Method for production of carbonized cloth, and carbonized cloth produced thereby

A manufacturing method, carbonized cloth technology, applied in textiles and papermaking, fiber chemical characteristics, heating/cooling fabrics, etc., can solve the problems of reduced electrical conductivity and thermal conductivity, unsatisfactory fiber softness, high density, etc. , to achieve good chemical resistance and washing resistance, excellent mechanical strength and softness, and improved mechanical strength and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] (manufacturing conditions)

[0097] A carbonized fiber cloth was produced under the following conditions.

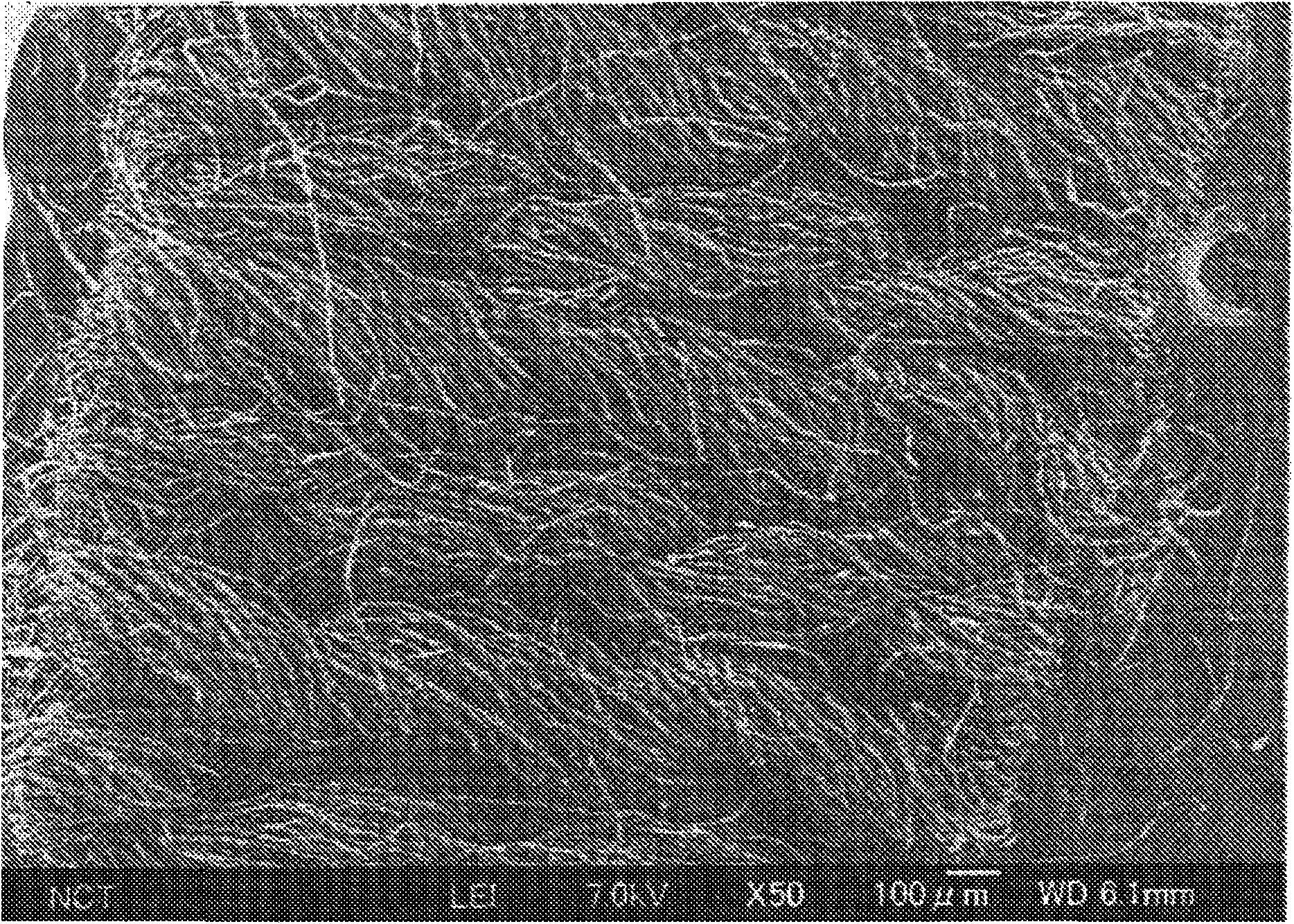

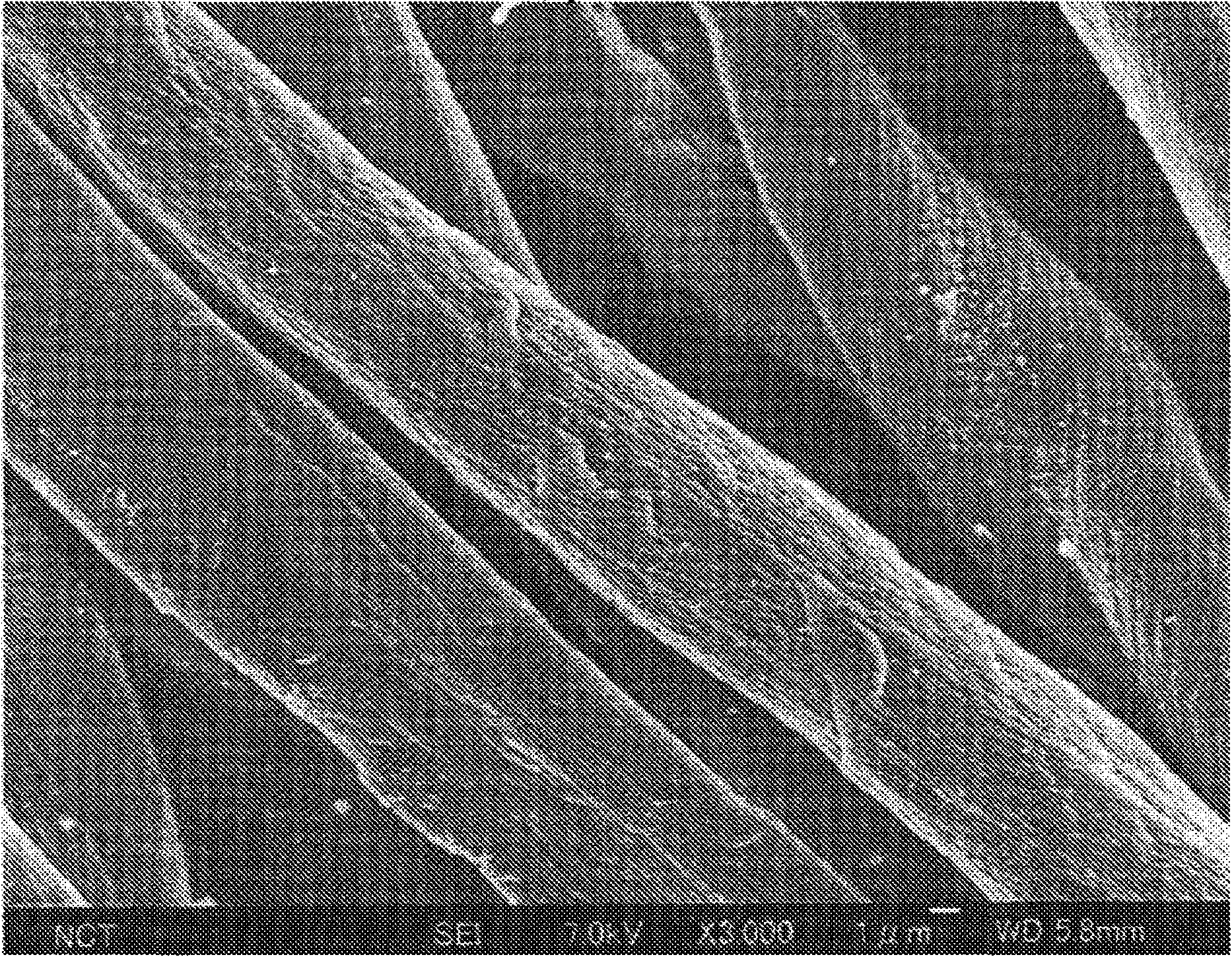

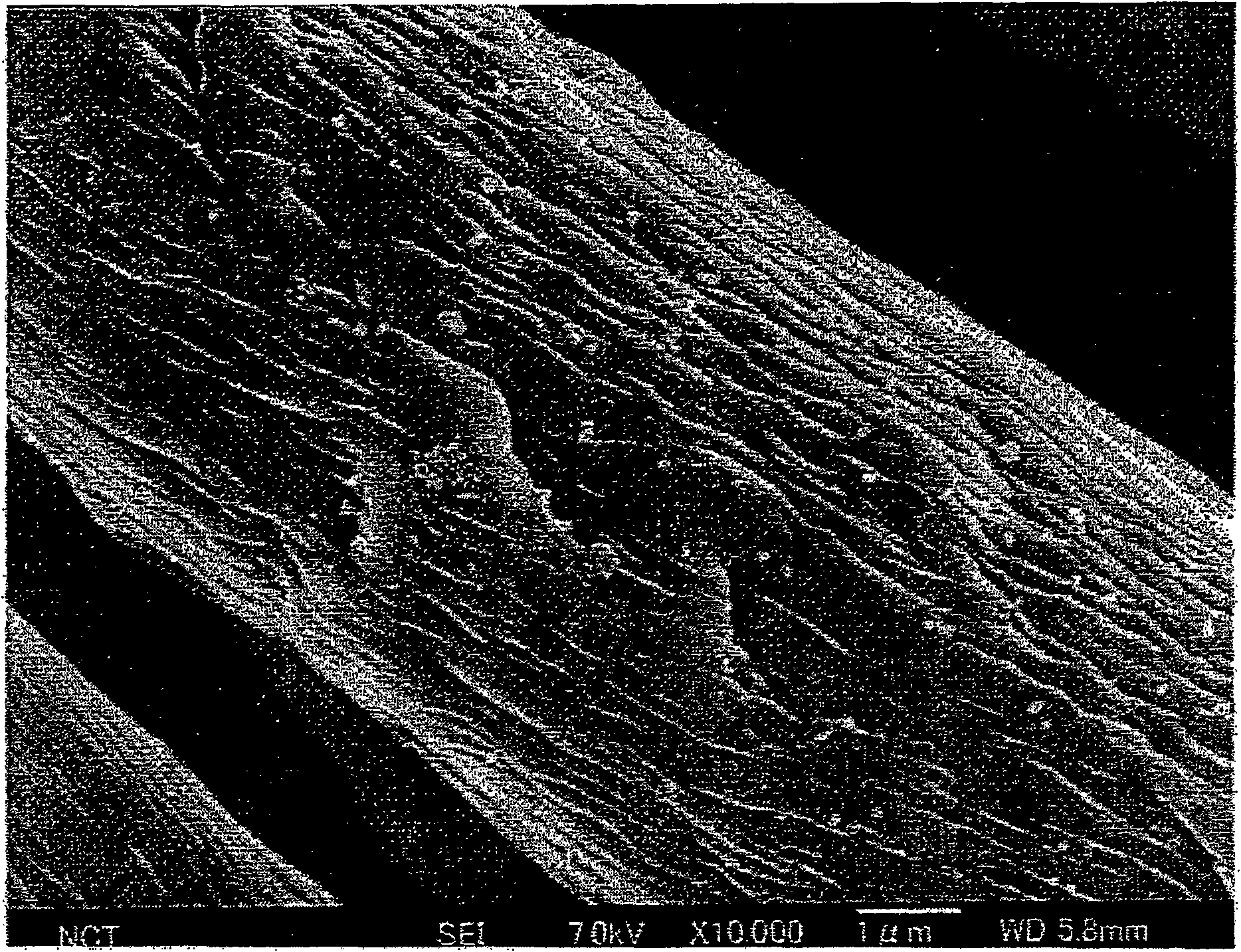

[0098] As a raw material, a cotton knit fabric (double-knit, manufactured by Kimura Textile Co., Ltd.) with a width of 115 mm and a thickness of 6 mm was used. Furthermore, the stiffness and softness of the cotton knitwear measured by a cantilever stiffness testing machine are 35 mm in the wale direction and 22 mm in the course direction. 300 layers of this cotton knitted fabric were laminated with a predetermined length, placed in a heating furnace, and heated under the following heating conditions to manufacture a carbonized fiber cloth.

[0099] Heating conditions: room temperature (15°C±20°C) ~ 1200°C heating rate 100°C / hour

[0100] The sum of heating holding time: 15 hours

[0101] Cooling: natural cooling

[0102] In addition, in an oxidizing atmosphere with an oxygen partial pressure of about 150mmHg immediately after the start of heating, in the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com