Engine manual start assembly and engine thereof

An engine and manual technology, which is applied to the starting of the engine, engine components, machines/engines, etc., can solve the problems of the complex structure of the manual starting assembly, the deviation of the edge alignment of the driving cam, and the influence of the normal operation of the manual starting, etc. Achieve compact structure, improve reliability, and avoid jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

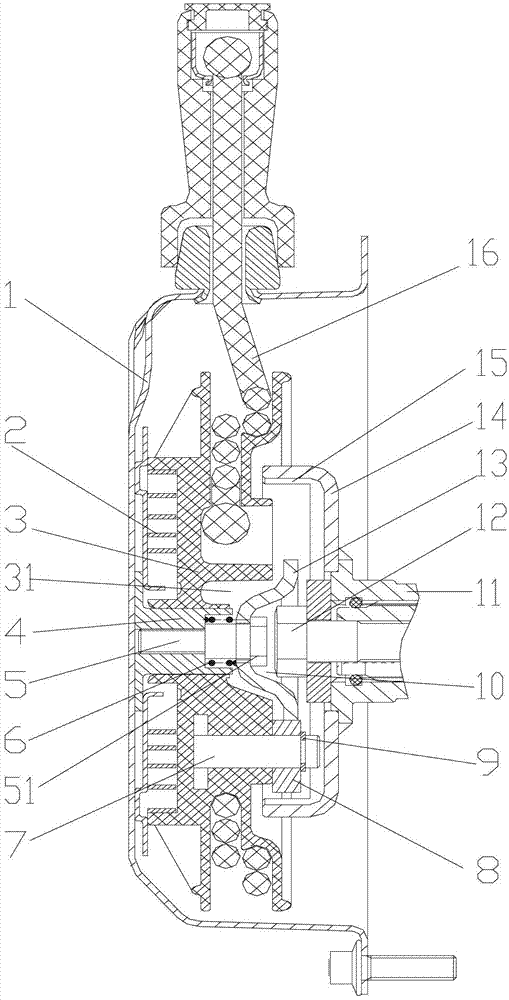

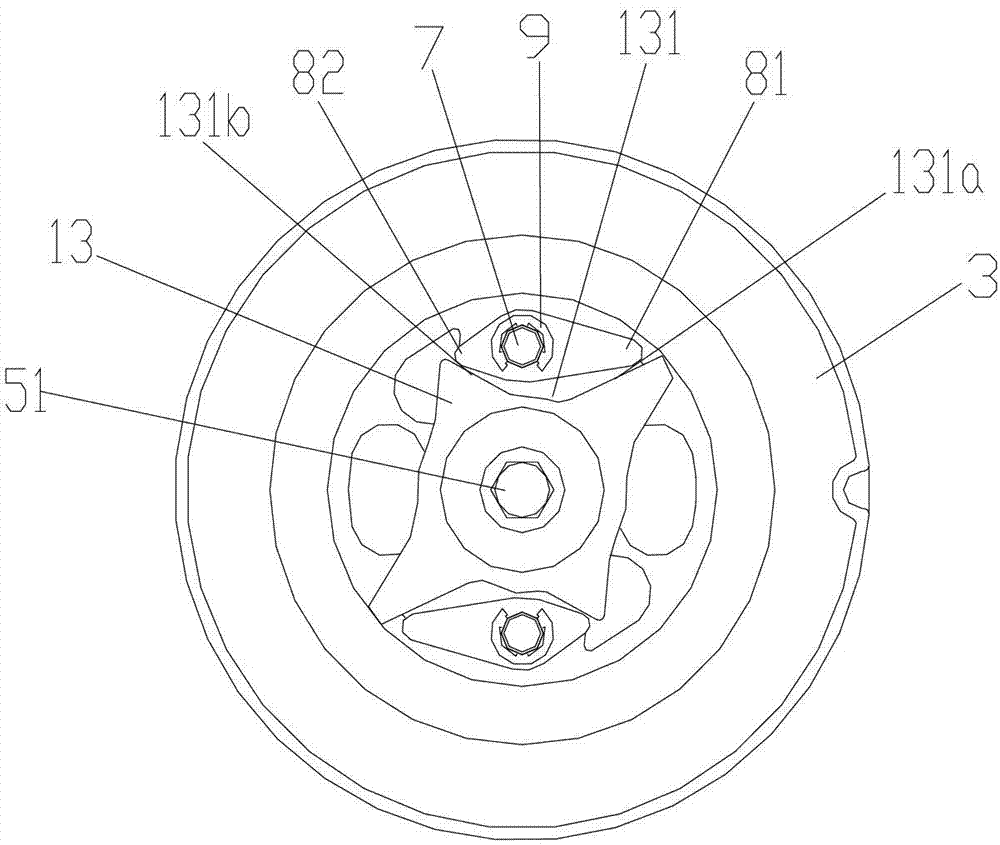

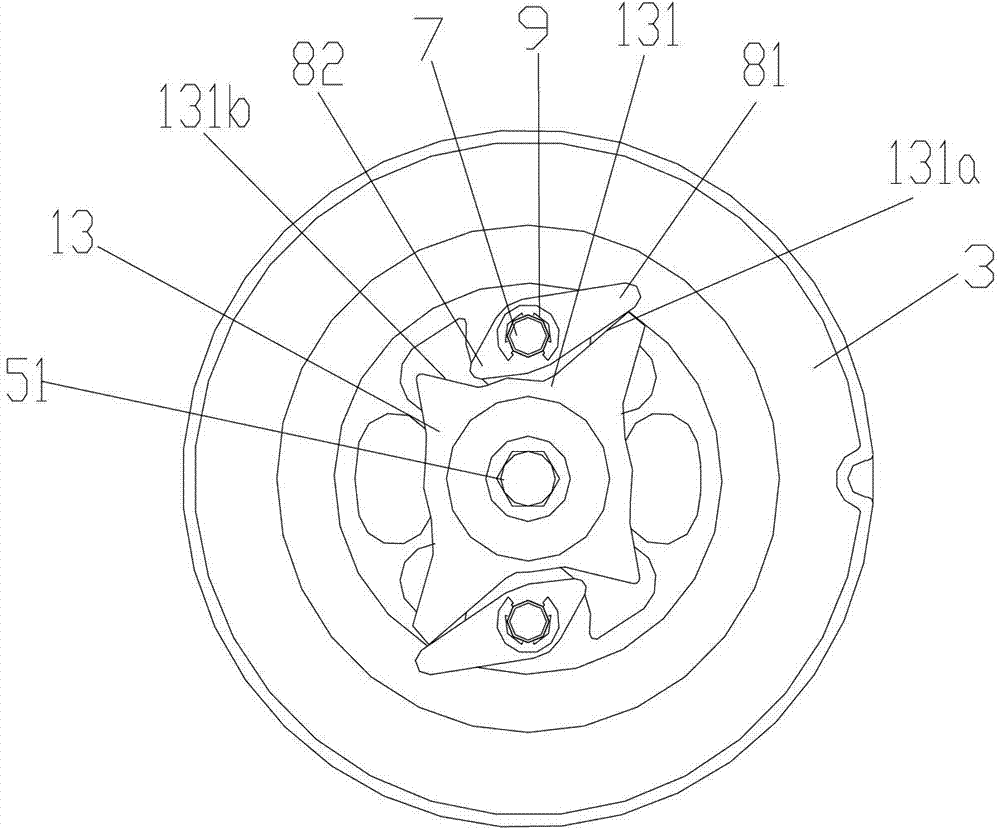

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the free state structure of the present invention, image 3 It is a structural schematic view of the working state of the present invention, as shown in the figure: the engine pull-start assembly of the present embodiment includes a housing 1, a starting connecting sleeve 14 and a pull cord assembly for driving the starting connecting sleeve 14 to rotate, such as As shown in the figure, the casing 1 is fixedly connected with the engine casing; the starting connecting sleeve 15 is in transmission cooperation with the engine crankshaft 11, and the cable pulley assembly includes a pulley pulley 3, a pulley pulley return torsion spring 2, a drive cam 8 and The guide plate 13, the pull rope reel 3 and the guide plate 13 are located coaxially in the housing 1 and are arranged in the housing 1 in cooperation with their respective rotations. The pull rope reel 3 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com