Grinder information network and energy monitoring system

A monitoring system, energy technology, applied in the direction of digital control, electrical program control, etc., can solve the problem of energy-saving potential analysis and calculation of the overall equipment energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

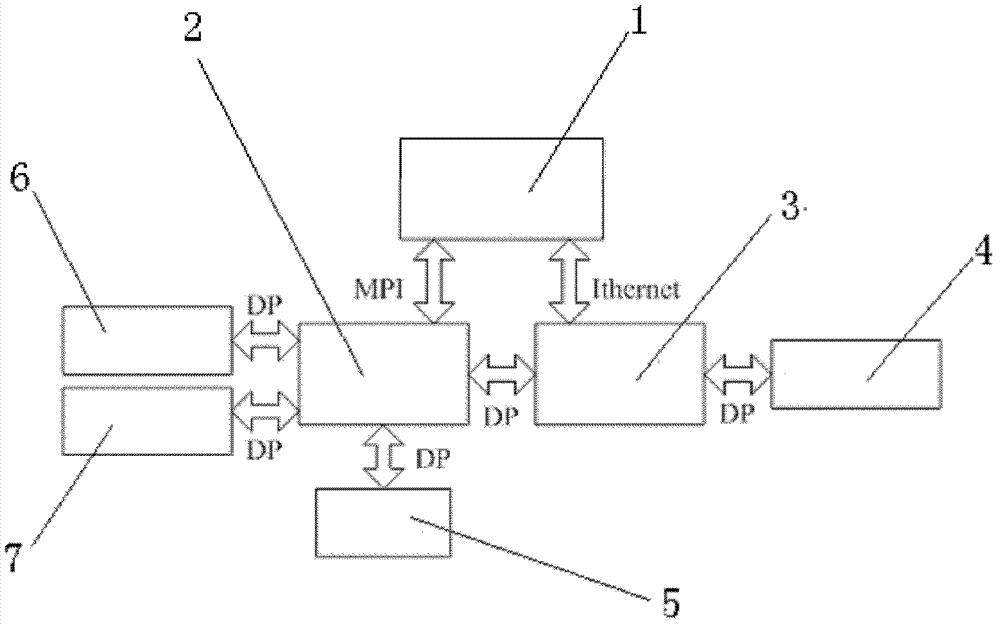

[0010] Such as figure 1 Shown, the present invention comprises PLC2, motion controller 3, frequency converter, servo driver 4, man-machine interface HMI (Human Machine Interface) 1, electric energy meter 5; The information of described frequency converter passes PROFIBUS-DP (Profibus Decentralized Periphery) The bus is transmitted to PLC2 and stored in the corresponding address, and the information of the state of the servo drive 4 is transmitted to the motion controller 3 through the PROFIBUS-DP (Profibus Decentralized Periphery) bus and passed through the motion controller 3 with the help of PROFIBUS-DP (Profibus Decentralized Periphery) The bus is sent to PLC2 and stored in the corresponding address; the energy data measured by the electric energy meter 5 is sent to PLC2 through the PROFIBUS-DP (Profibus Decentralized Periphery) bus; Send the data to the man-machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com