Aerobic composting system and composting method thereof

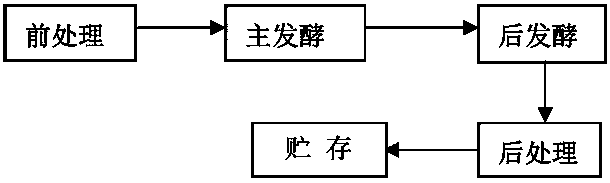

A kind of aerobic composting and composting technology, applied in the direction of organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of unoptimized balance and control, uncontrolled and eliminated, incomplete reactions, etc., and achieve extensive practical value. The operation is simple and practical, and the effect of eliminating gas odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

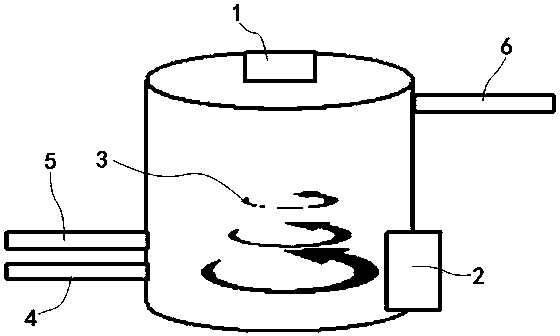

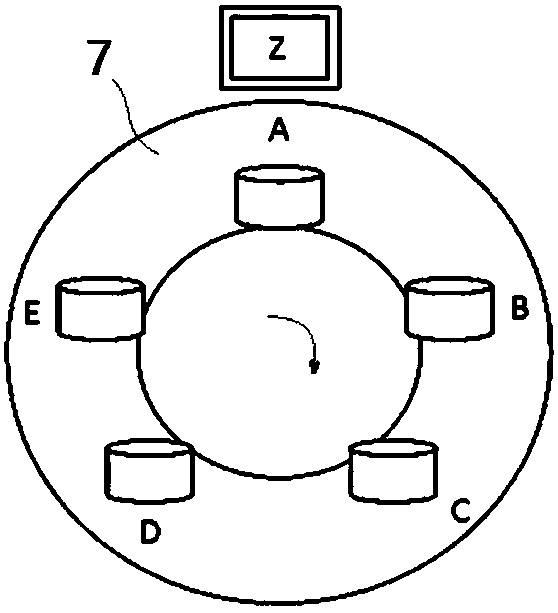

[0035] An aerobic composting system such as image 3 As shown, it includes a turntable 7 that can rotate horizontally, 3-5 bioreactors A, B, C, D, E that are circumferentially arranged on the turntable, and a feeding device and a discharge device that are arranged on one side of the turntable 7 and cooling exhaust tower; the bioreactors A, B, C, D, and E are connected in series through circulating air pipes to form a closed loop; the feeding device is used to send the materials to be composted into the corresponding bioreactors In the reactors A, B, C, D, E, the discharge device is used to take out the composted materials from the corresponding bioreactors A, B, C, D, E, and the cooling exhaust tower is used to Discharge and lower the temperature of the gas generated in each bioreactor A, B, C, D, E; each bioreactor has a detachable butt joint connection interface with the feed device, discharge device and cooling exhaust tower .

[0036] The invention provides a widely appl...

Embodiment 2

[0064] The difference from Example 1 is that in the design, the Z device can also move around several reactors sequentially, with the same effect. That is, the aerobic composting system includes a fixed plate, a plurality of bioreactors A, B, C, D, and E fixed on the fixed plate in the circumferential direction, and can be arranged on one side of the fixed plate to surround the circumferential direction of the fixed plate. Rotating feeding device, discharging device and cooling exhaust tower; each bioreactor A, B, C, D, E are connected in series by circulating air pipes to form a closed loop; the feeding device is used to The composted materials are sent to the corresponding bioreactors A, B, C, D, E, and the discharge device is used to take out the composted materials from the corresponding bioreactors A, B, C, D, E , the cooling exhaust tower is used to discharge and lower the temperature of the gas produced in each bioreactor A, B, C, D, E; each bioreactor has a feed device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com