Method for determining air-leakage rate of oxidized zone of goaf

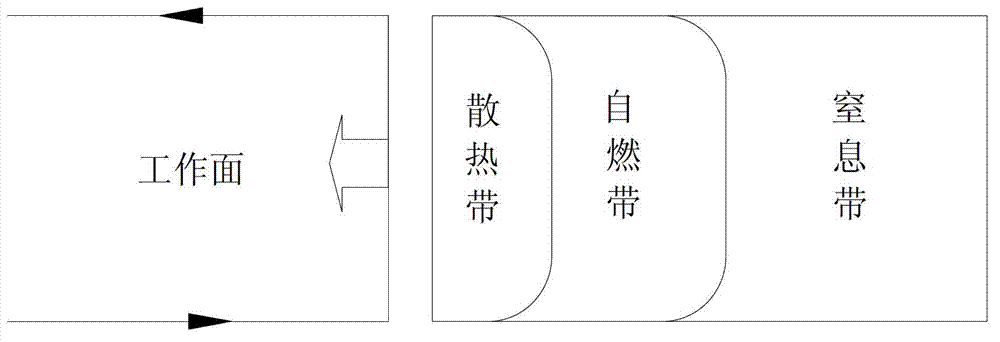

A determination method and goaf technology, which is applied in the prevention and control of coal spontaneous combustion in the goaf of the coal mine mining face, and in the field of determination of air leakage in the oxidation zone of the goaf, can solve the difficulty of air leakage in the oxidation spontaneous combustion zone of the goaf, The technical work of fire prevention and extinguishing lacks basis and affects the technical work of fire prevention and extinguishing, and achieves extensive social and economic benefits, scientific and reasonable mine fire prevention and extinguishing work, and optimization of fire prevention and extinguishing technical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] A method for determining the air leakage volume of an oxidation zone in a gob, specifically comprising the following steps:

[0041] Step 1: Firstly, according to the natural conditions of coal seam occurrence on site, the empirical values of production, gas volume, air leakage in gobs and the actual use of nitrogen injection machines on site are used to determine the flow rate of nitrogen injection in the working face; application, the nitrogen injection flow rate is 390m in a fully mechanized caving mining face 3 / h.

