Intelligent study system and computational study method for hot rolled strip width control models

A technology of width control and intelligent learning, applied in rolling mill control device, rolling force/roll gap control, metal rolling, etc., can solve problems such as low efficiency, large uncertainty of artificial correction, false feedback of width control model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

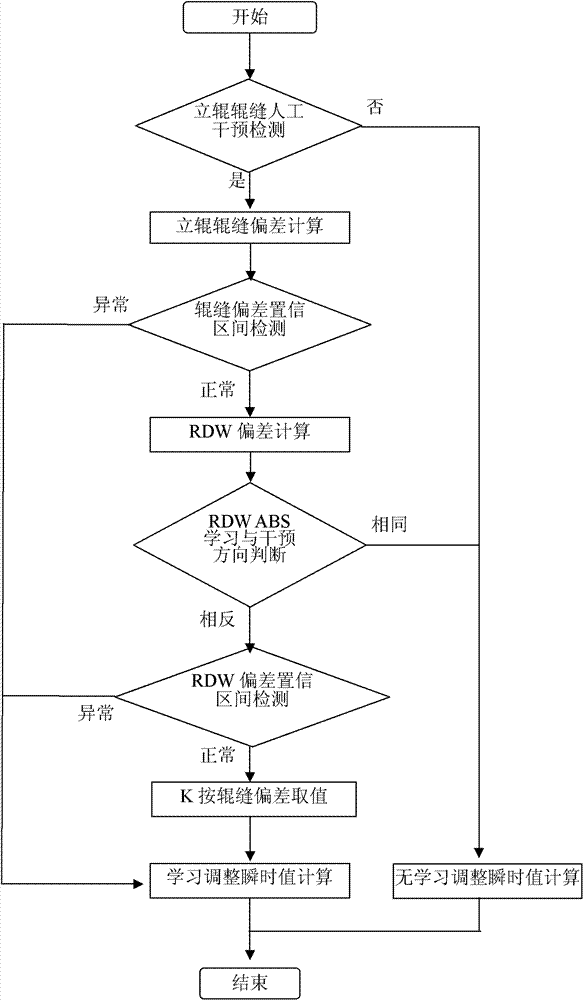

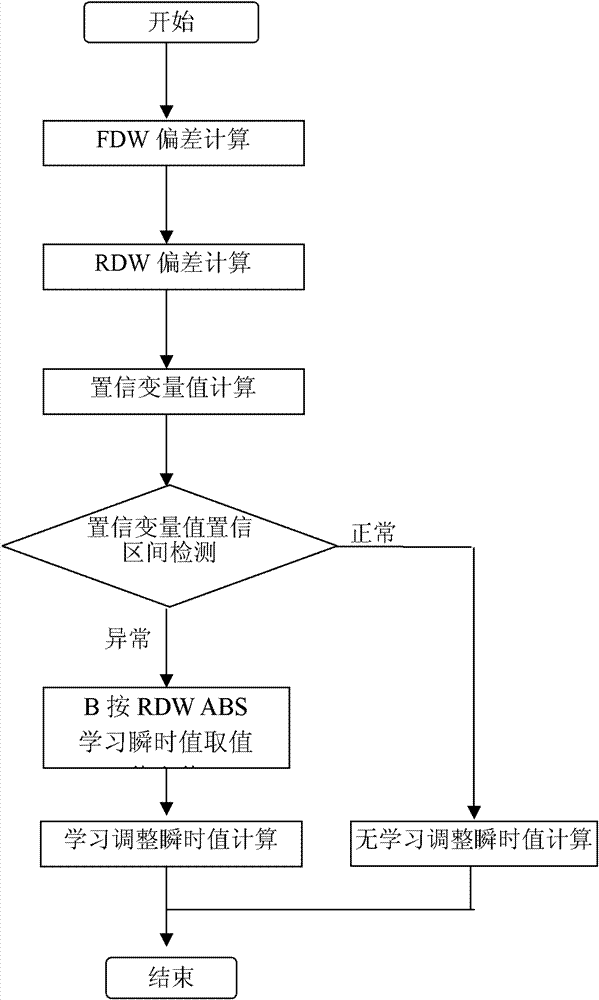

Method used

Image

Examples

Embodiment 1

[0103] The thickness of the finished strip is 2.75mm, the width of the finished strip is 1358mm, the number of rolling passes of the second rough rolling mill is 3, and the input value of the width margin screen is MGN HMI 0mm, RDW learning effect coefficient A is 0.8.

[0104] Table 1 Slab, strip width and control parameters

[0105] project

RDW(mm)

FDW(mm)

E2GAP1(mm)

E2GAP3(mm)

set width

1391.1

1373.6

1370.0

1378.6

feedback width

1389.8

1375.6

1369.9

1361.3

Deviation

-1.3

2.0

-0.1

-17.3

[0106] E2GAP1 is the roll gap of the vertical rolls in the first pass of the second roughing mill, and E2GAP3 is the roll gap of the vertical rolls in the third pass of the second roughing mill.

[0107] The above data shows that the operator adjusted the roll gap of the vertical rolls in the third pass of the second roughing mill inwardly by 17.3mm, and the over-w...

Embodiment 2

[0168]The thickness of the finished strip is 2.3mm, the width of the finished strip is 1053mm, the number of rolling passes of the second rough rolling mill is 3, and the input value of the width margin screen is MGN HMI 0mm, RDW learning effect coefficient A is 0.8.

[0169] Table 3 Parameters related to slab, strip steel and width control

[0170] project

RDW(mm)

FDW(mm)

E2GAP1(mm)

E2GAP3(mm)

set width

1076.0

1066.0

1041.5

1035.3

feedback width

1077.0

1081.0

1042.1

1043.3

Deviation

1.0

15.0

0.6

8.0

[0171] E2GAP1 is the roll gap of the vertical rolls in the first pass of the second roughing mill, and E2GAP3 is the roll gap of the vertical rolls in the third pass of the second roughing mill.

[0172] The above data shows that the operator manually adjusted the roll gap of the vertical rolls in the third pass of the second roughing mill by 8mm outw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com