Aerobic three-phase separator and application method thereof in sewage treatment

A technology of a three-phase separator and an application method, which is applied in the field of reaction, separation and sedimentation devices, can solve problems such as energy consumption, reduction of biological activity, and unfavorable biodegradation reactions, so as to reduce floor space, improve processing efficiency, reduce investment and operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing:

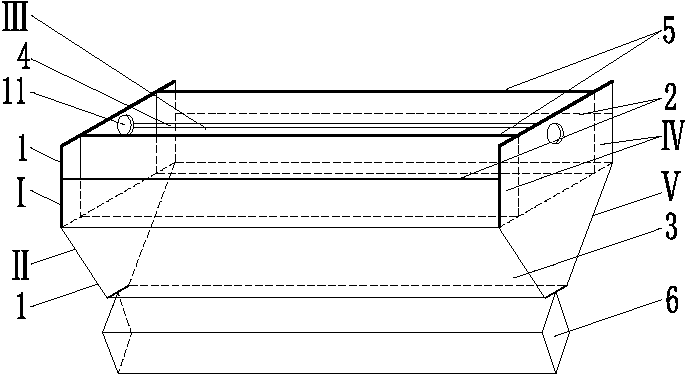

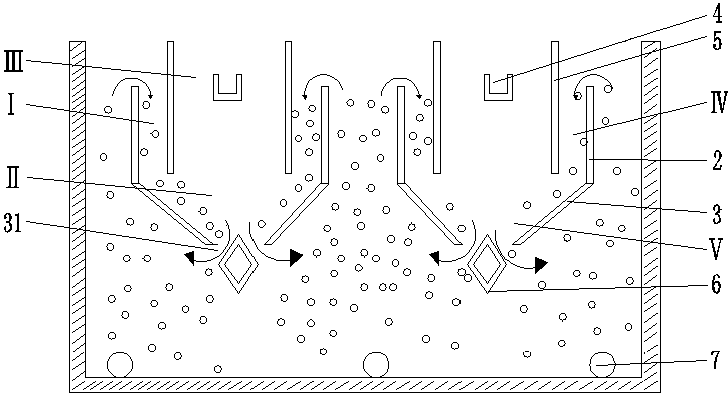

[0018] see figure 1 As shown, the aerobic three-phase separator is composed of two end plates 1 arranged in parallel, respectively connected vertically to the two sides of the two end plates 1 with a deflector 2 whose top is a rectangular cavity I, and the bottom of the second deflector 2 The ends are respectively folded inward and vertically connected with the two sides of the end plate 1 to form the inclined plate 3 of the bottom conical cavity II with the sludge return slot 31, and the two end plates 1 located on the horizontal axis of the top rectangular cavity I The overflow weir 4, the position corresponding to the overflow weir 4 of the two end plates 1 is provided with the outlet 11 connected with the overflow weir 4, the overflow weir 4 and the deflectors 2 on both sides of the overflow weir 4 The sedimentation partitions 5 suspended downward along the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com