Rotary roll synchronizer for levelling machine

A synchronizer and skin pass mill technology, which is applied to the driving device of metal rolling mill, metal rolling, manufacturing tools, etc. The effect of improving rolling precision and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

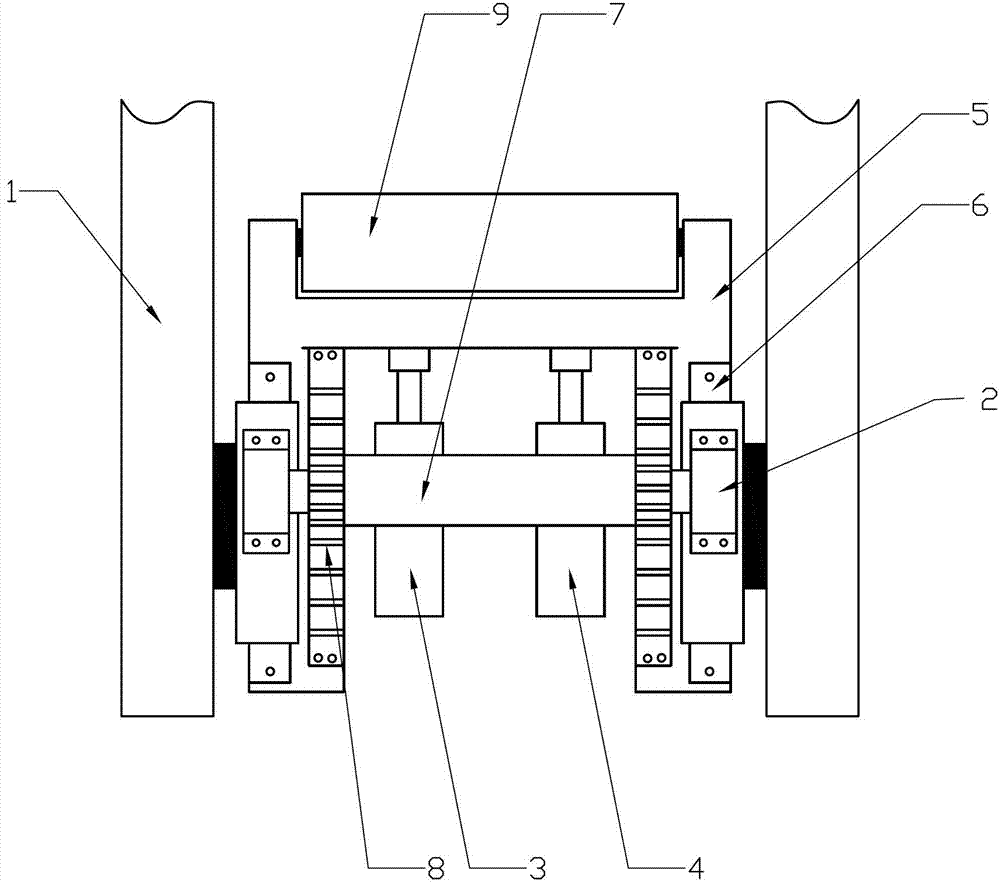

[0012] Such as figure 1 As shown, a roll synchronizer for a tempering machine includes a frame 1, a static part, a moving part and work rolls.

[0013] The static part includes a pair of bearing housings 2 fixed on the frame and synchronous rollers 7 installed in the bearing housings at both ends. Since the two ends of the synchronous rollers are fitted with bearings, the synchronous rollers can rotate freely.

[0014] The moving part comprises a flat plate 5, and the flat plate is a gate shape. Both sides of the flat plate 5 are slidably installed on the frame through the linear guide rail 6. The linear guide rail is composed of a chute and a slider. The specific style belongs to the existing mature technology, and the specification and model can be selected according to actual needs. A pair of oil cylinders are arranged between the frame and the plate, marked as the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com