Valve driving device for internal combustion engine

A technology of valve drive and internal combustion engine, which is applied in the direction of valve device, machine/engine, engine lubrication, etc. It can solve the problems of lower output efficiency of internal combustion engine, high friction and wear, and large metal noise, etc., and achieve miniaturization and weight reduction , Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

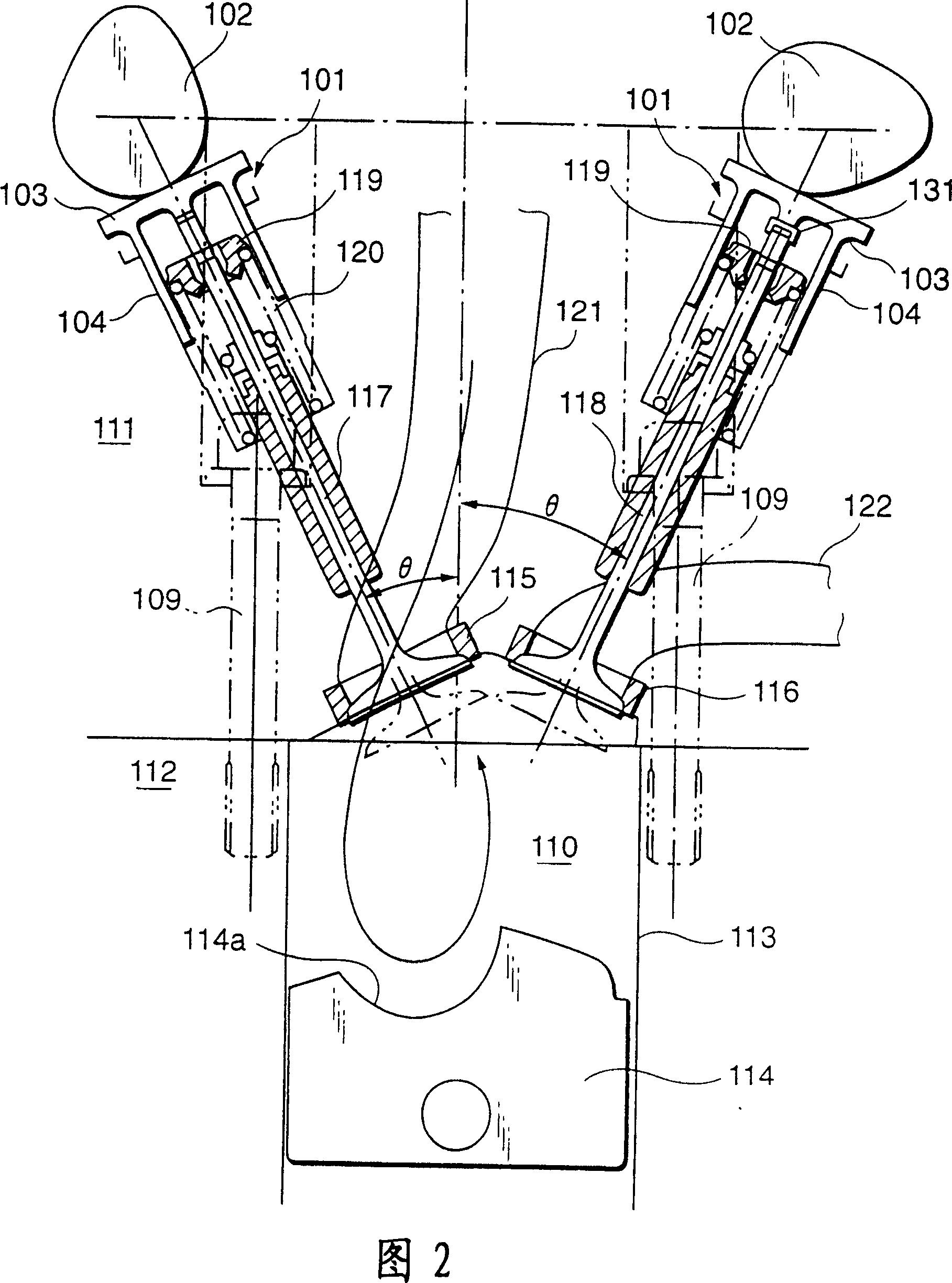

[0059] Now, a more detailed description of a preferred embodiment of the present invention will be given with reference to the accompanying drawings.

