Molten steel vacuum refining top gun

A vacuum refining and top gun technology, applied in the direction of lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of shortened service life, burnout of nozzles, and reduced service life, so as to prolong service life, increase flow speed, and improve labor efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

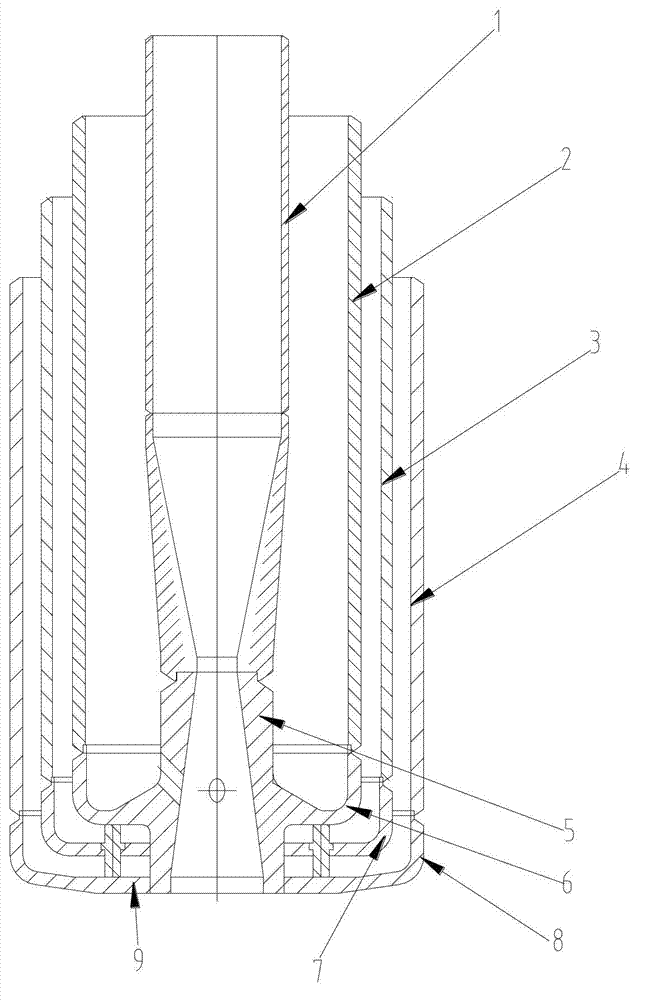

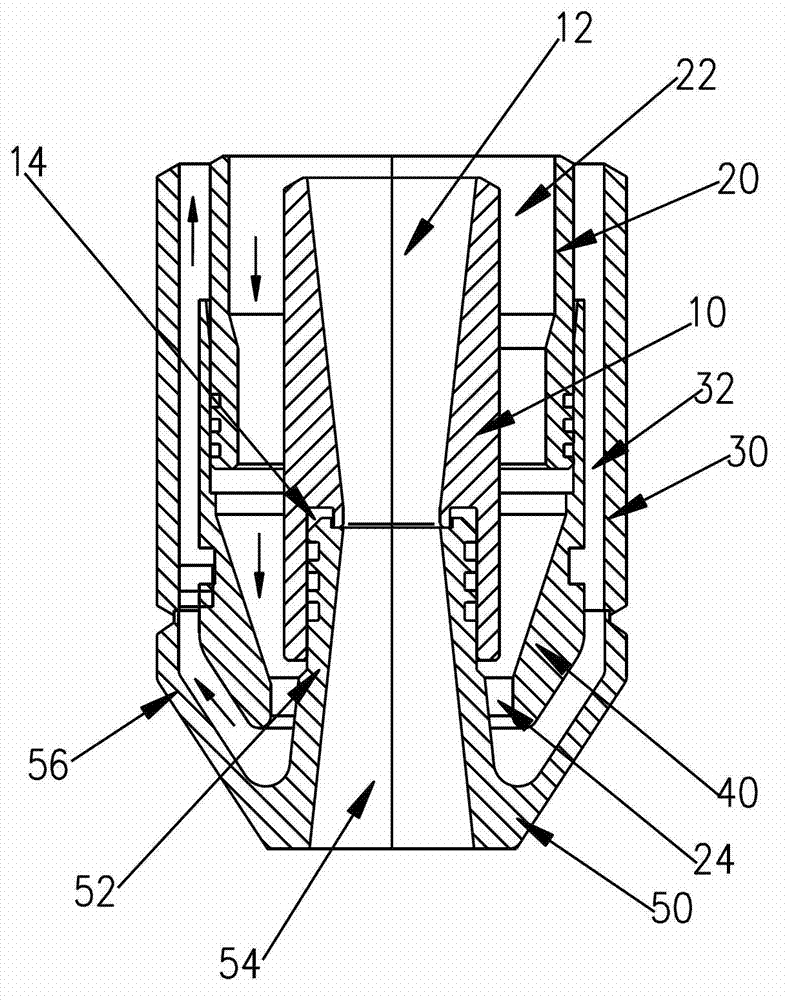

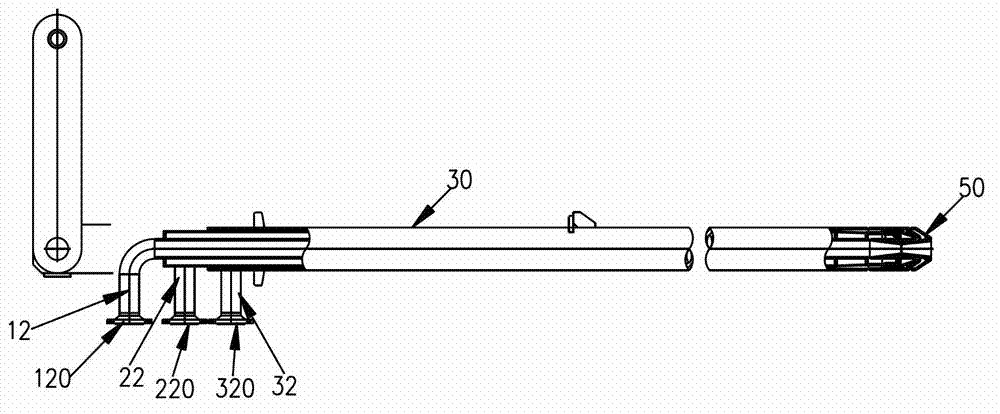

[0015] Example: such as Figure 2-3 As shown, it is a specific embodiment of a molten steel vacuum refining top gun of the present invention, which includes a center pipe 10, an inner pipe 20 located outside the center pipe 10 and used for inputting cooling water, and an inner pipe 20 located outside the inner pipe 20 and used The outer pipe 30 for outputting cooling water, the intermediate pipe 40 mated with the inner pipe 20 , and the nozzle 50 mated with both the central pipe 10 and the outer pipe 30 . Wherein the central pipe 10 has an oxygen injection channel 12 connected to the oxygen injection port 120, an input passage 22 for cooling water and connected to the water inlet 220 is formed between the inner pipe 20 and the central pipe 10, and between the outer pipe 30 and the inner pipe 20 An output channel 32 for cooling water is formed and connected to the water outlet 320 . There is a threaded connection between the inner pipe 20 and the middle pipe 40 . The bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com