Method for improving calibration precision of infrared sensor

An infrared sensor and calibration accuracy technology, which is applied in the infrared field to achieve the effects of improving calibration accuracy, improving temperature measurement accuracy, and overcoming large calibration errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

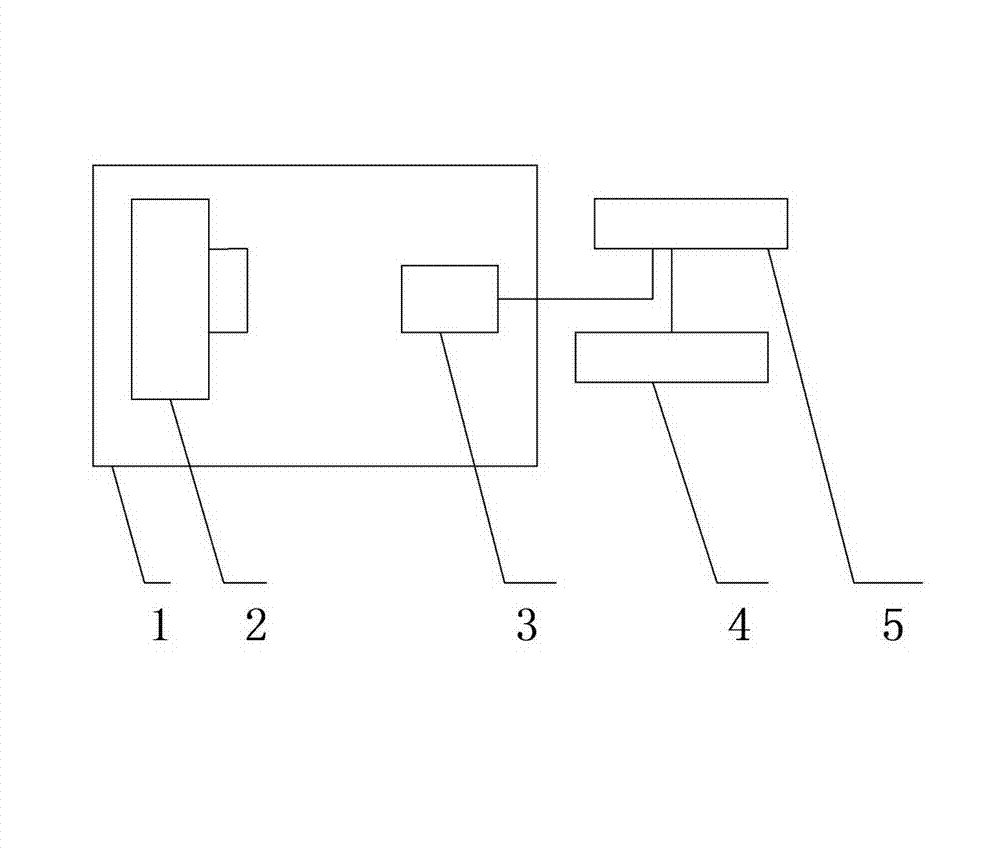

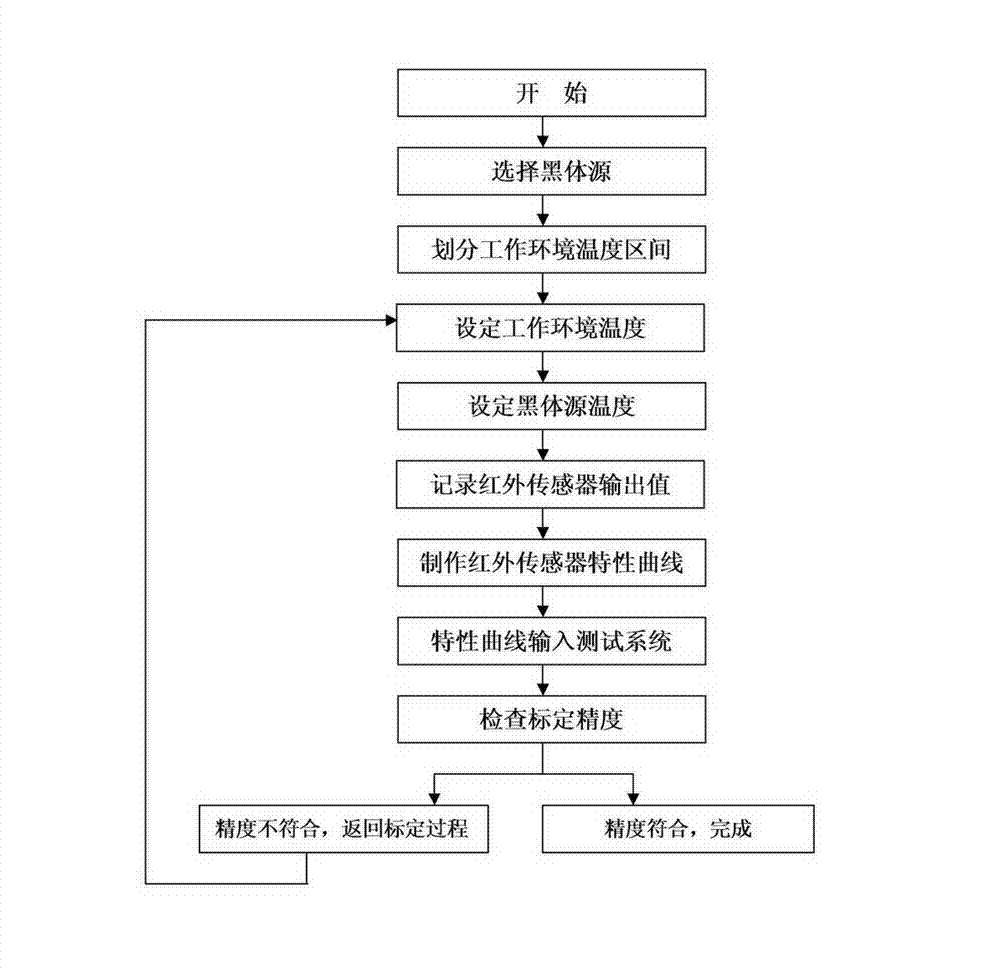

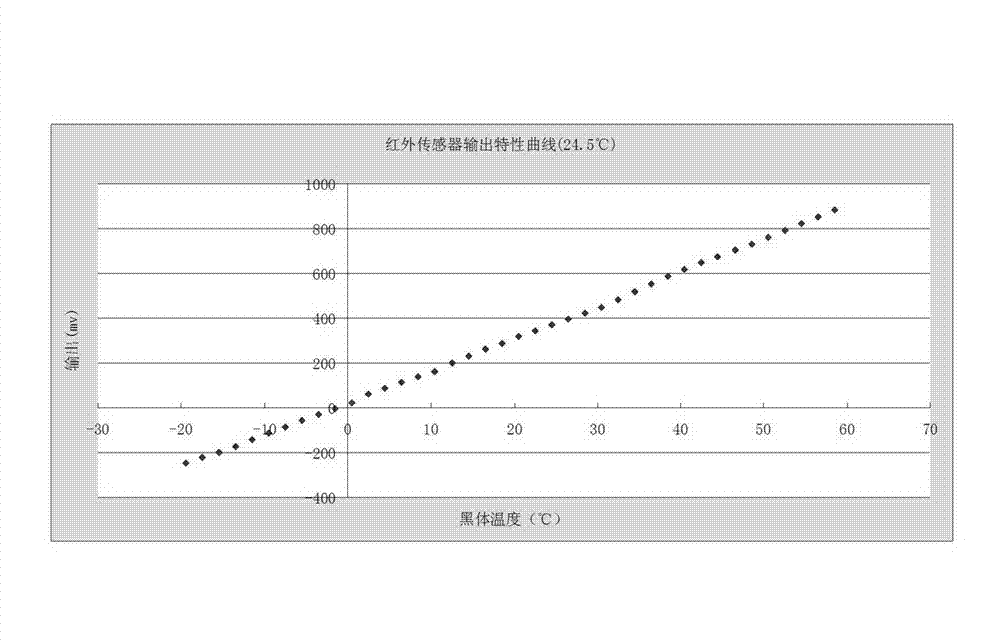

[0030] See attached figure 1 , figure 2 , the implementation of the present invention takes the example of an infrared sensor with an output of -2000 to 2000mv on a cement concrete pavement with a temperature measurement range of -20 to 60°C and an ambient temperature of -20 to 50°C. Including the following steps:

[0031] Step 1: Through the query data, the cement concrete emissivity coefficient is 0.95, select the HFY-302C low-temperature type with emissivity coefficient of 0.95, accuracy ±0.15% (full scale), temperature resolution: 0.01°C, and temperature range: -20~70°C blackbody source.

[0032] Step 2: According to the ambient temperature range of -20-50°C used for infrared sensor temperature measurement, divide 7 ambient temperature intervals at intervals of 10°C (see Table 1), select the bit value of each interval as a representative, and select the appropriate The ambient temperature test chamber sets the working environment temperature respectively.

[0033] Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com