Inner-aeration hollow fiber film carrier module and its application method

A fiber membrane and carrier technology, applied in the field of biofilm water treatment technology and equipment, can solve problems such as abnormal odor, large filter bed volume, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

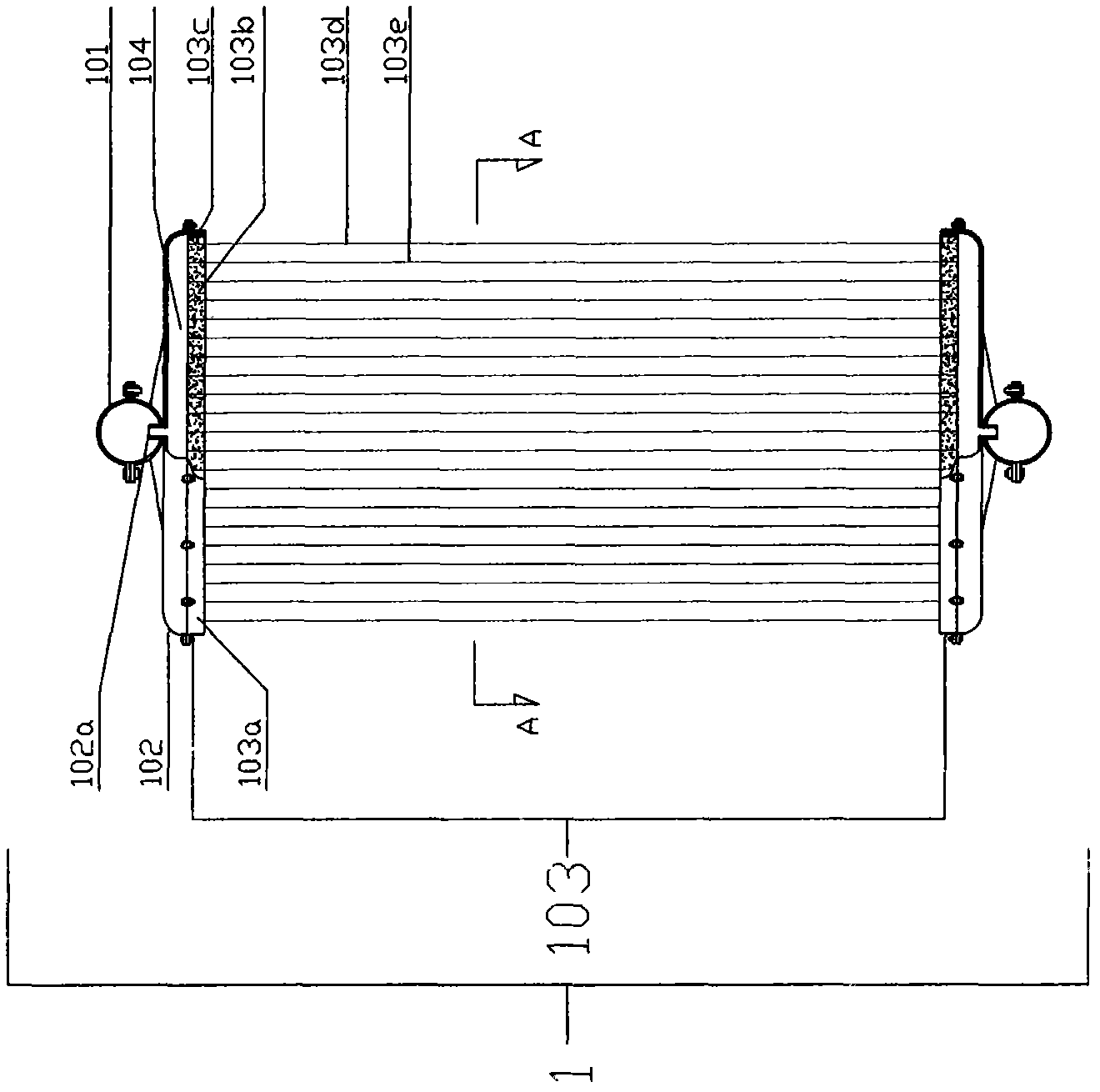

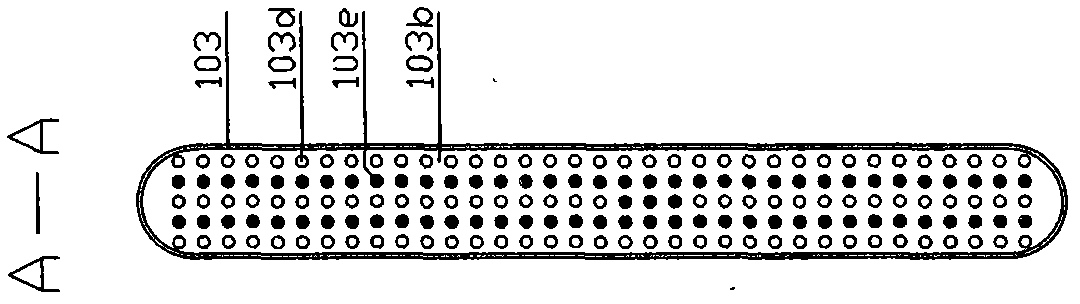

[0020] This example describes an internal aeration hollow fiber biofilm carrier module and its application method. The internal aeration hollow fiber biofilm carrier module described in this embodiment includes a carrier element (1), an upper air distribution pipe (2), a lower air collecting pipe (3), a support pipe (4), and an air inlet (5) , purge port (6), drug washing connection port (7) and liquid medicine return port (8). The carrier element (1) is assembled from an arc-shaped fixing card (101), an air distribution cavity part (102), and a fiber module (103). The structure of the air distribution cavity part (102) is a T-shaped bracket, the bottom of which is a U-shaped open cavity, and there are several fixing bolt platforms on the outer edge of the bottom; its upper part is an arc-shaped fixing bracket, And the circular nozzle (102a) passes through the center of the upper arc-shaped fixing bracket and communicates with the U-shaped opening, and when assembled with the f...

Embodiment 2

[0024] This example describes another embodiment of the internal aeration hollow fiber biofilm carrier module and its application method. It includes a carrier element (1), an upper air distribution pipe (2), a lower air collecting pipe (3), a support pipe (4), an air inlet (5), a purge port (6), a chemical washing connection port (7) and Liquid medicine return port (8). The carrier element (1) is assembled from an arc-shaped fixing card (101), an air distribution cavity part (102), and a fiber module (103). Its air distribution chamber part (102) is constructed as a T-shaped Tito, with a U-shaped open cavity at its bottom ring-shaped part, and several fixing bolt platforms on the edge of the bottom ring-shaped part; its upper part is arc-shaped The card holder is fixed, and the circular nozzle (102a) passes through the center of the upper arc-shaped fixed card holder to communicate with the U-shaped opening. When assembled with the fiber module (103), an air distribution cav...

