Industrial vehicle control device

A technology for a control device and a working vehicle, which is applied to the control device, vehicle components, construction vehicles, etc., can solve problems such as improving fuel consumption, and achieve the effect of improving fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0021] Below, refer to Figure 1-Figure 9 A control device for a work vehicle according to a first embodiment of the present invention will be described.

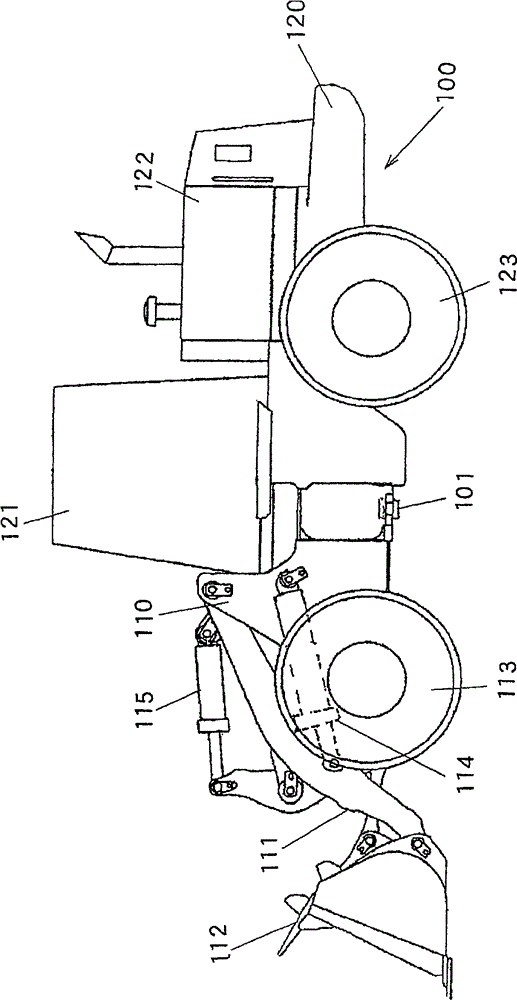

[0022] figure 1 It is a side view of a wheel loader as an example of a work vehicle to which the control device according to the present embodiment is applied. The wheel loader 100 is composed of a front body 110 having an arm 111 , a bucket 112 , tires 113 and the like, and a rear body 120 having a cab 121 , an engine compartment 122 , tires 123 and the like. The arm 111 is rotated vertically (pitch motion) by the drive of the arm cylinder 114 , and the bucket 112 is rotated vertically (dumping or scooping) by the drive of the bucket cylinder 115 . The front body 110 and the rear body 120 are rotatably connected to each other by a center pin 101 , and the front body 110 is bent left and right relative to the rear body 120 by expansion and contraction of a steering cylinder (not shown).

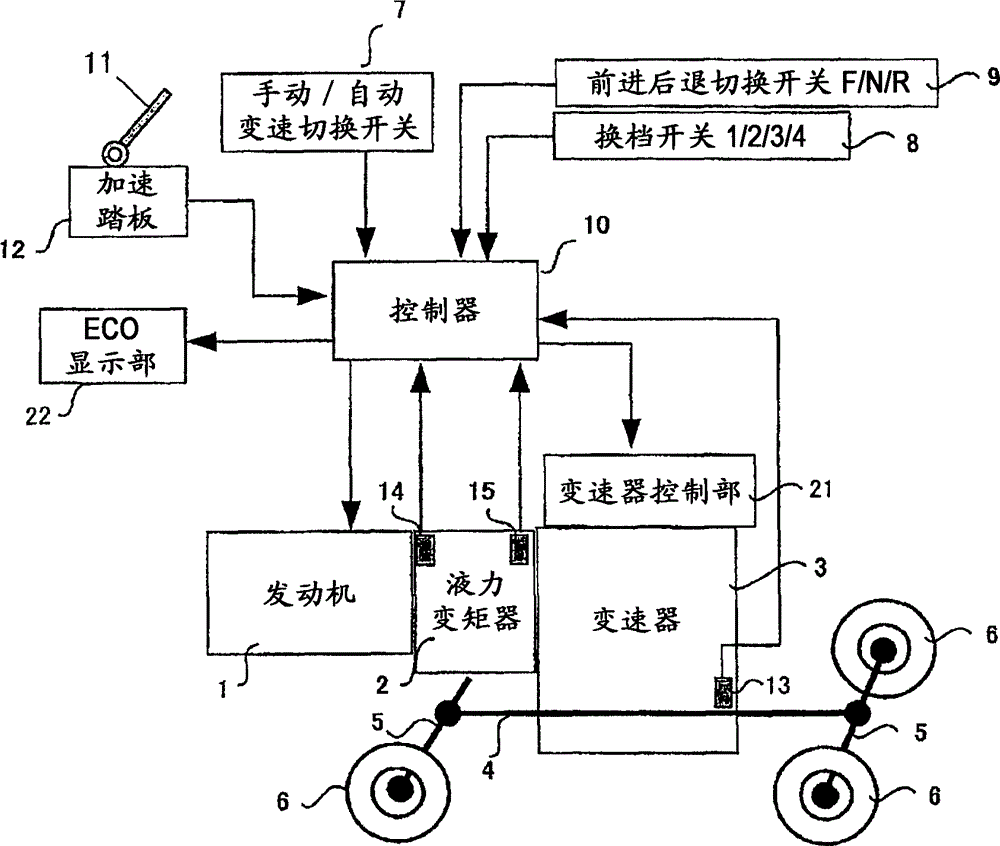

[0023] figure 2 It is a figure...

no. 2 Embodiment approach

[0052] A control device for a work vehicle according to a second embodiment will be described. The work vehicle control device of the second embodiment differs from the work vehicle control device of the first embodiment only in the processing in the controller 10 . Since other configurations are the same as those of the first embodiment, description thereof will be omitted, and the processing of the controller 10 will be described below.

[0053] Figure 10 It is a flowchart showing processing in the controller 10 in the second embodiment. Figure 10 with the first embodiment Figure 9 Corresponding. For the same as the first embodiment Figure 9 The same process is labeled with the same step number.

[0054] The processing shown in this flowchart starts, for example, from activation of the engine key switch, similarly to the first embodiment. In step S1, signals from various detectors 12-15 and switches 7-9 are read. In step S21, it is determined whether or not the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com