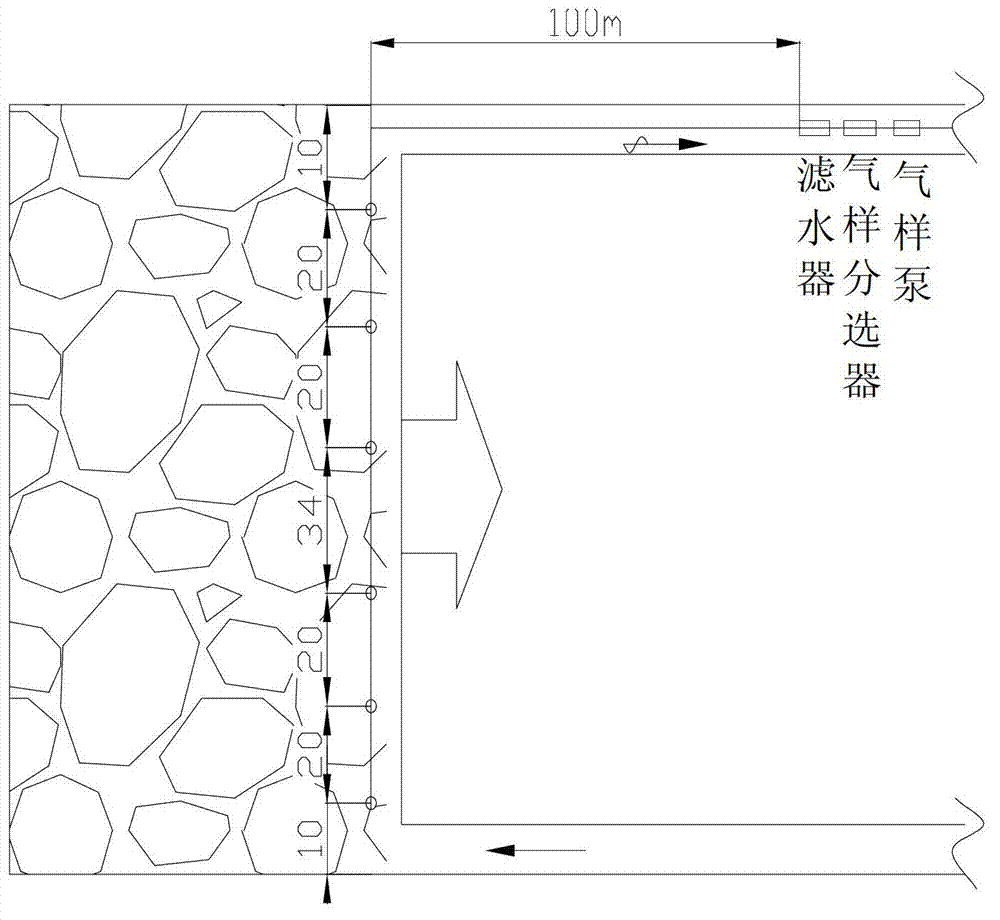

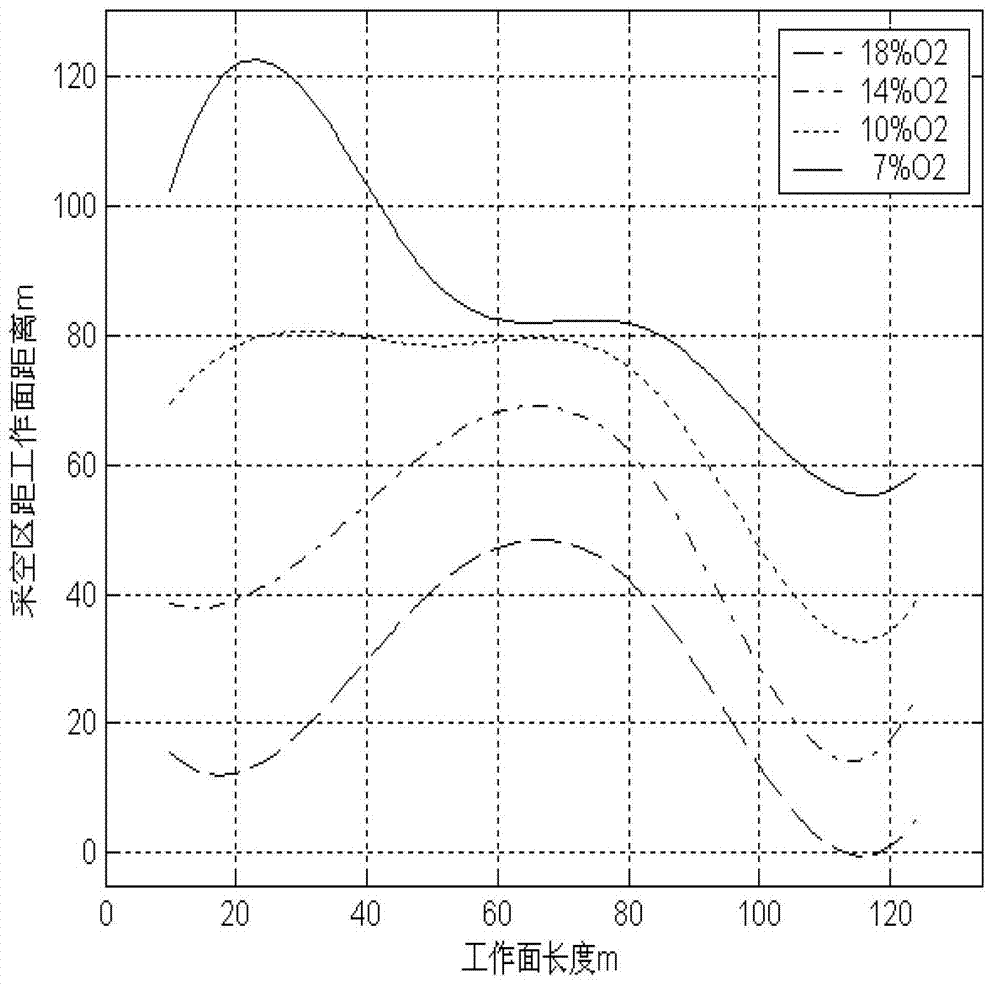

[0042] Step 2: Observing the gas composition of the buried bundle pipes in the goaf. The measuring points should be arranged parallel to the working face and distributed in the middle of the goaf; the number of measuring points should be reasonably determined according to the length of the working face. The length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com