Embodiment 3

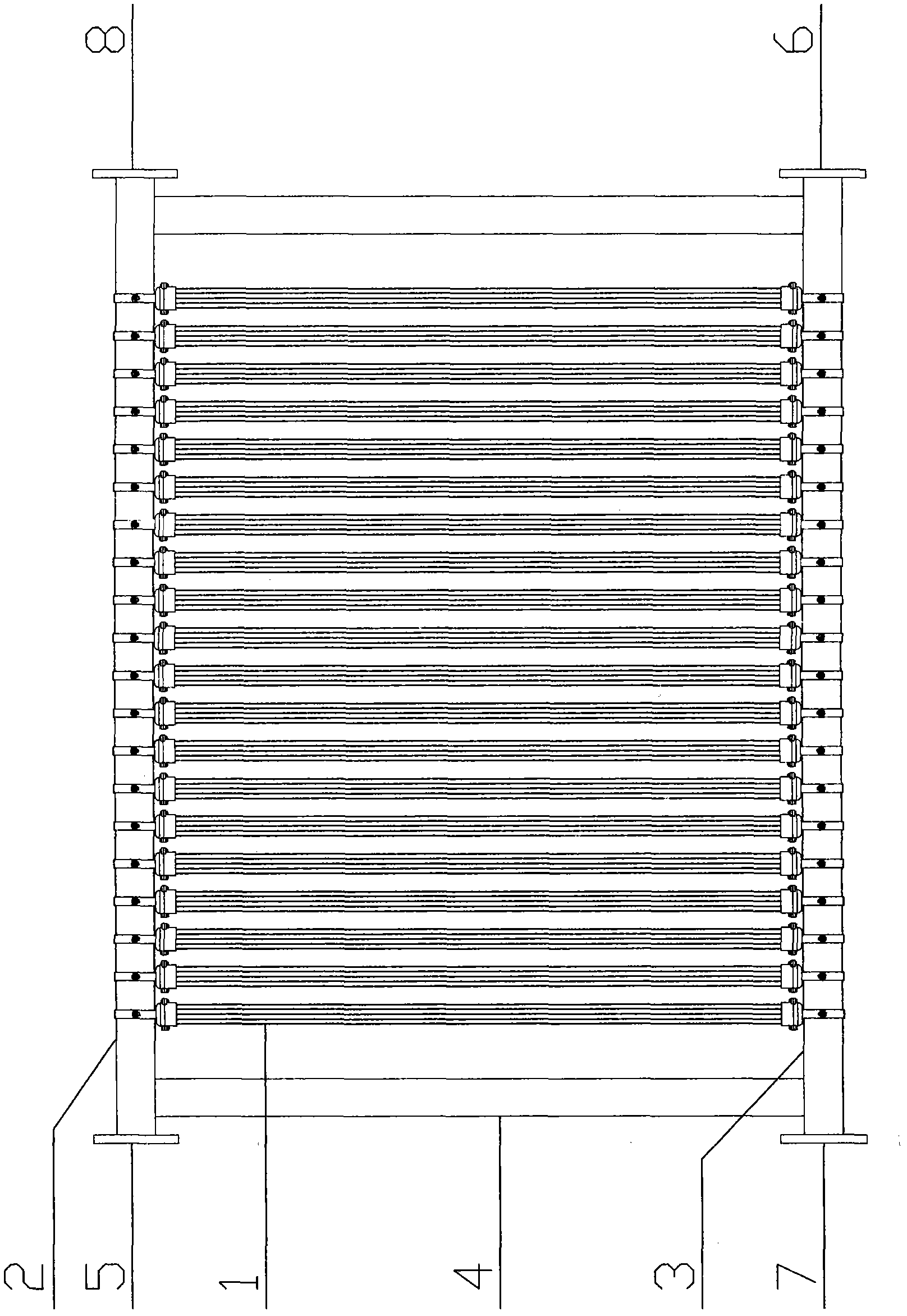

[0027]This embodiment describes an embodiment in which the internal aeration hollow fiber biofilm carrier modules are arranged in double rows to form a module unit. The realization of the technical solution is that the first step is to use two upper air distribution pipes (2) and 2 tees with the same diameter, 4 elbows and required pipe fittings to make a rectangular air distribution loop, and two on the rectangular air distribution loop. One of the tee ports is used as the air inlet (5) and the other is used as the liquid medicine return port (8); secondly, use two tees and 4 elbows of the same diameter as the two lower air collecting pipes (3) and all Pipe fittings are required, and made into a rectangular loop with the same size as the rectangular gas distribution loop. One of the two tee ports on the rectangular loop is used as the purge port (6) and the other is used as the chemical washing connection port (7); then, use The two support tubes (4) are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com