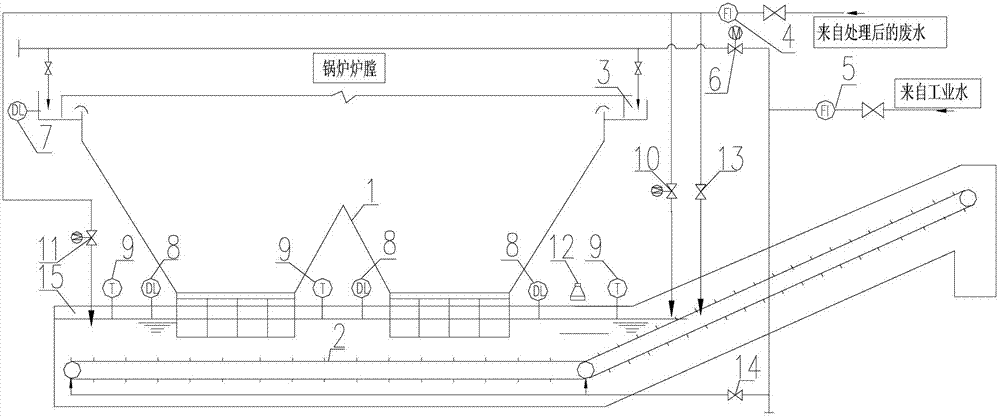

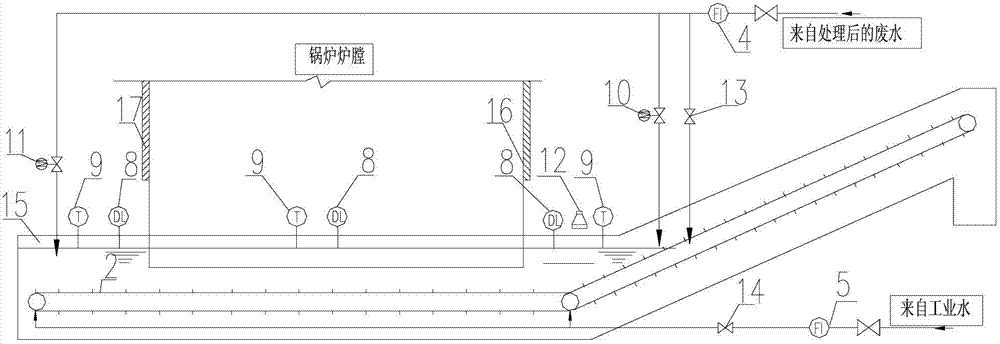

Slag water self-balancing heat exchange method of water-cooled mechanical slag-removal system in thermal power plant

A thermal power plant, water-cooled technology, applied in the thermal power plant water-cooled mechanical slag removal system slag-water self-balanced heat exchange field, can solve the problems of complex operation, high energy consumption, and many equipment, and achieve system simplification and simple operation , the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the prior art, when the mixed water temperature is not higher than 60°C in the three heat exchange methods, the slag water burst and radiative evaporation are limited, and the hot slag cooling does not make full use of the latent heat of vaporization of the slag water, and the cold slag water needs to continuously overflow The slag scraper performs external auxiliary cooling. In order to overcome the deficiencies of the above three slag water circulation systems, the method of the present invention provides a water-cooled mechanical slag removal system cold slag water self-balance heat exchange scheme: that is, no slag water circulation treatment system is installed for external cooling , The slag removal machine adopts the operation mode of no overflow of slag water and maintaining water level, allowing the operation of the slag removal machine with a water temperature exceeding 60°C. Laboratory and field tests have found that when the amount of slag is constant and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com