Release paint for artificial leather and release paper prepared by utilizing release paint

An artificial leather and release coating technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of stiff texture, affecting the simulation effect, uneven distribution of pores on the surface of artificial leather, etc., to achieve high simulation effect and avoid a stiff feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In parts by weight, 30 parts of isodecyl acrylate, 5 parts of perfluoroalkyl ethyl methacrylate (ZonylTM), 20 parts of methoxypolyethylene glycol (350) monomethacrylate, 20 parts Tripropylene glycol diacrylate, 10 parts of trimethylolpropane triacrylate, 2 parts of fluorinated epoxy resin (see Chinese Patent CN 101497730A Example 1 for the preparation method), 4 parts of Irgacure 184, 5 parts of diethylenetriamine 1 part of resin sand with an average particle size of 50 microns. At room temperature, put the above-mentioned components into a container to mix, stir and disperse at a high speed, so as to promote the dissolution of the soluble solid components and obtain a uniform particle-containing component. Release coating.

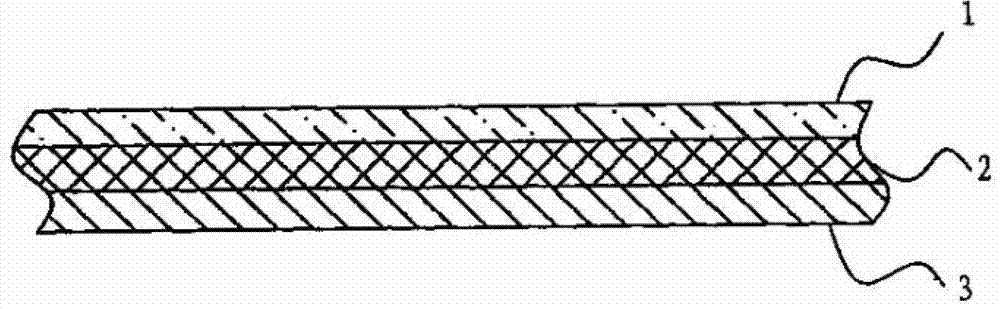

[0032] Such as figure 1 As shown, a release paper for artificial leather comprises a base paper 1, a base coat 2 and a release coat 3 on one side of the base paper 1 surface.

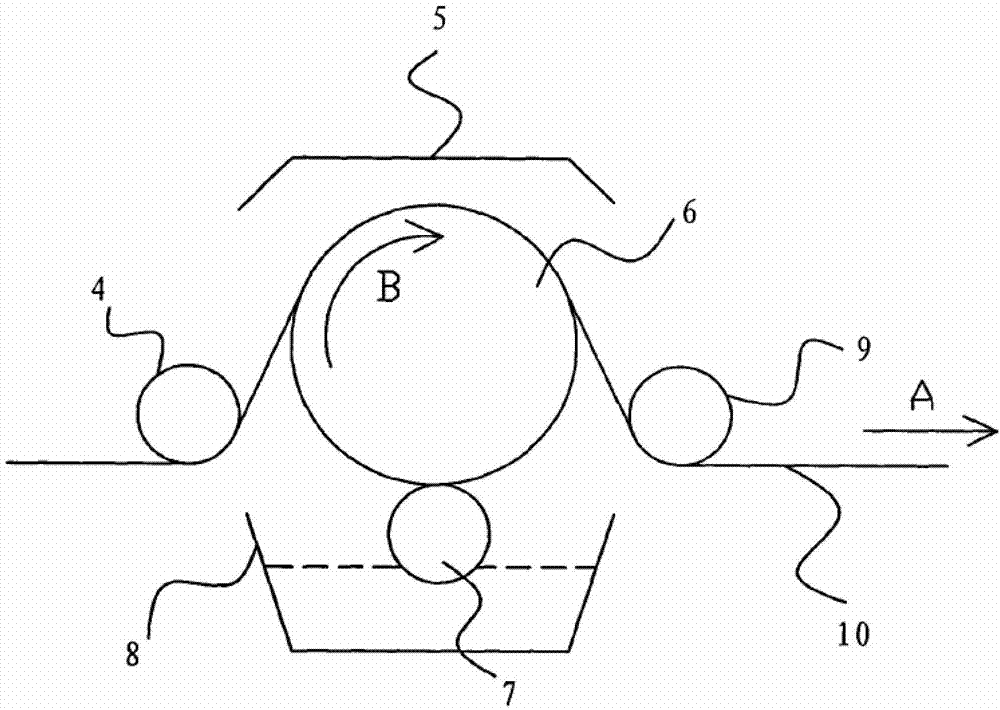

[0033] The basic requirements for base paper 1 in the present inventi...

Embodiment 2

[0037]In parts by weight, 30 parts of isodecyl acrylate, 5 parts of perfluoroalkyl ethyl methacrylate (ZonylTM), 20 parts of methoxypolyethylene glycol (350) monomethacrylate, 20 parts Tripropylene glycol diacrylate, 10 parts of trimethylolpropane triacrylate, 2 parts of fluorinated epoxy resin (see Chinese Patent CN 101497730A Example 1 for the preparation method), 4 parts of Irgacure 184, 5 parts of diethylenetriamine , 1.4 parts of resin sand with an average particle size of 70 microns. At room temperature, put the above-mentioned components into the container successively to mix, stir and disperse at a high speed, so that the solubilized solid components are dissolved, and a uniform particle component is obtained. Release coating.

[0038] According to the method described in Example 1, the release coating containing particle components was coated on the base coat 2 to obtain the release paper 10 .

Embodiment 3

[0040] In parts by weight, 30 parts of isodecyl acrylate, 5 parts of perfluoroalkyl ethyl methacrylate (ZonylTM), 20 parts of methoxypolyethylene glycol (350) monomethacrylate, 20 parts Tripropylene glycol diacrylate, 10 parts of trimethylolpropane triacrylate, 2 parts of fluorinated epoxy resin (see Chinese Patent CN 101497730A Example 1 for the preparation method), 4 parts of Irgacure 184, 5 parts of diethylenetriamine , 2 parts of resin sand with an average particle size of 100 microns, at room temperature, put the above-mentioned components into the container in turn, mix, stir and disperse at a high speed, so as to promote the dissolution of the solubilized solid components, and obtain a uniform particle-containing component Release coating.

[0041] According to the method described in Example 1, the release coating containing particle components was coated on the base coat 2 to obtain the release paper 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com