Mobile anti-rust clogging cooling water tank

A technology for cooling water tanks and cooling water, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., to achieve the effects of prolonging continuous working time, improving filtering effect, and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

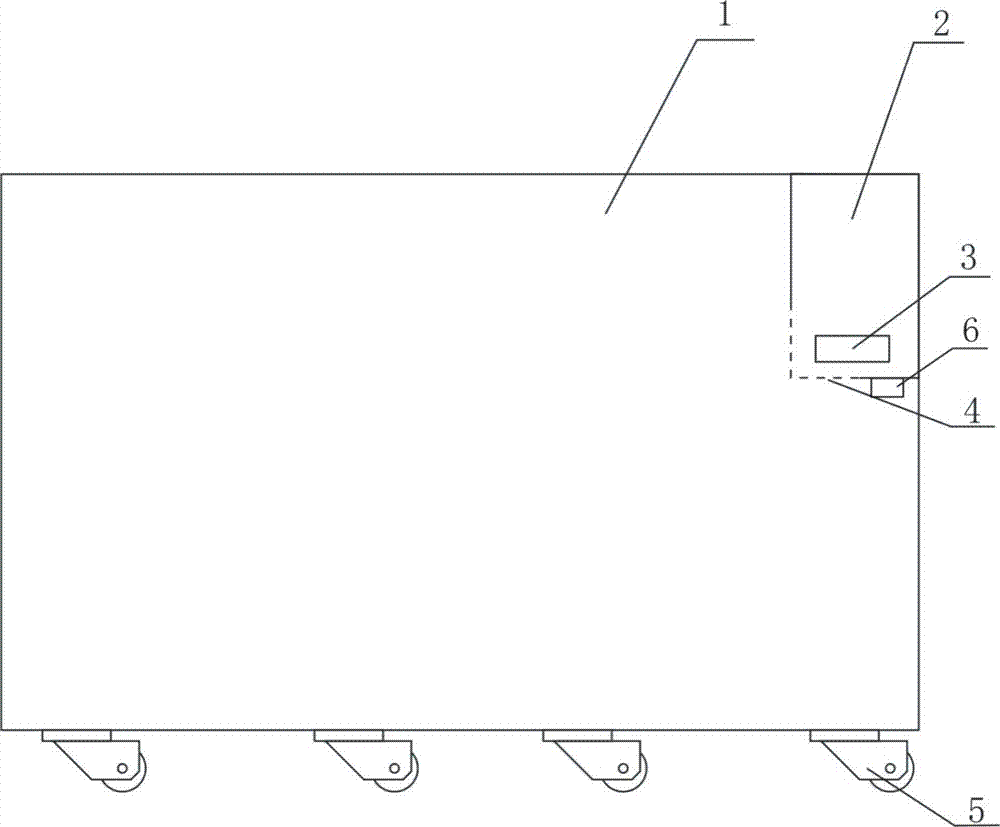

[0016] Such as figure 1 As shown, the movable anti-rust cooling water tank is provided with a filter box 2 in its box body 1, the inlet of the filter box 2 is connected with the cooling water return port of the box body 1, and the outlet of the filter box 2 Connected to the water storage cavity of the box body 1, the outlet of the filter box 2 is provided with a filter screen 4, and the wall of the filter box 2 is provided with a vibrator 6.

[0017] Since the processed workpieces are mostly made of steel and can be absorbed by magnets, in order to reduce the burden on the filter screen 4 and improve the filtering effect, the filter box 2 is provided with a permanent magnet 3 for absorbing debris.

[0018] Vibrator 6 can shake the metal shavings on the filter screen 4 away from the filter screen 4, like this: the one, avoid metal chips fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com