High-speed motor end cover type sliding bearing assembly method

A sliding bearing, high-speed motor technology, applied in electromechanical devices, electric components, manufacturing of motor generators, etc., can solve the problems of large vibration, burning tiles, and high bearing temperature, reducing vibration, reducing possibility, and increasing contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

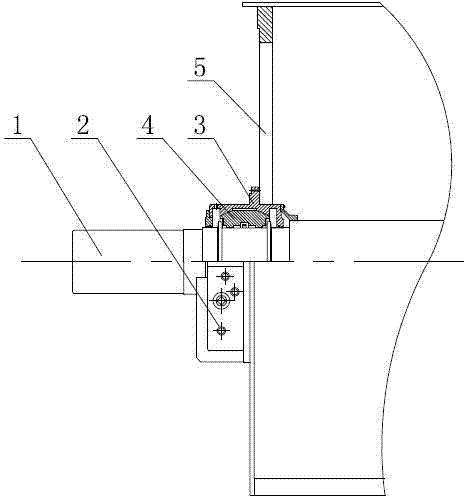

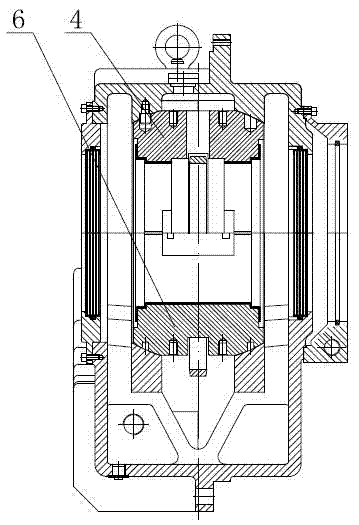

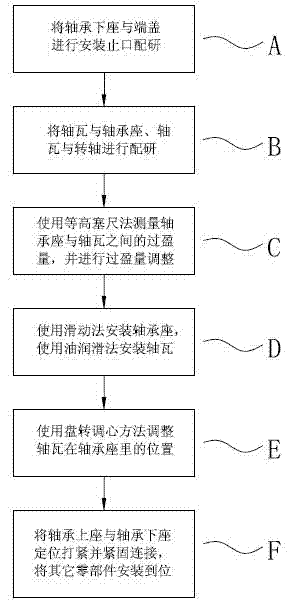

[0022] image 3 It is a flow chart of the assembly method of the present invention, combined with figure 1 , figure 2 The installation structure of the motor end cover type sliding bearing shown, that is, the motor end cover type sliding bearing is a split structure, the bearing seat of the sliding bearing includes a bearing upper seat 3 and a bearing lower seat 2, and the bearing shell of the sliding bearing Including the bearing pad 4 and the bearing pad 6, the assembly method of the present invention includes the following steps:

[0023] A. The bearing lower seat 2 and the end cover 5 are installed and matched with each other;

[0024] B. Matching and researching the upper bearing bush 4 with the bearing upper seat 3 and the rotating shaft 1, and matching the lower bearing bush 6 with the bearing lower seat 2 and the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com