Vertical shaft furnace, ferro-coke production facility, and method for producing ferro-coke

A technology for manufacturing vertical shaft furnaces and equipment, which is applied to vertical furnaces, coke ovens with vertical carbonization chambers, and shaft furnaces. Reduced use of energy, effects of equipment and operational simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

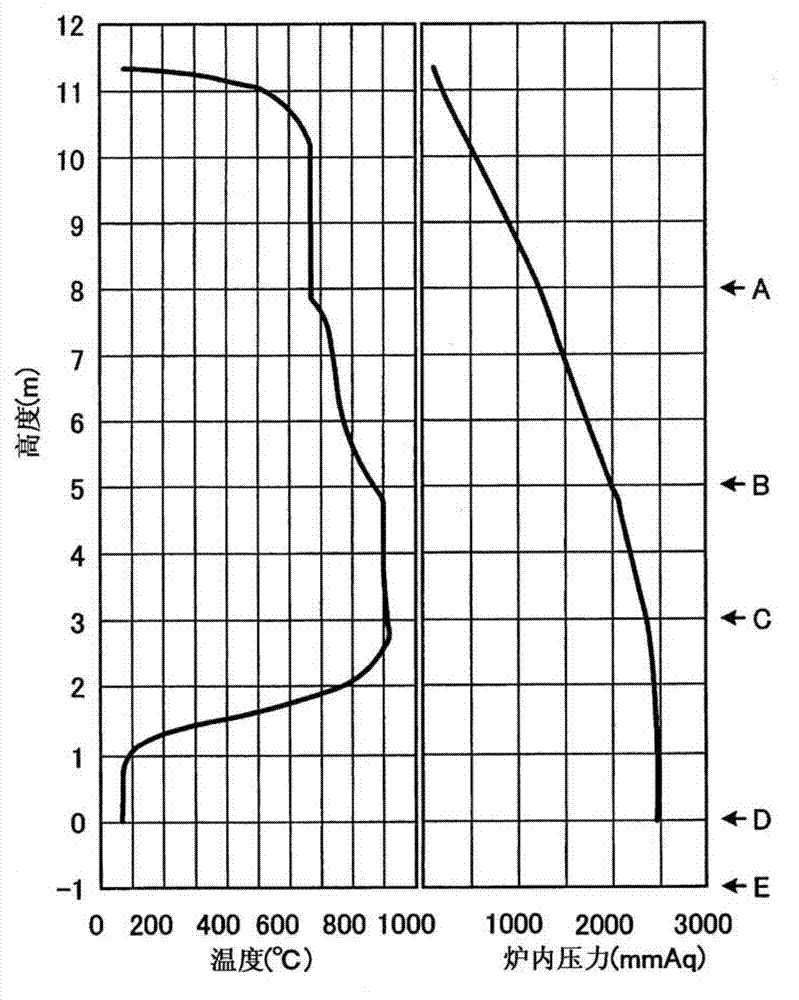

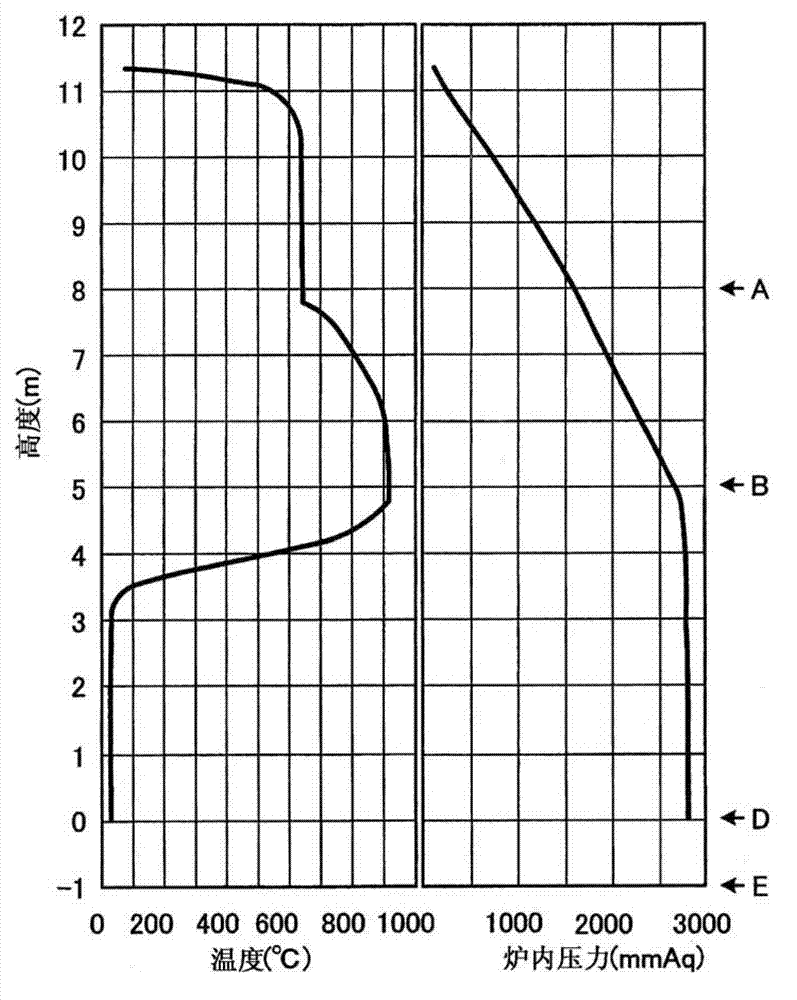

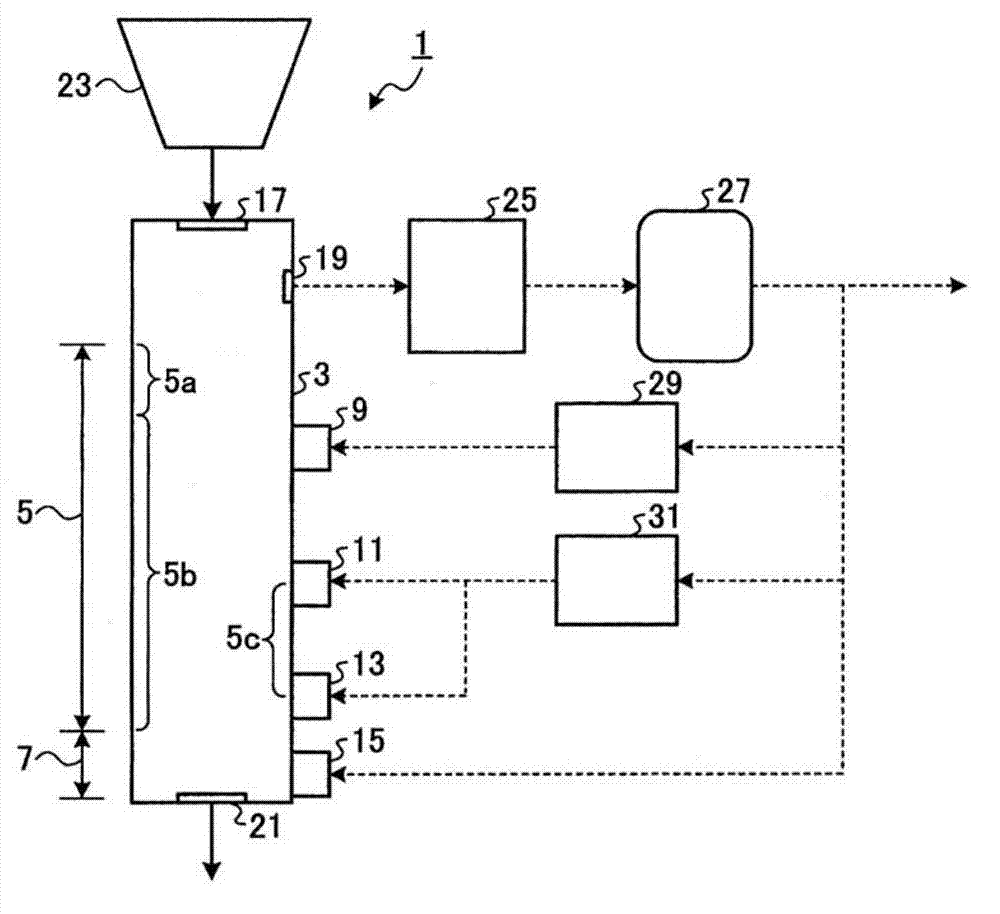

[0067] To confirm the effect of the present invention, use Figure 4 In the illustrated iron coke manufacturing test device, the high-temperature gas blowing tuyere is two-stage and one-stage, and the iron coke manufacturing test is carried out. Figure 4 neutralize figure 1 The same parts are marked with the same symbols. for Figure 4 The vertical shaft furnace 1 shown has a total length of 13.0m. It is set to 0.65m from the upper end of the furnace to the horizontal line of the feed line, and 3.5m from the horizontal line of the feed line to the center of the low-temperature gas blowing tuyere 9 , Set the center of the low temperature gas blowing into the tuyere 9 to the center of the high temperature gas blowing tuyere 11 in the upper section to 3.0m, from the center of the high temperature gas blowing into the tuyere 11 to the center of the high temperature gas blowing into the tuyere 13 in the lower section The center of the lower high-temperature gas blowing tuyere 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com