Novel beta-aminopropanoic acid synthesis technology

A kind of technology of aminopropionic acid and synthesis process, which is applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of β-alanine acid destruction, unqualified finished product quality, long production time, etc., and achieve concentration The effect of short cycle, shortened recovery cycle and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

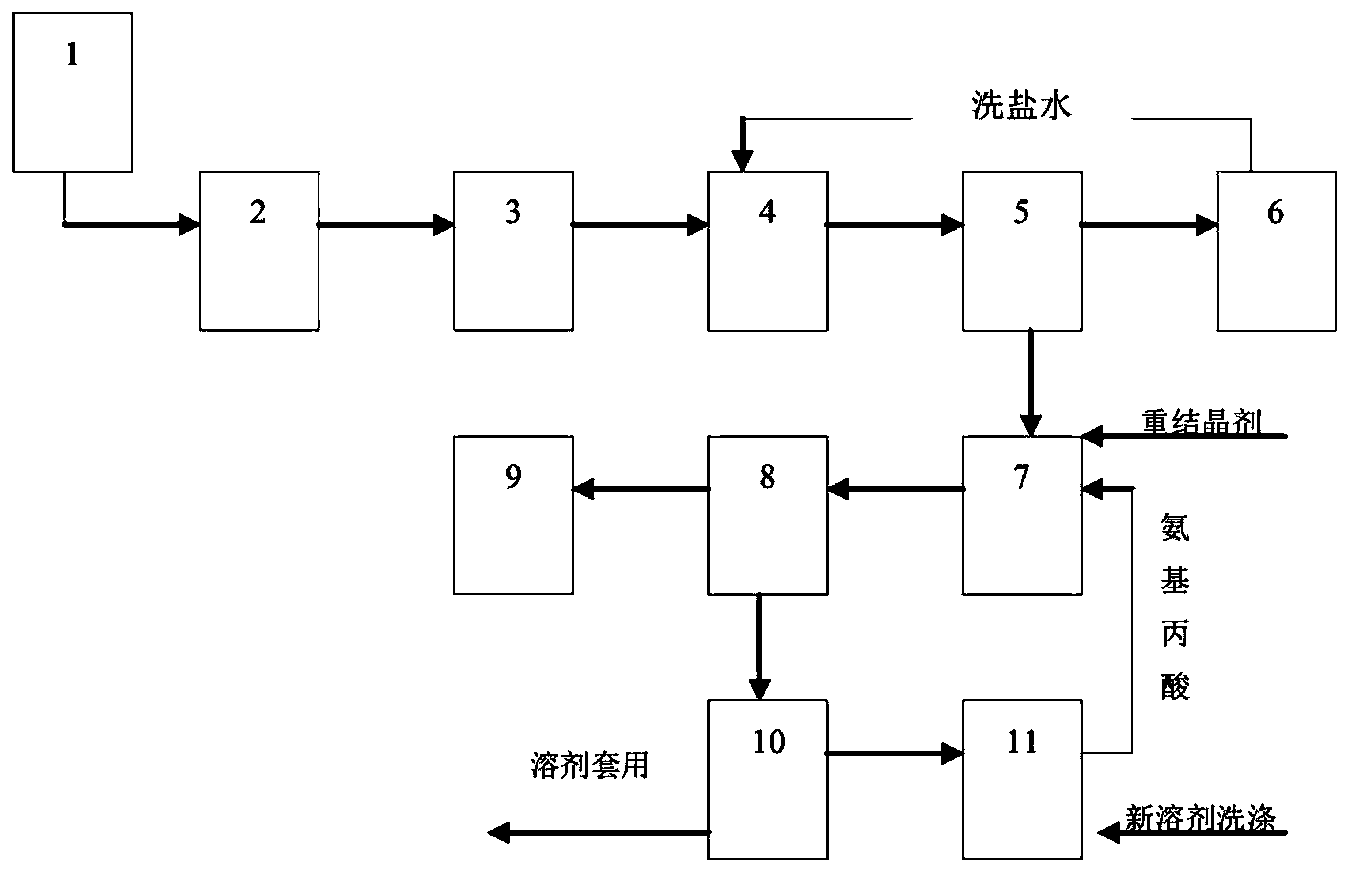

[0035] (1) Hydrolysis, temperature-controlled dropwise addition of β-aminopropionitrile in the β-aminopropionitrile metering tank 1 to the hydrolysis kettle 2 in which liquid caustic soda has been added to carry out the hydrolysis reaction;

[0036] (2) Neutralization, using hydrochloric acid to neutralize the hydrolyzed solution in the neutralization tank 3;

[0037] (3) Concentrate and concentrate in the concentration kettle 4 while maintaining a certain temperature and vacuum;

[0038] (4) Heat filtration, adding a salting-out agent and using a centrifuge 5 for direct heat filtration, and the filtrate is cooled and filtered to obtain the crude product of β-alanine;

[0039] (5) Synchronous operation, the filtrate obtained by filtering the crude product of β-alanine is returned to the concentrated and filtered cycle operation through the salt washing tank 6; at the same time, the crude product of β-alanine is dissolved to enter the next step;

[0040] (6) Recrystallization,...

Embodiment 2

[0044] hydrolysis:

[0045] 1. Add 211.2g of liquid caustic soda to the three-necked flask, raise the temperature to 80°C with a water bath, slowly open the 88g β-aminopropionitrile drop valve, and control the dropwise addition in 5-6 hours, the temperature is 80-90°C;

[0046] 2. At the end of the dropwise addition, keep warm for 30 minutes at a temperature of 90-95°C and a pressure of -0.02MPa;

[0047] 3. After the heat preservation is completed, the ammonia is driven by vacuum.

[0048] neutralize:

[0049] 1. Cool down to about 40°C and add 230g of hydrochloric acid dropwise, and the neutralization temperature is below 50°C;

[0050] 2. When adding dropwise until 10g of hydrochloric acid remains, check the pH, continue to add dropwise until the pH is 7, and retest the pH value after half an hour.

[0051] Concentration: Keep the decompression outlet water temperature at 85-100°C and the vacuum degree above -0.09MPa.

[0052] Hot Filtration: After adding salting-out ag...

Embodiment 3

[0063] hydrolysis:

[0064] 1. Add 105.6g of liquid caustic soda into the three-necked flask, raise the temperature to 80°C with a water bath, slowly open the 44g aminopropionitrile drop valve, control the dropwise addition within 2-3 hours, and the temperature is 80-90°C;

[0065] 2. At the end of the dropwise addition, keep warm for 30 minutes at a temperature of 90-95°C and a pressure of -0.02MPa;

[0066] 3. After the heat preservation is completed, the ammonia is driven by vacuum.

[0067] neutralize:

[0068] 1. Cool down to about 40°C and prepare to add 115g of hydrochloric acid dropwise, and the neutralization temperature is below 50°C;

[0069] 2. When adding dropwise until 10g of hydrochloric acid remains, check the pH, continue to add dropwise until the pH is 7, and retest the pH value after half an hour.

[0070] Concentration: Keep the decompression outlet water temperature at 85-100°C and the vacuum degree above -0.09MPa.

[0071] Hot Filtration: After adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com