Plate-type evaporator

A plate-type evaporator and evaporation zone technology, which is applied to evaporators/condensers, refrigeration components, refrigerators, etc., can solve the problems of low heat exchange efficiency and large space occupied by the evaporator, and achieve improved heat exchange efficiency and compact structure , the effect of low footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following embodiments will be used to further illustrate the present invention in conjunction with the drawings.

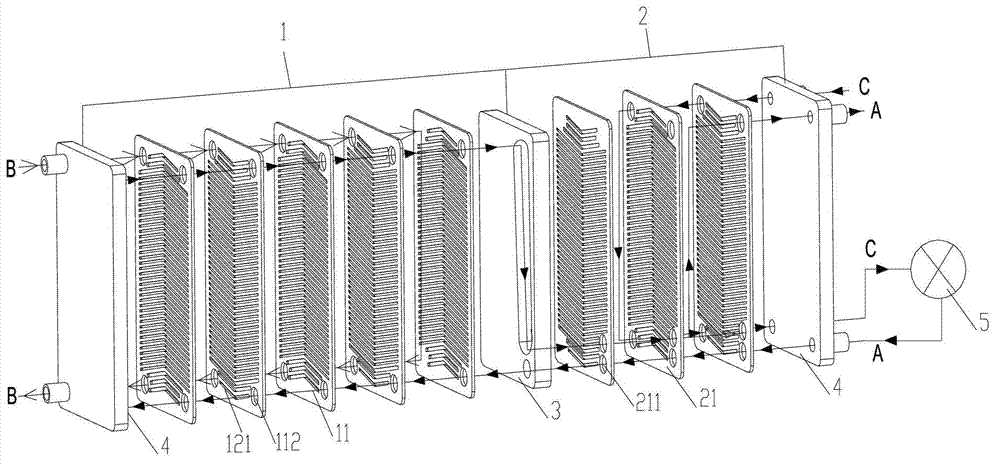

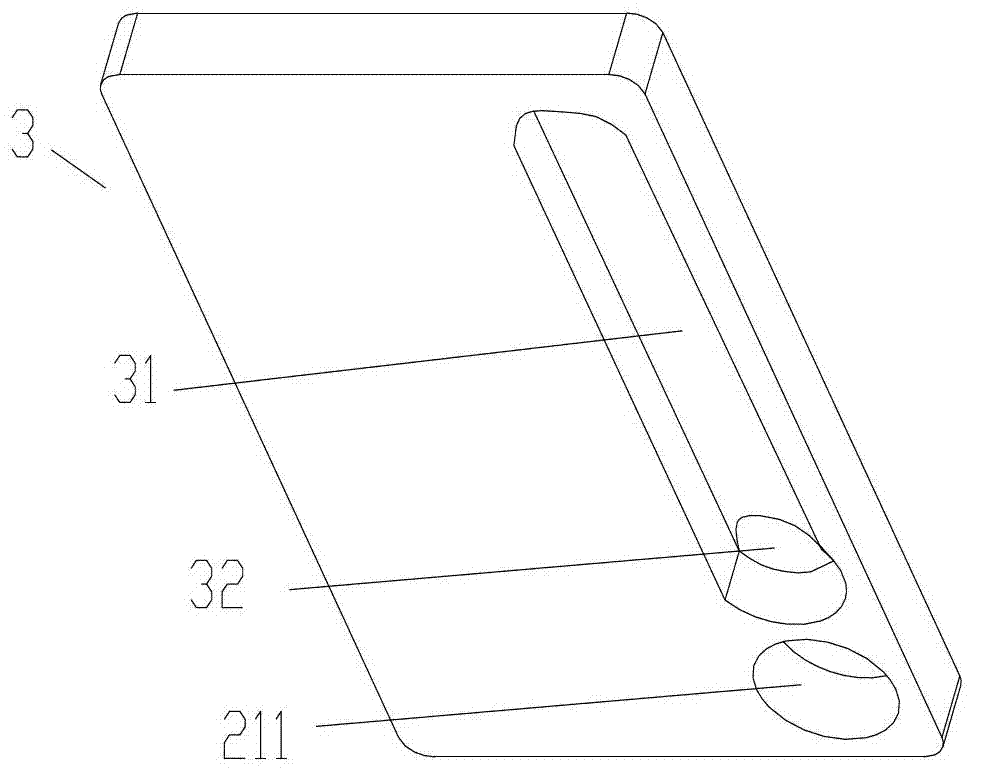

[0025] figure 1 , figure 2 It is the plate condenser of the present invention. The plate evaporator includes an evaporation zone 1, which is formed by a plurality of evaporative heat exchange fins 11 closely connected to realize the heat exchange between the refrigerating medium A and the refrigerating liquid B; overheating zone 2, the overheating zone 2 It is formed by closely connecting a plurality of overheating heat exchange fins 21, which are used to realize the heat exchange between the refrigerant A after passing through the evaporation zone 1 and the hot fluid C after passing through the condenser; the evaporation zone 1 and the overheating zone 2 is separated by a baffle 3, the baffle 3 is provided with a guide groove 31 for guiding the refrigerating medium A heated in the evaporation zone 1 to the overheating zone 2. The cross-sectional area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com