High-accuracy static extra high pressure sensor and pressure measurement method

An ultra-high pressure, high-precision technology, applied in the field of static ultra-high pressure sensors, can solve the problems of low precision, bulky, limited use, etc., and achieve the effects of rapid response, small size, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

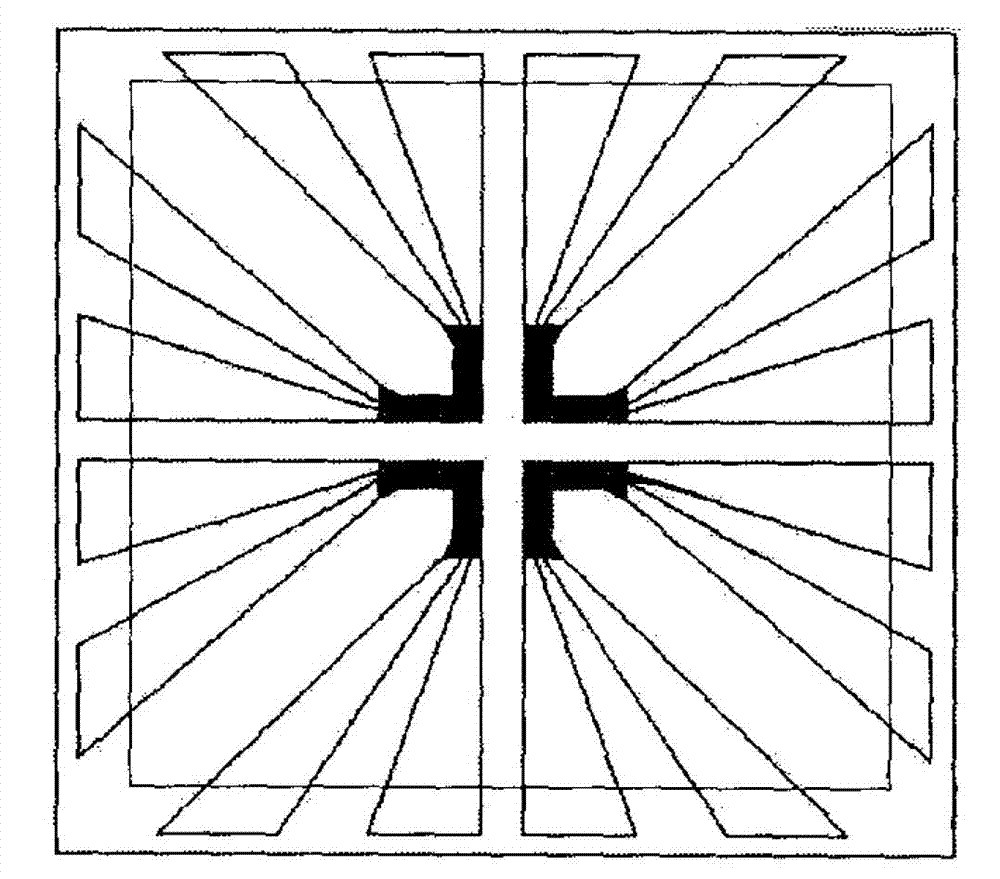

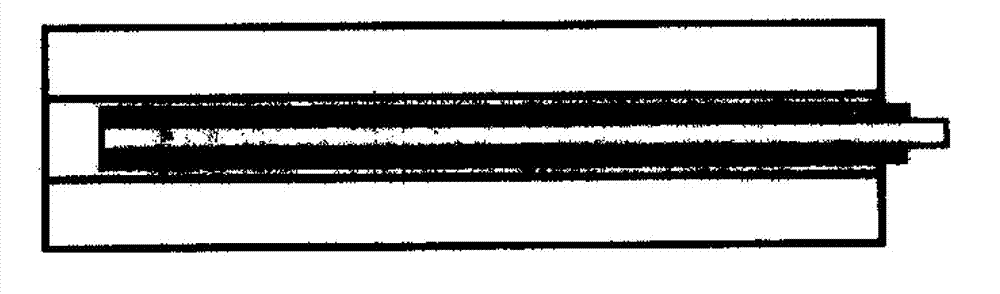

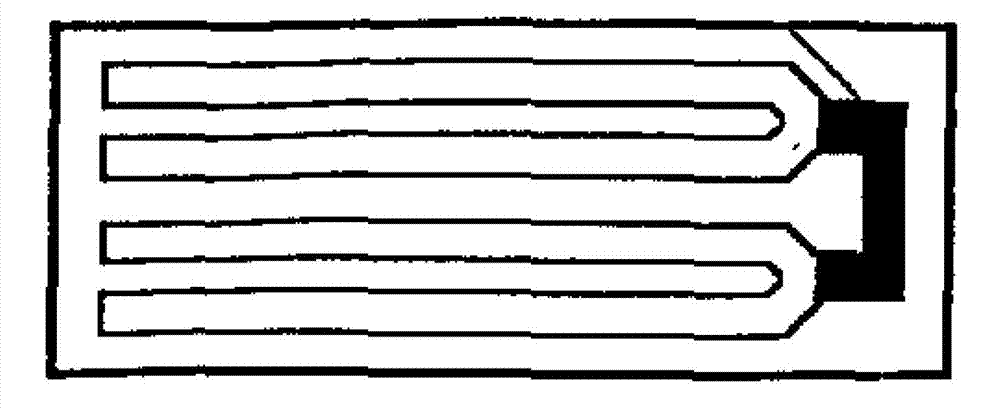

[0031] A high-precision static ultra-high pressure sensor, as attached Figure 5 As shown, the sensor housing 1 is included, and the sensor housing 1 is hermetically closed by the housing cover 2. The housing is an inner cavity 3 resistant to ultra-high pressure, and the inner cavity 3 is provided with a sensing element 4 and a sensor from the sensor. A lead base 5 for drawing electrical signals from the element 4, the sensing element 4 includes a sealed chamber 8 filled with a sensing medium for sensing pressure, and there is a sensing member 6 in the sealed chamber 8, and the sensing member is A rod member wound with a sensing wire, the sensing wire leads out an electrical signal through two lead cones 7 arranged in the lead base 5, and the two lead cones 7 are respectively connected with lead wires, and the lead base 5 is closed The sensing mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com