Preparation method for acrylate pressure sensitive adhesive providing good adhesion for low energy surface

An acrylic and surface bonding technology, which is applied in the field of preparation of acrylic pressure-sensitive adhesives, can solve problems such as poor storage performance, high cost, and slow curing speed of pressure-sensitive adhesives, so as to improve fluidity and production efficiency , Reduce the effect of inventory backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

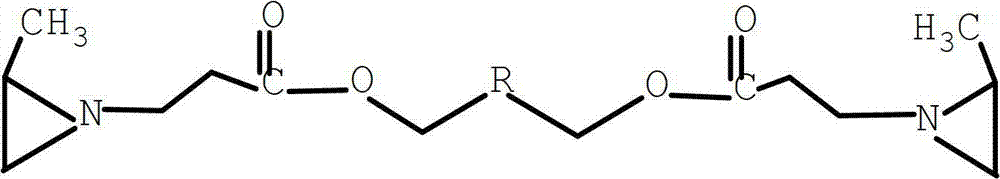

[0022] A method for preparing an acrylic pressure-sensitive adhesive good for bonding low-energy surfaces, mainly comprising the following steps:

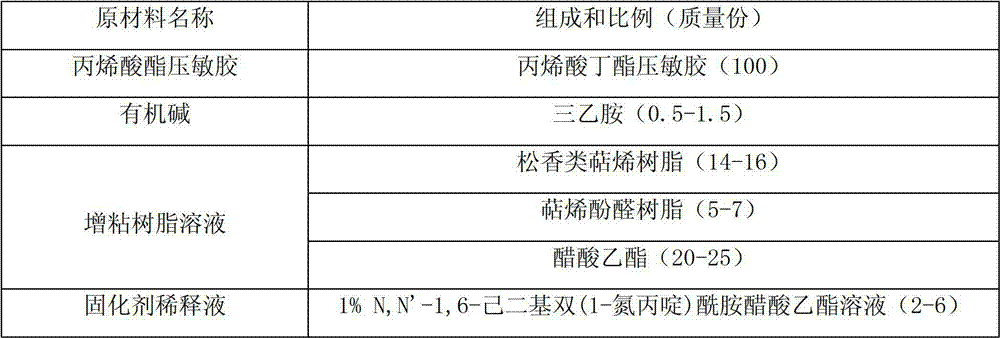

[0023] The formula that present embodiment adopts is:

[0024]

[0025] The preparation process and conditions of the present embodiment are as follows:

[0026] According to the composition and ratio of above-mentioned formula, carry out following steps:

[0027] (1) Add an organic base to the acrylate pressure-sensitive adhesive, stir well and let stand for 10 minutes to prepare a pressure-sensitive adhesive mixture;

[0028] (2) Add tackifying resin solution to the pressure-sensitive adhesive mixture prepared in step (1), stir well and let stand for 10 minutes;

[0029] (3) Add an appropriate amount of curing agent diluent to the pressure-sensitive adhesive mixture prepared in step (2), stir well and let stand for 20 minutes;

[0030] (4) Apply the pressure-sensitive adhesive prepared in step (3) evenly on the substrate, a...

Embodiment 2- Embodiment 10

[0033] The same process steps as in Example 1 were used to prepare an acrylic pressure-sensitive adhesive with good adhesion to low-energy surfaces, and the corresponding performance tests were carried out. The difference is that the formulation compositions and ratios listed in Table 1 were used respectively. The performance test results of the prepared acrylic pressure-sensitive adhesive with good adhesion to low-energy surfaces are also marked in Table 1; where qualified means that the prepared product has been completely cured within 0.5h-1h, and there is no post-curing Effect, 180° peel strength ≥ 20N / 20mm, room temperature holding power ≥ 35h, it still has fluidity and can be used in the coating process of pressure-sensitive adhesive products after being stored for 8-12 days under sealed and dark conditions at room temperature.

[0034] Table 1

[0035]

[0036]

[0037] As can be seen from Table 1, the acrylic pressure-sensitive adhesive with good adhesion to low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com