Resin for water-soluble anode electrophoretic paint and preparation method of resin

A kind of anodic electrophoretic paint, water-soluble technology, applied in the field of resin, can solve the problems of high raw material and production costs, unpainted paint, too thick paint film, etc., to achieve the effect of eliminating poisoning, improving paint quality, and reducing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described water-soluble anodic electrophoretic paint resin comprises the following steps:

[0029] 1) Condensation reaction: 56-63 parts of cardanol are put into a stainless steel reaction kettle with a condenser, then 7-12 parts of formaldehyde with a concentration of 37%, 1.9-2.6 parts of hexamethylenetetramine, 3 part of toluene, seal the feeding port, open the vent valve, pass nitrogen, heat up and stir, adjust the pH value to 8-8.5, the condensation reaction temperature is 65-140°C, turn off the nitrogen, measure the viscosity in the central control, 25°C water bath format viscosity When it reaches 14-16 seconds, it is the end point of condensation, and the stirring is stopped;

[0030] The suitable temperature for the condensation reaction is 65-140°C, and the suitable pH value is 8-8.5. If the pH value is low, the condensation reaction is slow, and the resin is not easy to be transparent; if the pH value is high, the condensation reacti...

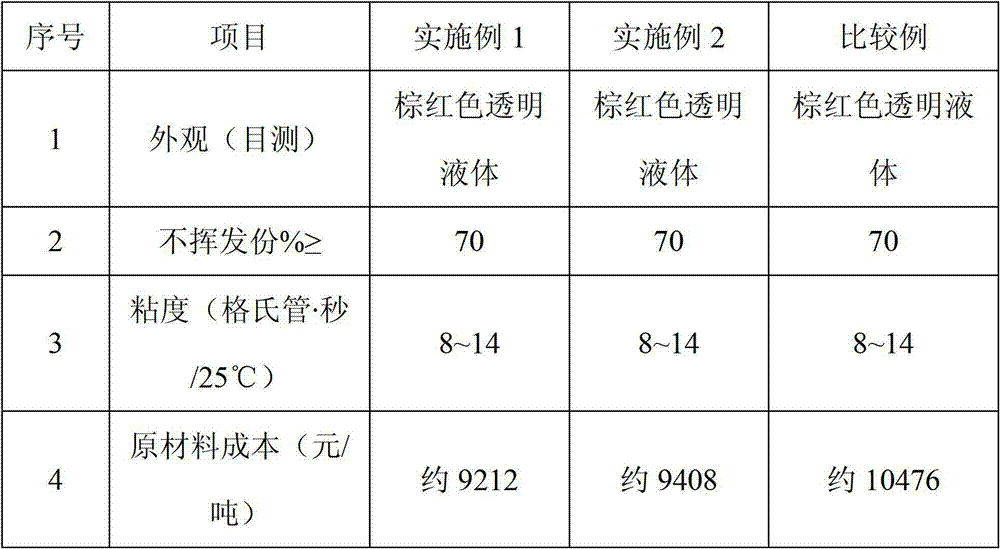

Embodiment 1

[0036] 57 parts of cardanol are dropped into a stainless steel reactor with a condenser, then 12 parts of formaldehyde with a concentration of 37%, 2.6 parts of hexamethylenetetramine (preferably hexamethylenetetramine and formaldehyde are miscible Then add to the reaction kettle), 3 parts of toluene (additional), seal the feeding port, open the vent valve, pass nitrogen, heat up and stir, adjust the pH value to 8-8.5, and pay attention to the expansion of the pot at 100±2°C , turn off the nitrogen at 120°C, and after 15 minutes at 138±2°C, measure the viscosity in the central control (resin: D 40 =8:2, Grignard tube / 25°C), the condensation end point is when the viscosity reaches 14-16 seconds in a water bath at 25°C; stop stirring, quickly add 8 parts of maleic anhydride, keep warm at 150°C for 20-30 minutes, and cool down Add 15 parts of butanol below 110°C, add 5.4 parts of monoethanolamine below 100°C, adjust the pH value to 8-8.5, stir for 20-30 minutes, and pack for late...

Embodiment 2

[0038] 63 parts of cardanol are dropped into a stainless steel reaction kettle with a condenser, then 7 parts of formaldehyde with a concentration of 37%, 1.9 parts of hexamethylenetetramine (preferably hexamethylenetetramine and formaldehyde are well miscible) Then add to the reaction kettle), 3 parts of toluene (additional), seal the feeding port, open the vent valve, pass nitrogen, heat up and stir, adjust the pH value to 8-8.5, and pay attention to the expansion of the pot at 100±2°C , turn off the nitrogen at 120°C, and after 15 minutes at 138±2°C, measure the viscosity in the central control (resin: D 40 =8:2, Grignard tube / 25°C), the condensation end point is when the viscosity reaches 14-16 seconds in a water bath at 25°C; stop stirring, quickly add 5 parts of maleic anhydride, keep warm at 150°C for 20-30 minutes, and cool down Add 18 parts of butanol below 110°C, add 5.1 parts of monoethanolamine below 100°C, adjust the pH value to 8-8.5, stir for 20-30 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com