Ultrasonic postpositional unidirectional vibration turning method

A vibratory turning and ultrasonic technology, which is applied in the direction of fluid using vibration, can solve the problems of no vibration, failure, and unstable output of ultrasonic energy, and achieve the effect of guaranteed effect and stable vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

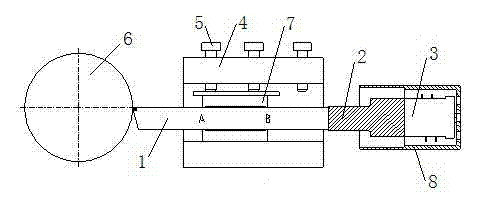

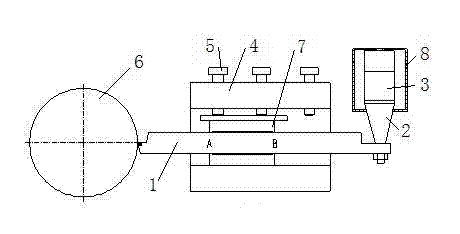

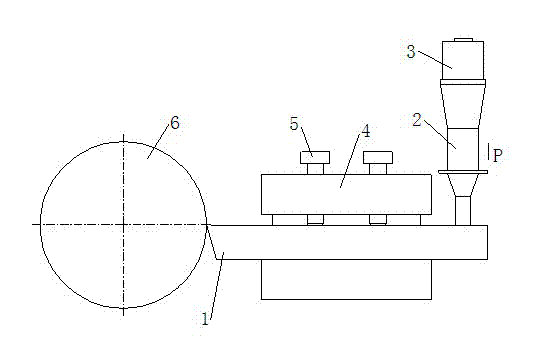

[0019] like image 3 Shown, the ultrasonic vibration turning method of the present invention and figure 1 and figure 2 The difference in the existing ultrasonic vibration turning technology given is that the horn and the cutter bar (or turning tool) were tightly connected in the past, but in the present invention, the horn 2 is pushed against the protruding installation of the turning tool. The rear portion other than the tool holder of the turning tool, the horn 2 is not fixedly connected with the turning tool 1, but only in contact. The horn 2 is connected to the transducer 3 to electrically connect the transducer to an external ultrasonic generator. During the turning process, a pressure is applied to the horn 2, and the pressure is applied to the horn 2. The pressure can be applied by a spring, a hydraulic mechanism or a pneumatic mechanism. The pressure acts on the tool bar of the turning tool 1 through the horn 2, so that there is always a pressure between the horn 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com