Preparation method of self-clinching-bottom paper box

A carton and self-buckling technology, which is used in box making operations, rigid/semi-rigid container manufacturing, papermaking, etc., can solve the problems of poor molding effect, unfastened locks, and easy-to-open locks, achieving easy molding. , the bottom of the buckle is firm, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

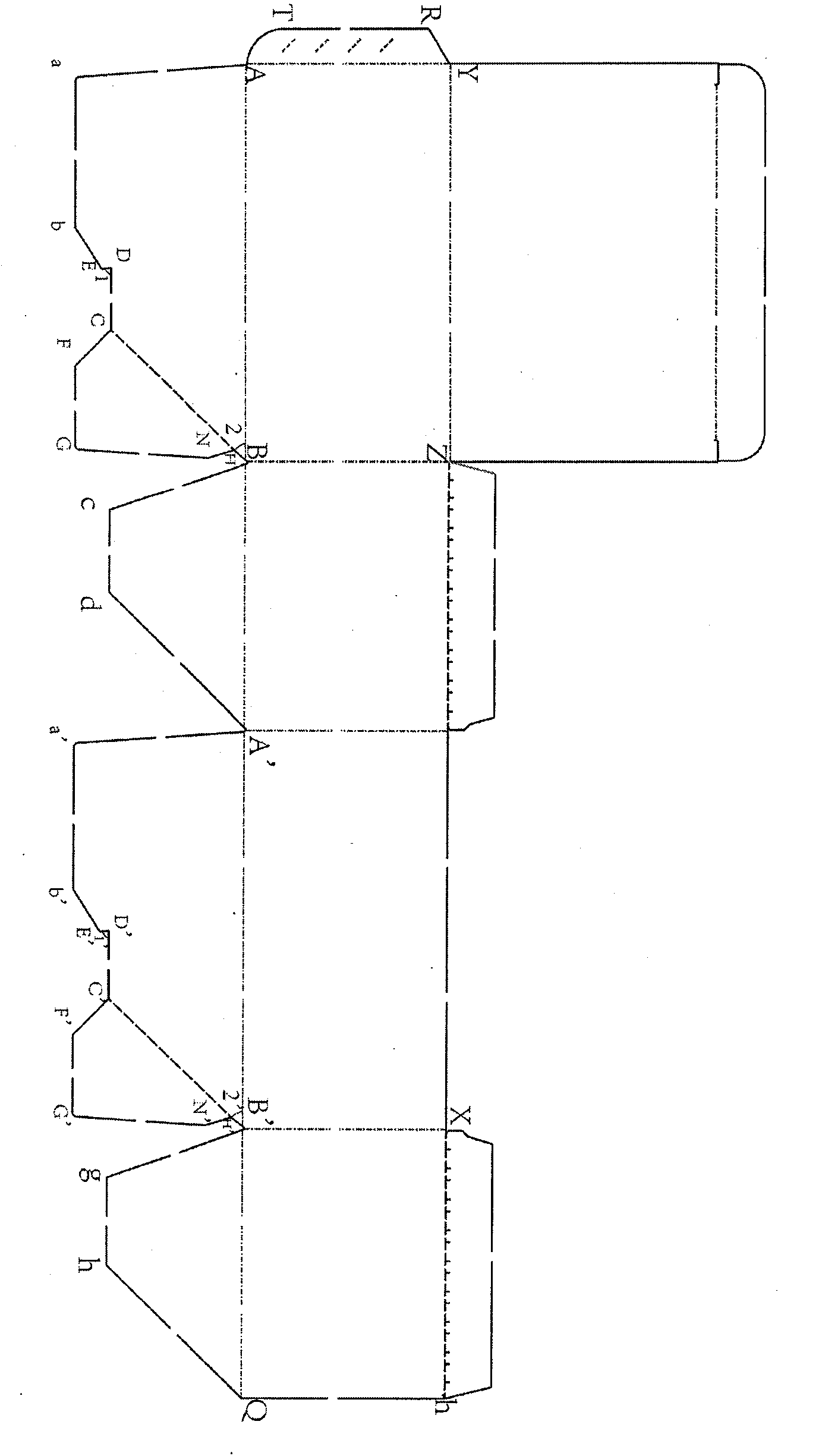

[0028] see figure 1 Described, a kind of preparation method of self-button bottom carton comprises the following steps:

[0029] 1) Select a laminate with a thickness of 20mm, a length of 2000mm and a width of 1200mm for use;

[0030] 2) Use a slotting machine to saw the selected laminate into a board that is 100 mm longer and 100 mm wider than the product to be produced for use;

[0031] 3) In the center position of the prepared laminate, according to the process requirements and size drawing, it is particularly important that the angle between line AB, line BC and line A'B' and line B'C' must be ∠2=∠2'=46 °; the angle between lines DC and DE and lines D'C' and D'E' mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com