Automatic horizontal adjusting device and adjusting method for platform

A technology of automatic adjustment device and transmission device, used in transportation and packaging, elastic suspension, suspension and other directions, can solve the problems of slow response of hydraulic system, easy oil leakage, affecting the operating characteristics of the system, etc. The effect of quick return and shortened leveling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

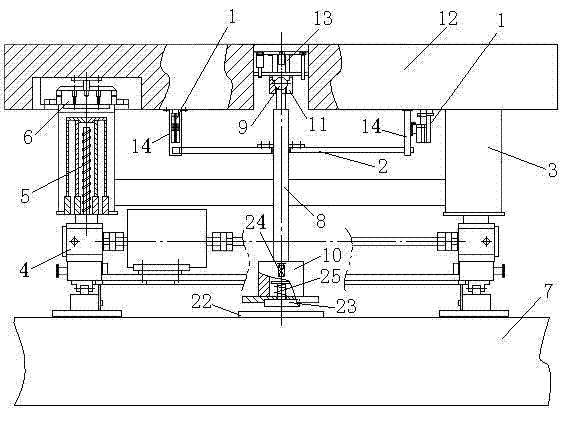

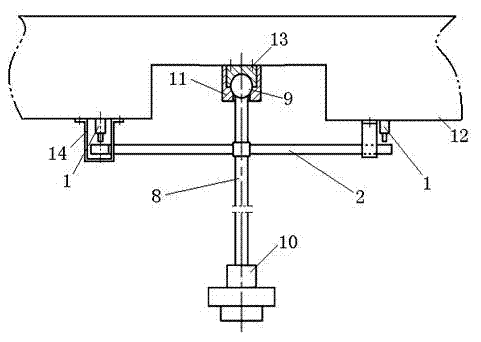

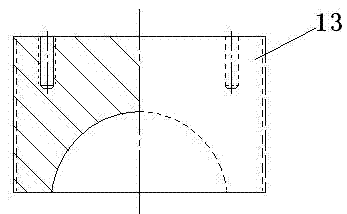

[0037] Example 2: Such as figure 1 , Figure 5 to Figure 7 , Another preferred embodiment of the present invention: a platform level automatic adjustment device, including a platform 12, air springs 6 are installed under the four corners of the platform 12, the air springs 6 and the lifts installed in the support legs 3 The upper end of the mechanism 5 is connected, and the lower end of the elevating mechanism 5 is connected with the transmission device 4, and the transmission device 4 drives the elevating mechanism 5 to adjust the platen 12. A support B15 is installed at the middle position below the platen 12. The support B15 is composed of a seat body 16, a pole 17 and a ball head B26. The center of the seat body 16 is fixed with a pole 17, and the end of the pole 17 is a ball head B26. , The pole 17 is sleeved with a snap ring 18 . The snap ring 18 is circular, with threads on the outer periphery, and a concave arc surface matching the shape of the ball head B26 on the...

Embodiment 3

[0039] Example 3: A platform level automatic adjustment device, the cantilever 2 is in the shape of "Y", see Figure 9 , and the connecting line of its ends is an equilateral triangle or an isosceles triangle. Others are identical with embodiment 1 or embodiment 2.

Embodiment 4

[0040] Example 4: An automatic adjustment device for platform level, the cantilever 2 is in the shape of a "ten", and the connection line at the end is in the shape of a square or a rhombus. Others are identical with embodiment 1 or embodiment 2.

[0041] The steps of the adjustment method of an automatic platform level adjustment device in the present invention are as follows: first, the joint connection between the dead weight of the plumb weight 10 and the center of the swing rod 8 is used, and when the horizontal position of the platform 12 deviates, the swing rod 8 will always Pointing to the center of the earth, now the cantilever 2 keeps the horizontal position all the time. The vehicle-mounted platform has four supporting legs 3, which are divided into three groups, one of which includes two supporting legs 3, and three regulating air valves 1 respectively control the corresponding air springs 6, so as to control the lifting of the air springs 6 in the supporting lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com