Technology for improving aroma of fumigated tea cream or tea powder by heating tea with hot air

A technology of hot air heating and tea, which is applied in the direction of tea spices, etc., can solve the problems of aroma loss and affecting the drinking value of tea paste, and achieve the effect of ensuring utilization and good taste absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

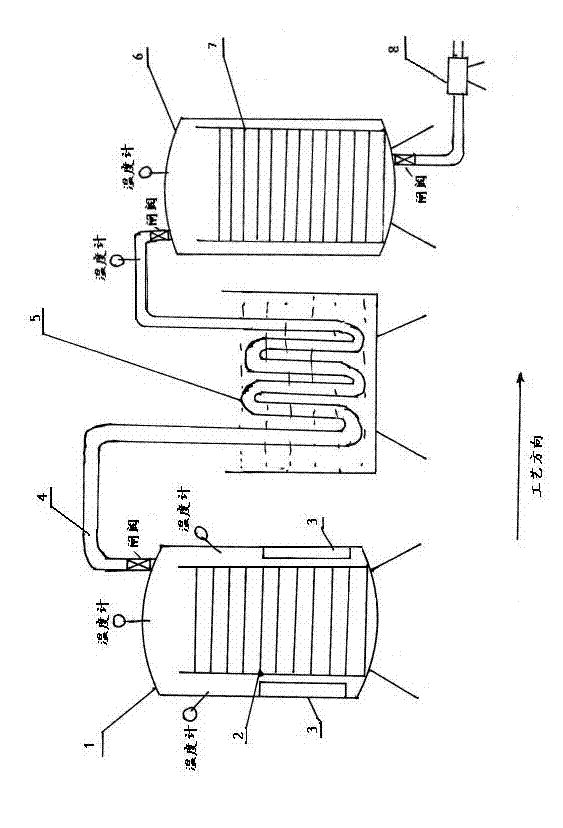

[0023] Embodiment one: fumigation of cooked tea paste or tea powder

[0024] Take 30 kg of ripe Pu-erh tea leaves with excellent aroma, and place them evenly on a shelf for placing tea leaves built with about 15 layers of stainless steel screens. The aperture of the screens is 60 mesh, and the thickness of each layer of tea leaves is 30 mm. Put the shelves for placing tea leaves in a closed stainless steel tea container with a volume of 500 liters, or other heat-resistant, odor-free containers that meet food processing requirements. Heat the air in the tea container in a closed environment, and control the heating of the hot air blower through the thermometer installed on the tea container: raise the temperature in the container to 85 degrees and keep it for at least 20 minutes; install a stainless steel valve with a gate valve on the top of the tea container The air-introduction pipe, the outlet end of the air-induction pipe is connected with the coil condenser, and the coil ...

Embodiment 2

[0026] Embodiment two: fumigation of raw tea paste or tea powder

[0027] Take 30 kg of raw Pu-erh tea leaves with excellent aroma, and place them evenly on a shelf for placing tea leaves built with about 15 layers of stainless steel screen mesh. The aperture of the screen mesh is 60 mesh, and the thickness of each layer of tea leaves is 30 mm. Put the shelves for placing tea leaves in a closed stainless steel tea container with a volume of 500 liters, or other heat-resistant, odor-free containers that meet food processing requirements. Heat the air in the tea container in a closed environment, and control the heating of the hot air blower through the thermometer installed on the tea container: raise the temperature in the container to 65-70 degrees and keep it for at least 20 minutes; install a gate valve on the top of the tea container Stainless steel air-introduction pipe, the outlet end of the air-induction pipe is connected with the coil condenser, the coil condenser is p...

Embodiment 3

[0029] Embodiment three: fumigation of black tea paste or tea powder

[0030] Take 30 kg of black tea leaves with excellent aroma, and place them evenly on a shelf for placing tea leaves built by about 15 layers of stainless steel screens. The aperture of the screen is 60 mesh, and the thickness of each layer of tea leaves is 40-50 mm. Put the shelves for placing tea leaves in a closed stainless steel tea container with a volume of 500 liters, or other heat-resistant, odor-free containers that meet food processing requirements. Heat the air in the tea container in a closed environment, and control the heating of the hot air blower through the thermometer installed on the tea container: raise the temperature in the container to 70 degrees and keep it for at least 20 minutes; install a stainless steel valve with a gate valve on the top of the tea container The air-introduction pipe, the outlet end of the air-induction pipe is connected with the coil condenser, and the coil conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com