Heat curing agent and preparation method thereof, frame sealing adhesive, display panel and display device

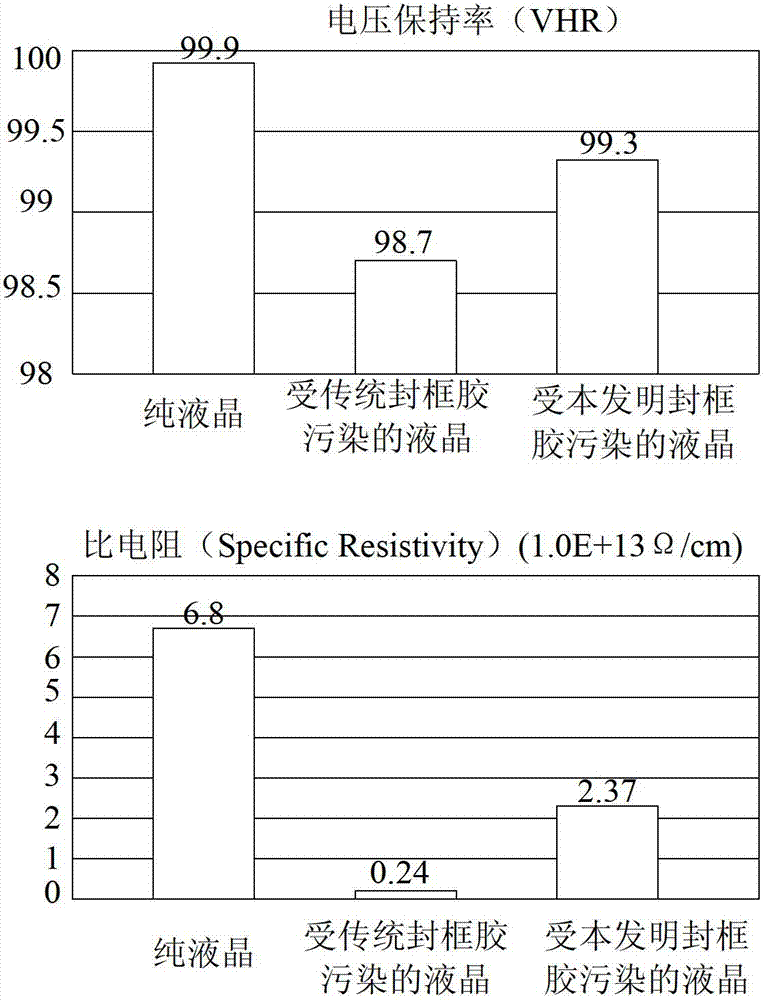

A technology of thermal curing agent and frame sealing glue, applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve problems such as pollution and reduce picture quality, and achieve the effect of reducing pollution and improving picture quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

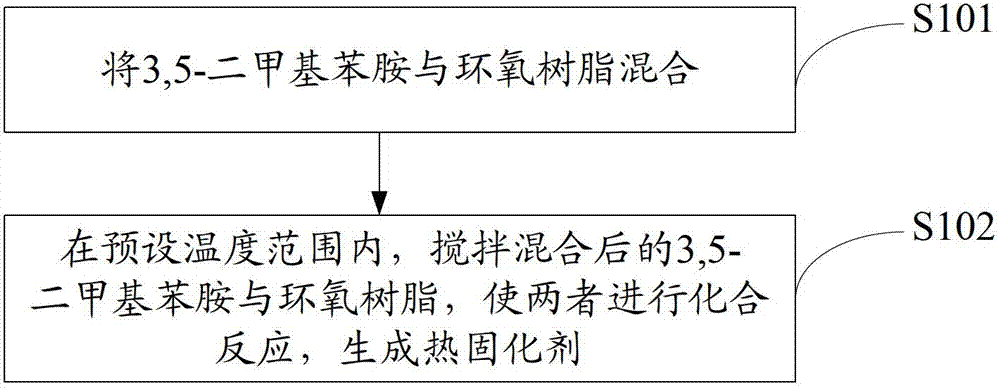

[0037] The embodiment of the present invention provides a kind of preparation method of thermosetting agent, such as figure 1 Shown, this preparation method comprises:

[0038] S101. Mixing 3,5-dimethylaniline and epoxy resin.

[0039] The mixing ratio of 3,5-dimethylaniline and epoxy resin can be determined according to actual needs in industrial production, and is not limited in the embodiments of the present invention. However, according to the reaction principle of the combination reaction of the two, in the embodiment of the present invention, it is preferred to mix 3,5-dimethylaniline and epoxy resin with a molar ratio of 2:1, so that the two react completely, So that no raw materials are wasted.

[0040] Wherein, the above-mentioned epoxy resin may be a bisphenol A epoxy resin with an epoxy value of 0.51.

[0041] S102. Stir the mixed 3,5-dimethylaniline and epoxy resin within the preset temperature range to make the two undergo a chemical reaction to generate a ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com