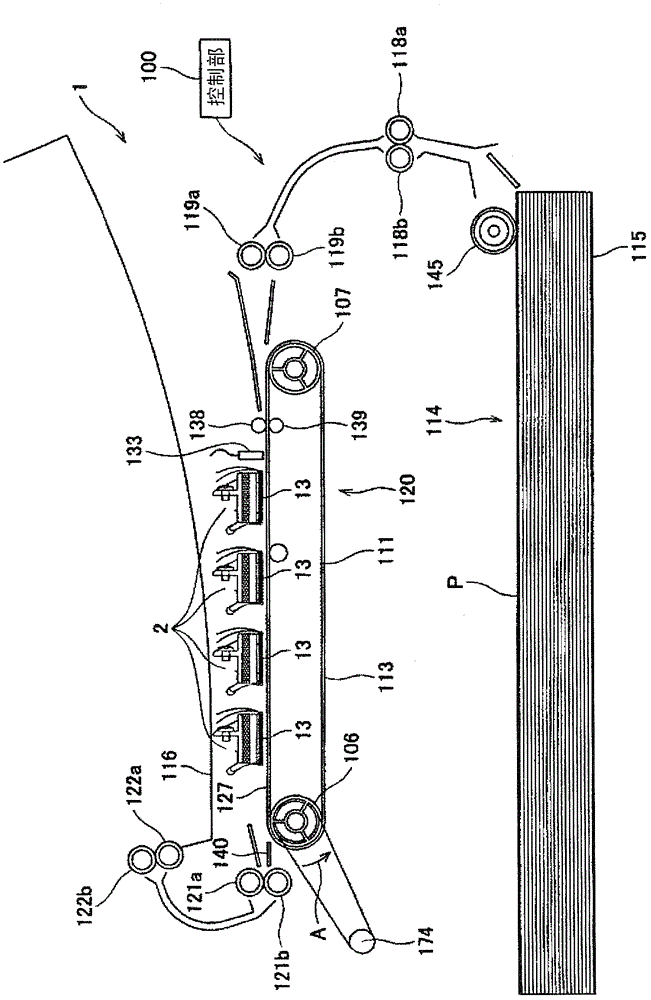

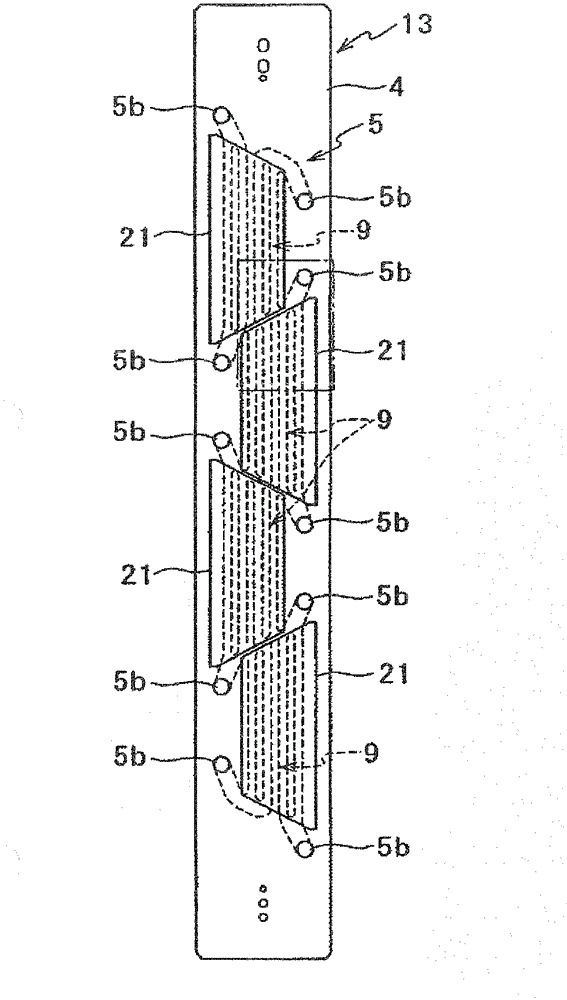

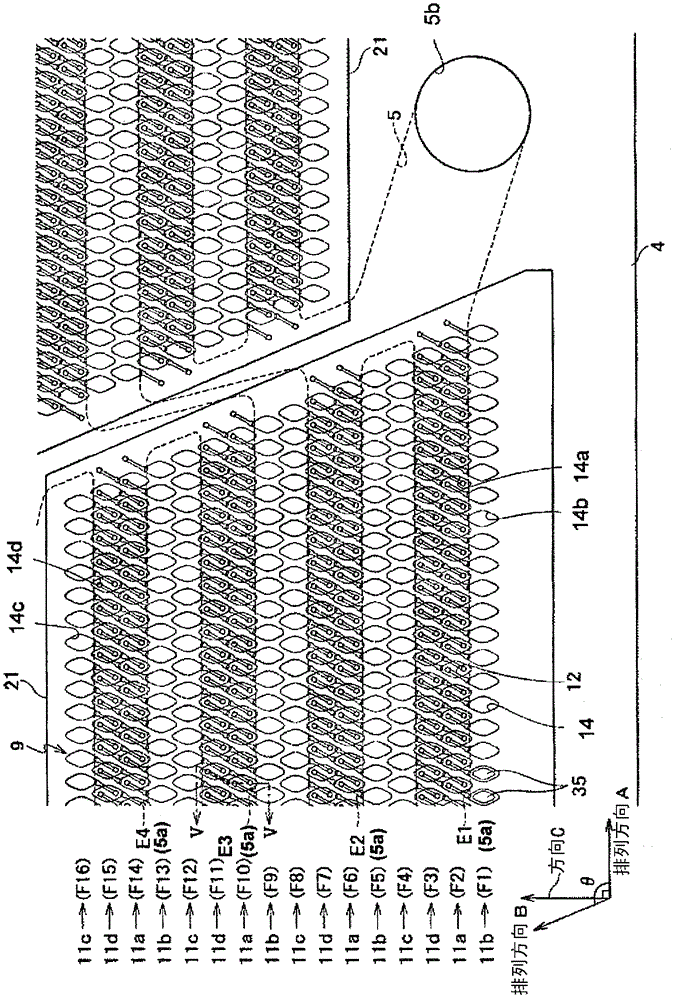

[0028] figure 1 It is a schematic configuration diagram showing an example of a recording device, that is, a color inkjet printer. This color inkjet printer 1 (hereinafter referred to as printer 1 ) has four liquid ejection heads 2 . These liquid ejection heads 2 are arranged along the conveyance direction of recording paper P as a recording medium, and are fixed to the printer 1 . The liquid ejection head 2 along the figure 1 The front has an elongated shape toward the depth direction.

[0029] In the printer 1 , along the conveyance path of the recording paper P, a paper feed unit 114 , a conveyance unit 120 , and a paper holder 116 are provided in this order. Further, the printer 1 is provided with a control unit 100 for controlling the operation of each unit of the printer 1 such as the liquid ejection head 2 and the paper feed unit 114 .

[0030] The paper feed unit 114 has a paper storage cassette 115 capable of storing a plurality of sheets of recording paper P, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com