Coal-to-liquid synthetic base drilling fluid with constant rheological property in deep water

A synthetic base and drilling fluid technology, which is applied in the petroleum industry, drilling compositions, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as pressure control, achieve cost reduction, low biological toxicity, and improve working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

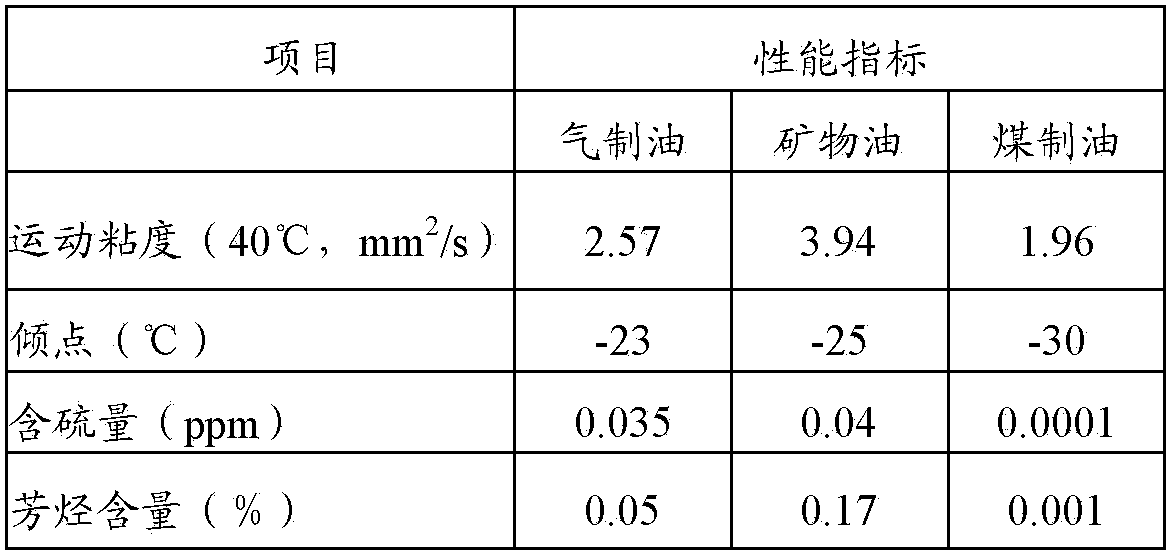

[0033] The coal oil provided by Beijing Shengshi Rongzhuang Chemical Technology Research Institute is selected. Its preparation method is as follows: the raw coal is reacted with oxygen and water vapor to gasify all the coal, and the crude gas obtained is converted, desulfurized, and decarbonized into H 2Clean synthesis gas with a / CO volume ratio of 1.2~2, under the conditions of 2~5MPa, 200°C~295°C, add catalyst and its carrier, and make the synthesis reaction of the synthesis gas by Fischer-Tropsch method to generate hydrocarbons compound; then rectifying the synthesized hydrocarbon compound at 160-300°C to obtain C9-C24 normal alkanes, adding a flow regulator to the normal alkanes so that the mass fraction of the flow regulator is 2% ~5%, the coal-to-oil is obtained.

[0034] The coal-to-oil was analyzed for components, and found through analysis: the coal-to-oil used in the present invention is mainly composed of C9~C24 n-alkanes and a flow regulator, wherein the content...

Embodiment 2

[0040] a. formula: the coal-to-oil (synthetic base liquid) of embodiment 1: 70 parts by volume;

[0041] Aqueous calcium chloride solution with a mass fraction of 25%: 30 parts by volume; and

[0042] Calculate based on the total volume (100 parts) of coal-to-oil and calcium chloride aqueous solution,

[0043] The organic soil has a mass volume ratio of 2.8%, wherein the organic soil is a product formed by modifying bentonite with an alkyl quaternary ammonium salt with a long chain (C12-C30).

[0044] The emulsifier has a mass volume ratio of 3.0%, wherein the emulsifier is formed by mixing a main emulsifier and an auxiliary emulsifier in a mass ratio of 3:1. The main emulsifier is a mixture of palmitic acid and oleic acid, the condensate of EO / PO and propylene glycol, and tall oil amide in a mass ratio of 3:1:2, and the hydrophobic group of the condensate of EO / PO and propylene glycol The molecular weight of the group is 1800; tall oil amide is the product of the reaction o...

Embodiment 3

[0051] a. formula: the coal-to-oil (synthetic base liquid) of embodiment 1: 80 parts by volume;

[0052] Mass fraction is 25% calcium chloride aqueous solution: 20 parts by volume;

[0053] Calculate based on the total volume (100 parts) of coal-to-oil and calcium chloride aqueous solution,

[0054] The organic soil has a mass volume ratio of 2.5%, wherein the organic soil is a product formed by modifying bentonite with an alkyl quaternary ammonium salt with a long chain (C12-C30).

[0055] The emulsifier has a mass volume ratio of 2.8%, wherein the emulsifier is formed by mixing the main emulsifier and the auxiliary emulsifier in a mass ratio of 3:1. The main emulsifier is a mixture of palmitic acid and oleic acid, the condensate of EO / PO and propylene glycol, and tall oil amide in a mass ratio of 3:1:2, and the hydrophobic group of the condensate of EO / PO and propylene glycol The molecular weight of the group is 1800; tall oil amide is the product of the reaction of tall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com