Lateral bunker bay structure of large-scale thermal power plant

A technology for thermal power plants and side coal bunkers, applied in industrial buildings, etc., can solve the problems of reducing beam section and self-weight, increasing structural span, and inconvenient equipment maintenance, achieving the effect of reducing span, reducing transverse span, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation modes of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

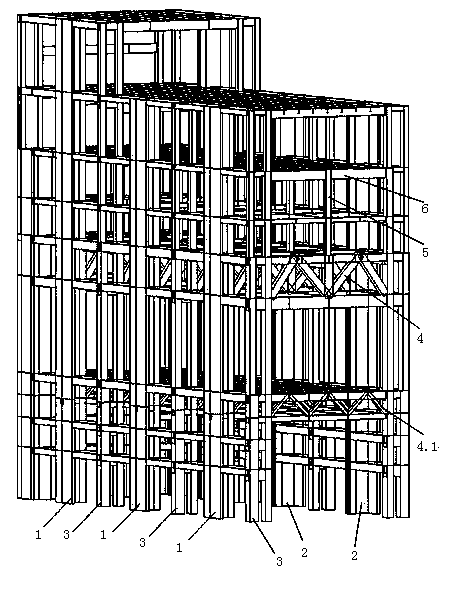

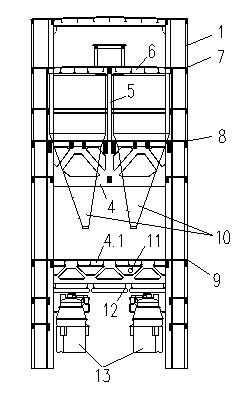

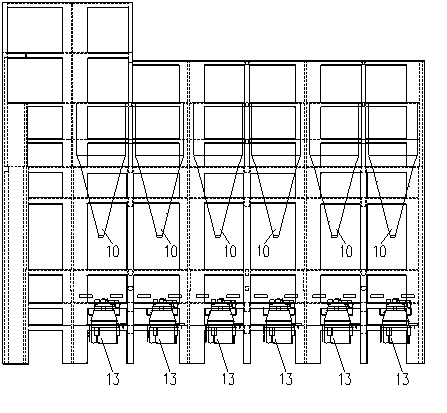

[0025] As shown in the figure, a large thermal power plant side coal bunker structure includes a frame beam 6, and longitudinal anti-seismic walls 1, transverse anti-seismic walls 2 and lattice frame columns 3 scattered around the frame beam 6, respectively. Frame beam 6, longitudinal seismic wall 1, transverse seismic wall 2, and lattice frame column 3 are all rigidly connected to form a complete lateral force-resistant structural system. , the lower chord section is far smaller than the wall and column, so the design idea of "strong column and weak beam" in which the beam joints fail before the column can be fully realized through the adjustment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com