Anti-overfilling urea box

A technology of urea tank and filling port, which is applied in the field of urea tank, can solve the problems of urea tank swelling, bursting, expansion volume is not enough to store crystallized urea, etc., and achieve the effect of preventing swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

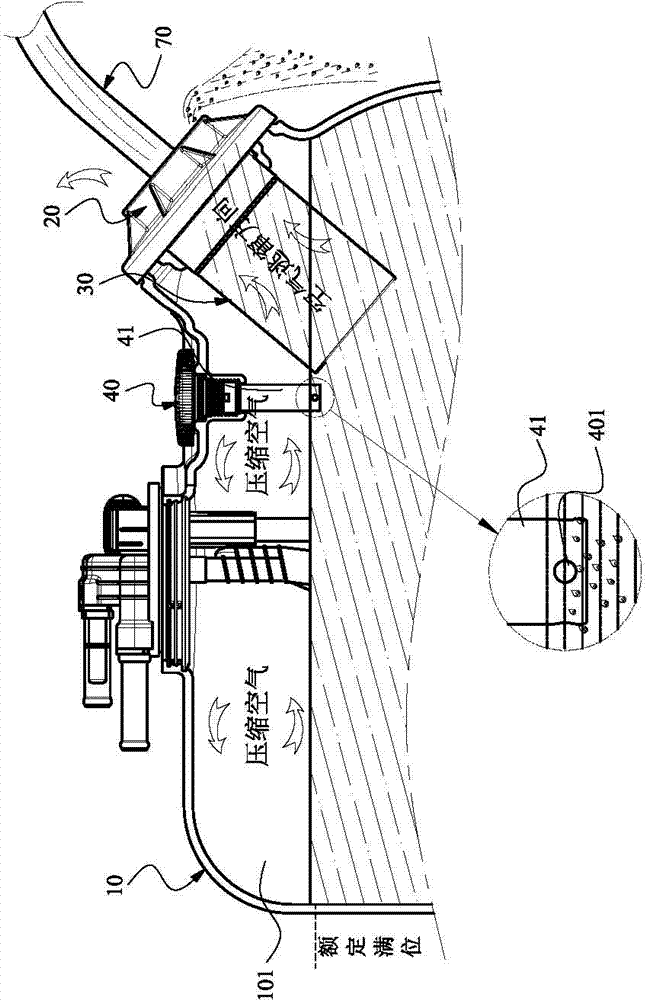

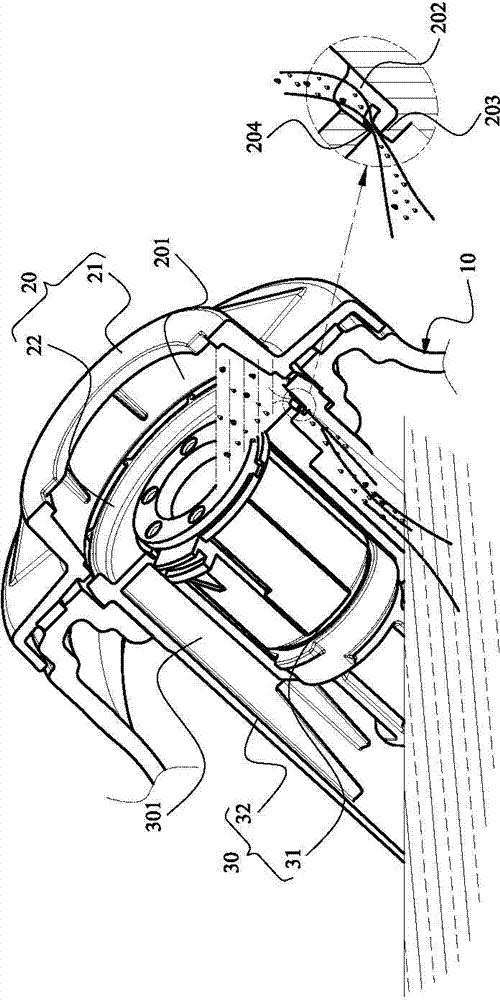

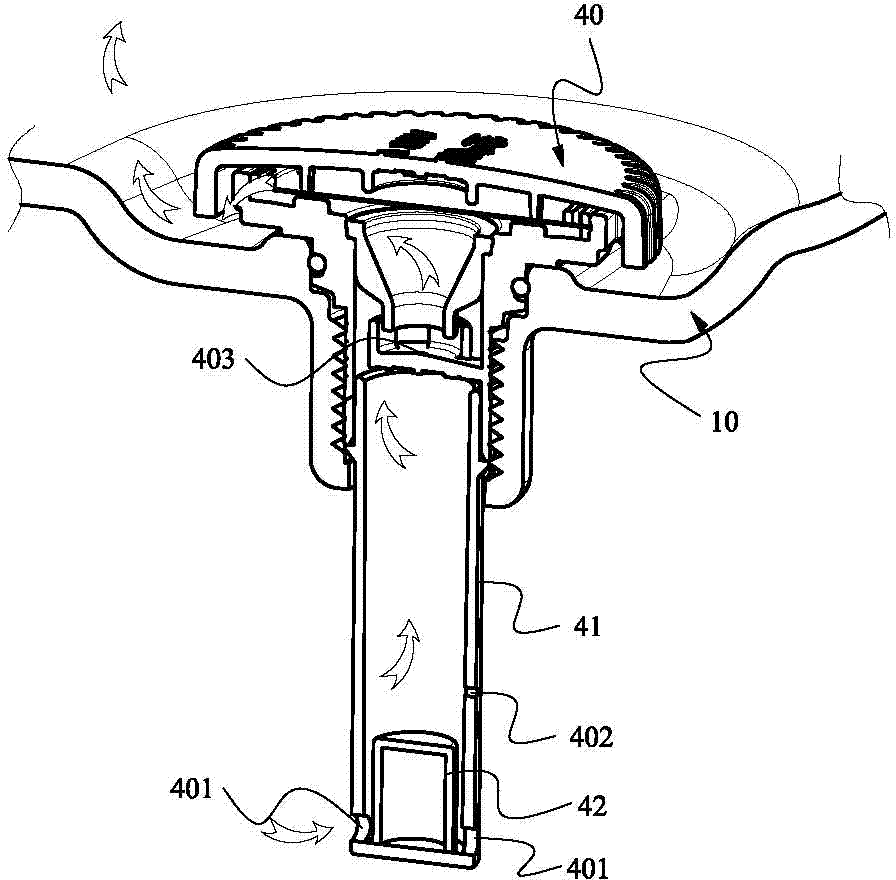

[0045] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the box body 10 .

[0046]The box body 10 has a rated full level, and an expansion space 101 for the expansion of the urea solution is formed between the rated full level and the top of the box body 10; the top of the box body 10 is provided with a filling port 20, and the filling port 20 extends a filling cylinder 30 that extends into the inside of the box body 10, and the highest position of the output port of the filling cylinder 30 is at the same level as the rated full level of the box body 10; specifically, in this embodiment , the filling port 20 includes an upper cover 21 and a lower cover 22 arranged on the box body 10; the upper cover 21 is fixed on the box body 10 by welding; the lower cover 22 is loaded by an interference fit And fixed on the box body 10, the filling tube 30 integrally extends from the lower cover 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com