Precision control of web material having micro-replicated lens array

A technology of micro-replication, web, applied in the field of web manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

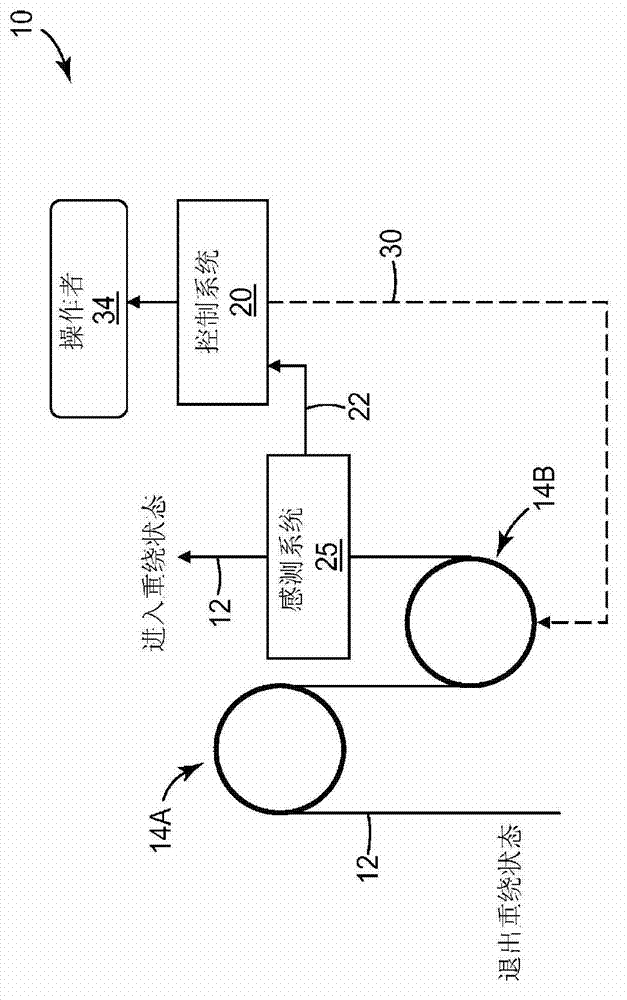

[0028] figure 1 is a block diagram illustrating a portion of a web-based manufacturing system 10 operating in accordance with the principles of the present invention. In this particular example, a section of a web transfer system is shown, including a plurality of driven and idler rollers, moving a web 12 through the web transfer system.

[0029] In this example, the web-based manufacturing system 10 includes two microreplication tools 14A, 14B (collectively "tools 14"), one following the other. The microreplication tool produces a web 12 with microstructures that may, for example, extend continuously in the machine direction of the web, or may form other two-dimensional (2D) patterns that simply repeat as the tool rotates . Such configurations may be used, for example, in the manufacture of web 12 to include microreplicated structures having micron-scale dimensions.

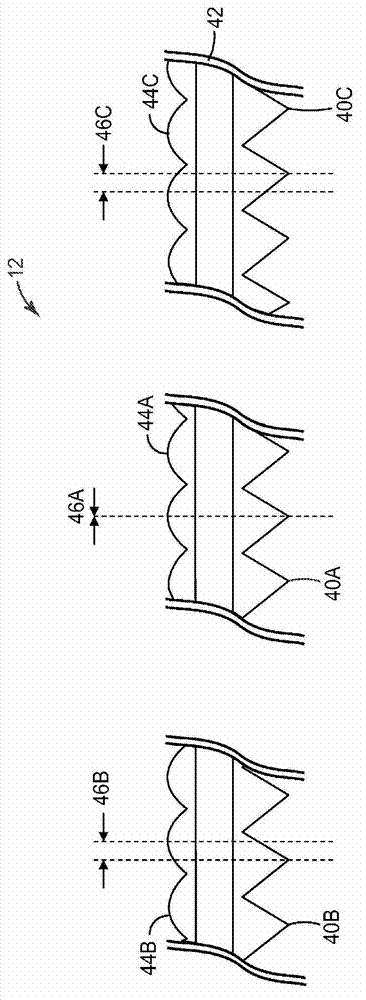

[0030] In one example, web 12 is formed as a two-layer film with opposing microstructure patterns on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com