Power chassis of double crawler belt-type micro tillage machine

A power chassis and crawler-type technology, which is applied in the field of field micro-cultivation management machines, can solve the problems of easy deformation of the gearbox, large traction resistance of equipment, and difficult operation, so as to improve operation stability, reduce operation difficulty, and strong climbing ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention can be explained in more detail by referring to the accompanying drawings and the following embodiments, and the present invention is not limited to the combination of the following embodiments.

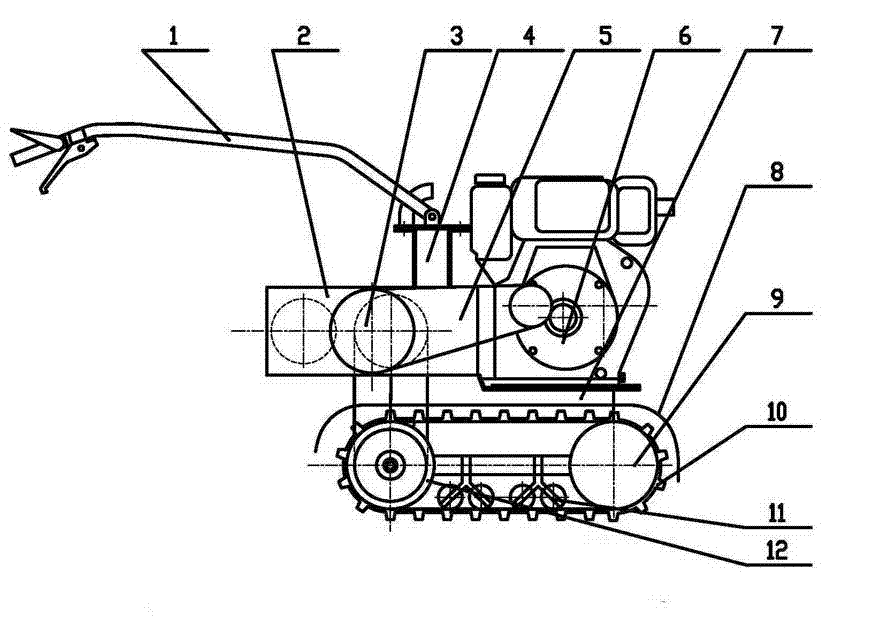

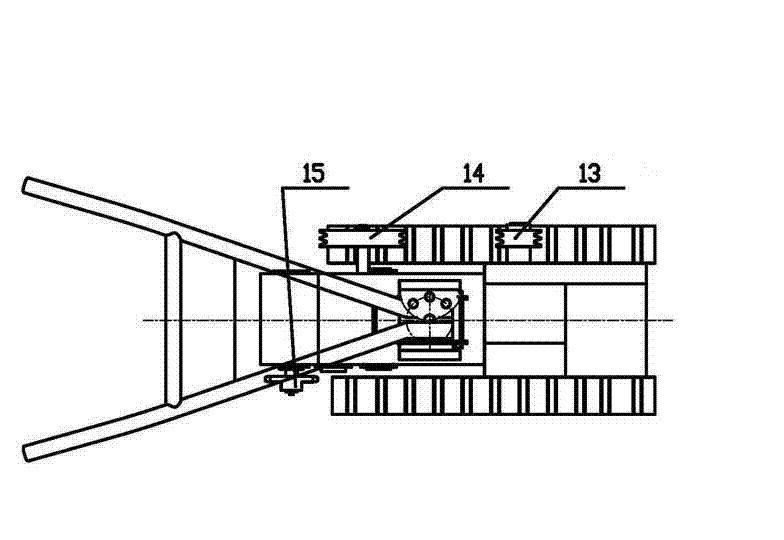

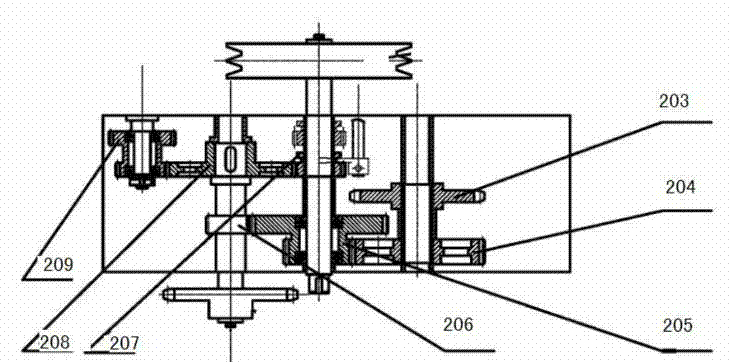

[0020] As shown in the figure, a power chassis of a double-crawler micro-cultivator includes an engine 6 and a frame 7. On the frame 7, an armrest 1 and an armrest platform 4 are also provided, and a belt transmission mechanism 5, a gearbox 2, The chain transmission mechanism 3 and the crawler belt running mechanism arranged at the bottom of the frame 7, the power output of the engine 6 is transmitted to the gearbox 2 through the belt transmission mechanism, and the power is divided into two outputs after the gearbox 2 changes speed, and the power output of one path is to The crawler belt drive wheel in the crawler belt traveling mechanism drives the whole chassis to walk, and another part of the power is sent to the chain transmission mechanism 3, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com