[0060] A valve driving device according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 3 .

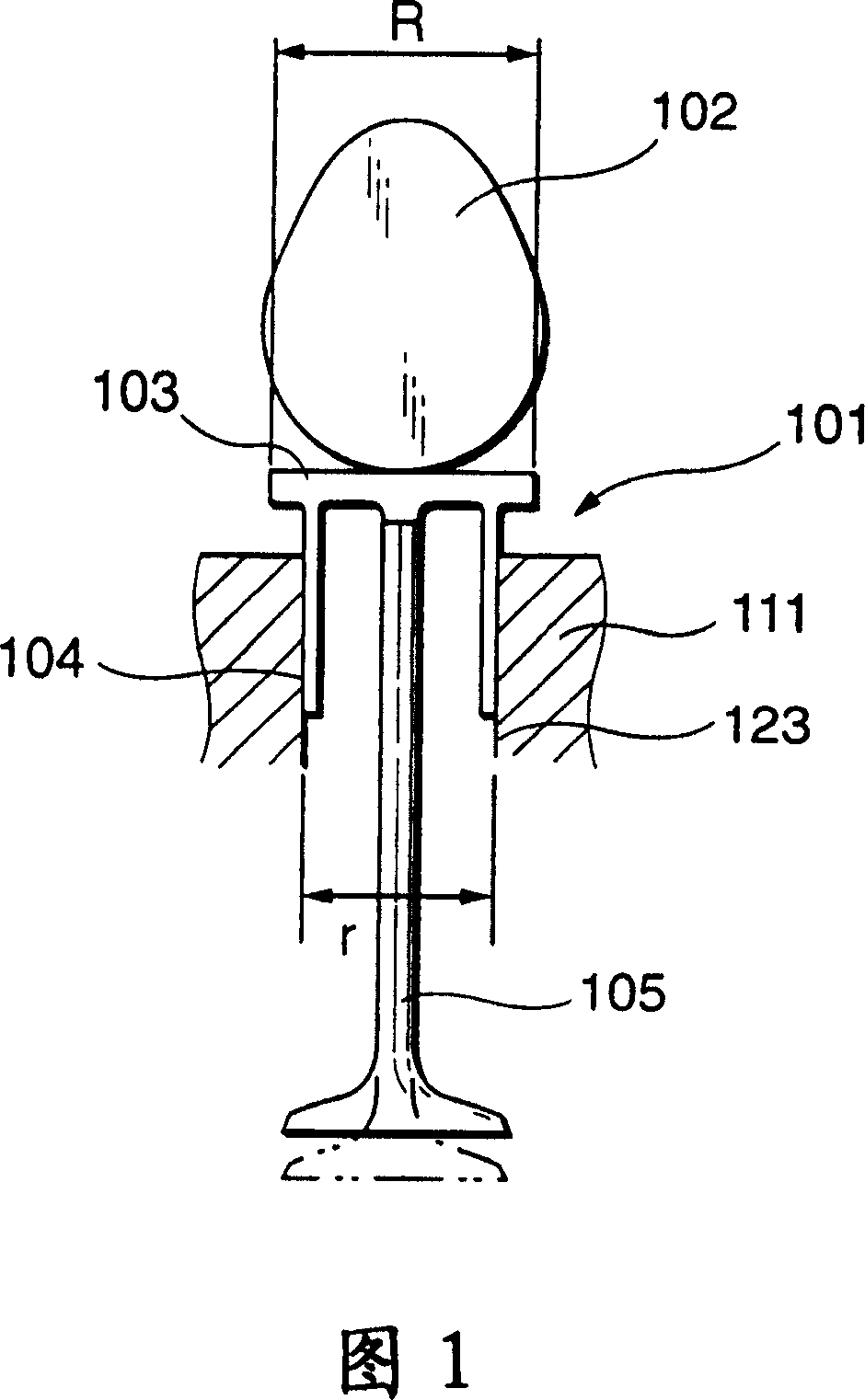

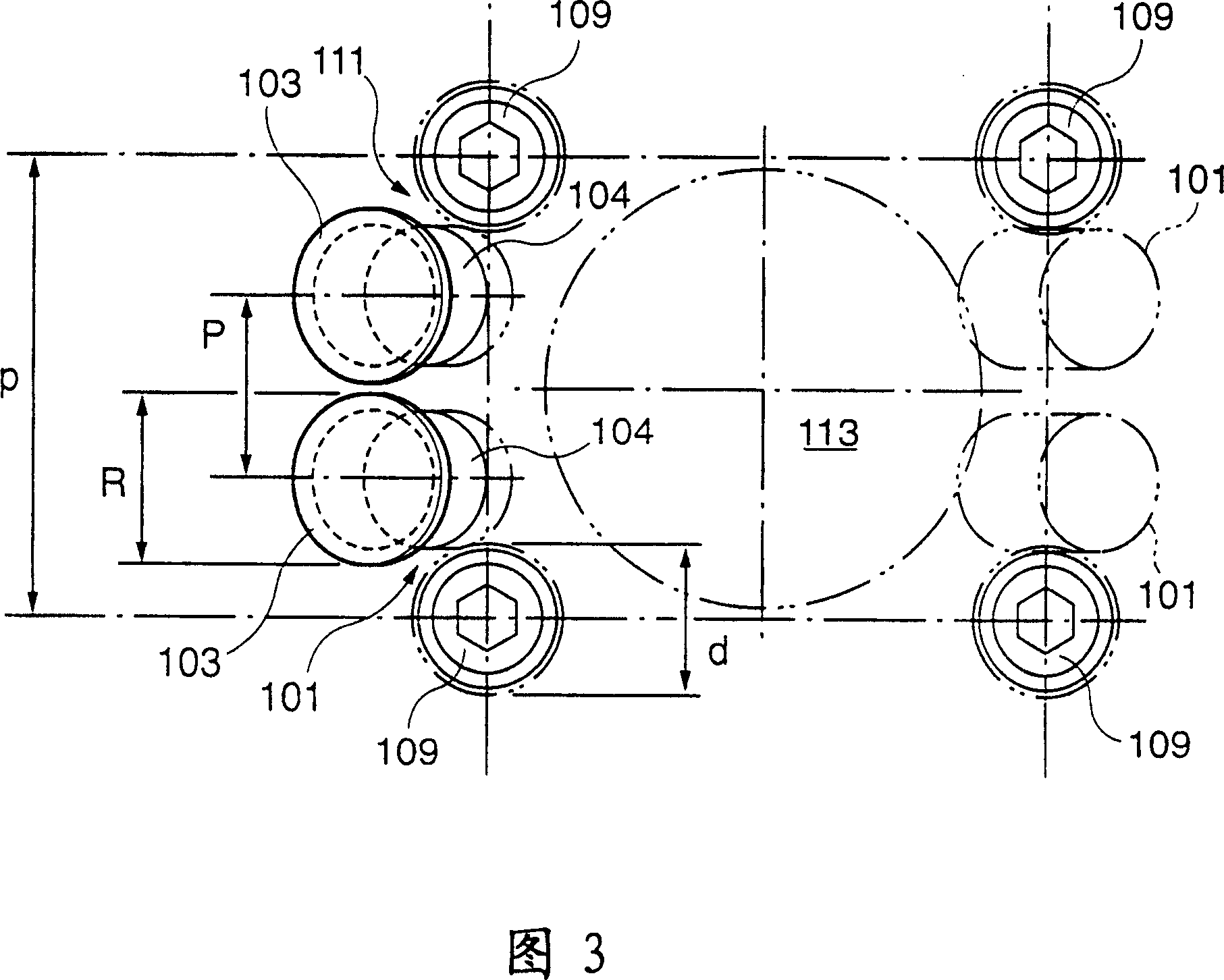

[0061] 1, the valve lifter 101 includes a lifter portion 103 in contact with a cam 102 provided on a cylinder head 111 of an internal combustion engine, and a portion of the lifter portion 103 in contact with the protruding portion of the cam 102 is made substantially Flat disc shape, the protruding part of the cam 102 is in line contact with the tappet part 103, the valve lifter 101 includes a hollow cylindrical guide part 104 continuous to the lower part of the tappet part 103, the guide part 104 is slidably placed on In the guide hole 123 of the cylinder head 111 , the diameter r of the guide portion 104 is set to be smaller than the diameter R of the tappet portion 103 .

[0062] Using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com