Injection molding mold of container plastic part and injection molding method thereof

A technology for injection molds and plastic parts, applied in household appliances, other household appliances, hollow objects, etc., can solve the problems of workpiece deformation, difficult to grasp the timing of demolding, low injection production efficiency, etc., to avoid product deformation or damage, shortening The time required for demolding and the effect of improving the efficiency of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

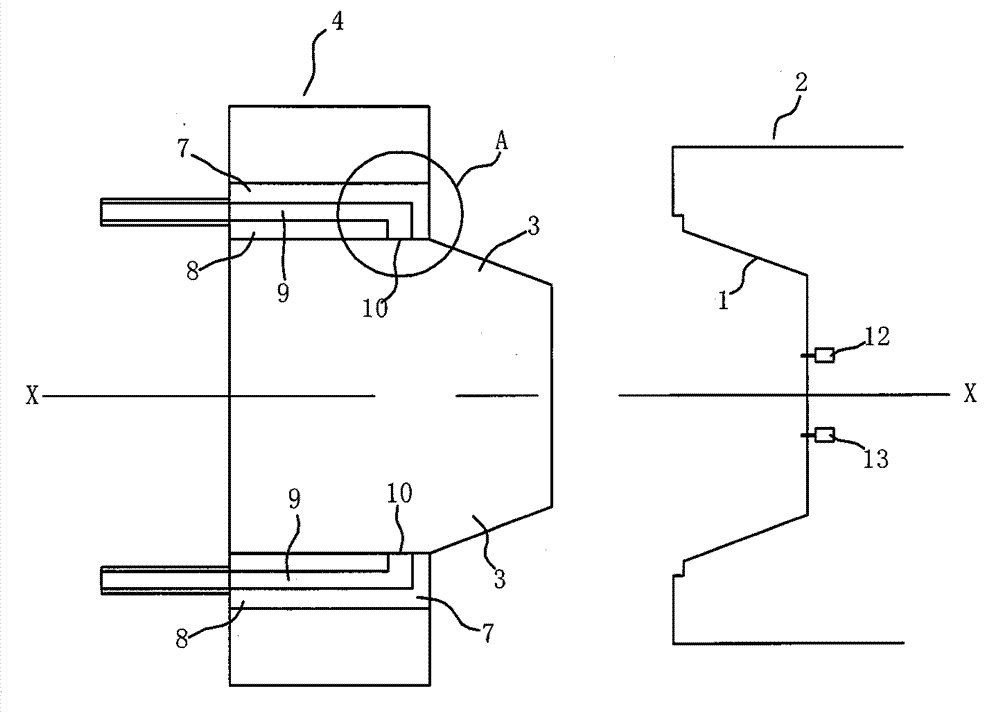

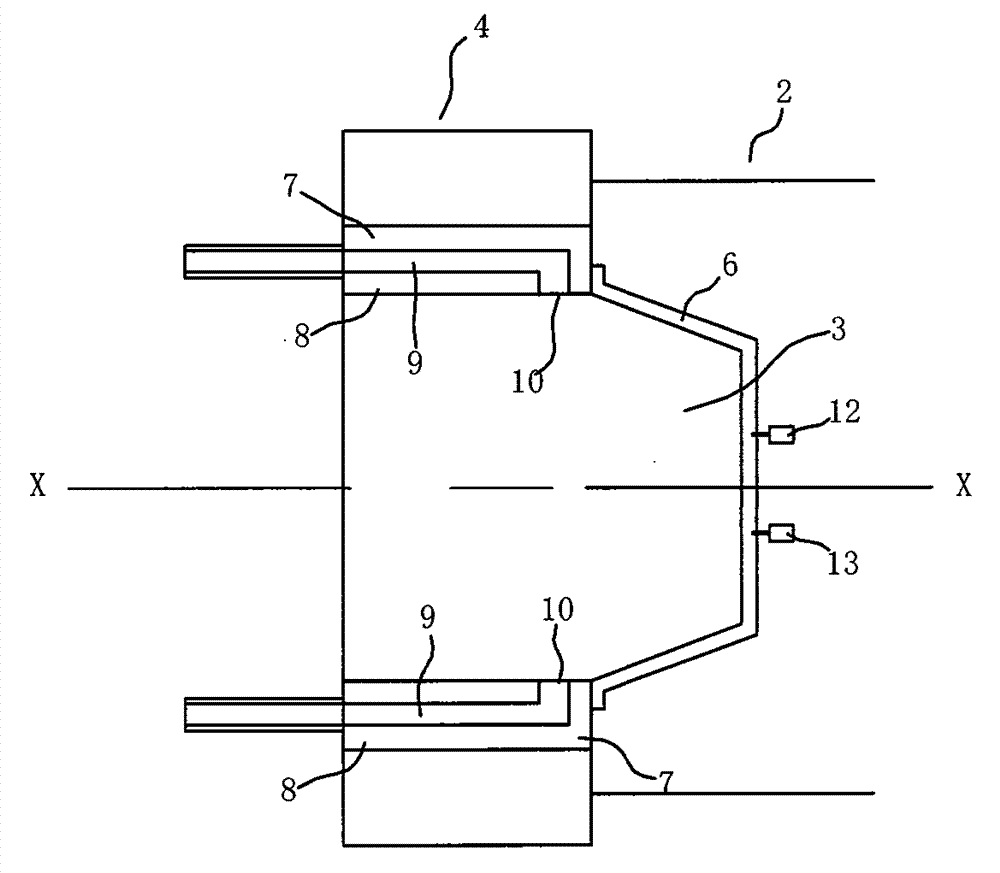

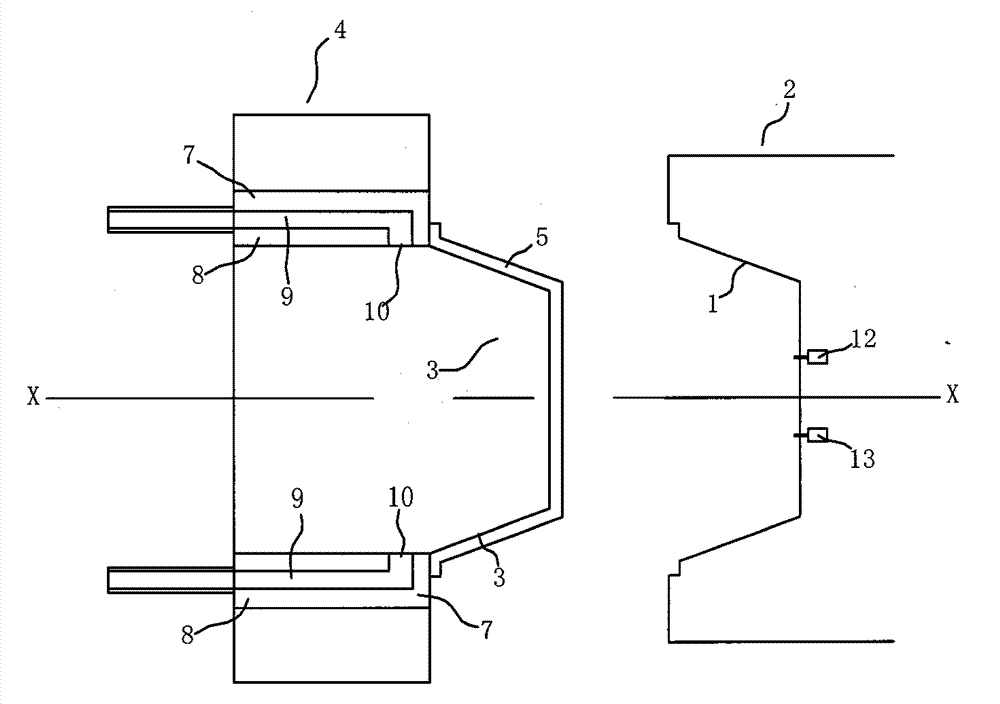

[0029] A kind of injection mold of container type plastic part 5, such as Figure 1 to Figure 8 As shown, it includes a fixed mold 2 containing a cavity 1 and a movable mold 4 containing a core 3. The core 3 is in a convex shape corresponding to the inner surface of the container plastic part 5 to be injected, and the cavity 1 is in a shape corresponding to the inner surface of the plastic part 5 to be injected. The outer surface of the container-type plastic part 5 is in a corresponding concave shape. After the cavity 1 and the core 2 meet, their respective axes X coincide to form the molding space 6 of the container-type plastic part 5. The movable mold 4 moves along the outer surface of the core 3. At least two push rods 7 are set at the circumferential position where the diameter is located, and the push rods 7 can move along the push rod slide hole 8 arranged on the movable mold 4, and the runner holes 9 for compressed air introduction are arranged in the push rod 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com