A kind of production process of direct plating type tipping paper for cigarette

A production process and tipping paper technology, used in papermaking, paper coatings, layered products, etc., to achieve the effects of good decorative effect, simple production process, and green product index performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention are provided below for those skilled in the art to better understand the technical idea of the present invention, but the present invention is not limited to the embodiments.

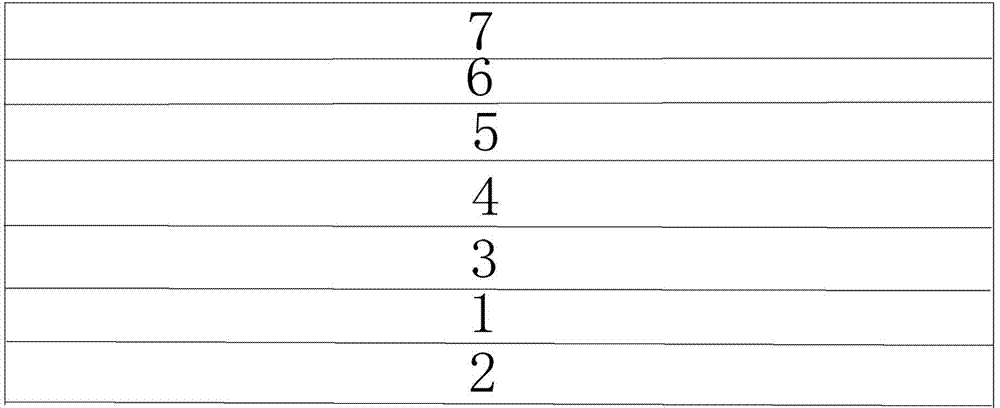

[0029] at 34g / m 2 Zhejiang Minfeng ordinary tipping paper base paper 1 is coated with a printing (or coating) equipment at a speed of 110±10m / min, an oven temperature of 110±10°C, and a coating pressure of 2.5±1KG. Coating to form back coating 2, so that the back of the paper penetrates to the back of the paper when coating the direct plating glue on the front of the paper to affect the effect of vacuum aluminum plating and is conducive to the rolling of the finished direct plating type tipping paper on the cigarette machine; 34g / m after coating 2 Zhejiang Minfeng ordinary tipping paper base paper surface is coated with a layer of Hunan Eagle water-based coating at a speed of 110±10m / min, an oven temperature of 110±10°C, and a coating pressure of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com