A kind of railway prefabricated T-beam concrete pouring protective shed

A protective shed and concrete technology, which is applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of poor site practicability, many cooperating staff, complicated operation, etc., and achieve simple structure, convenient construction, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

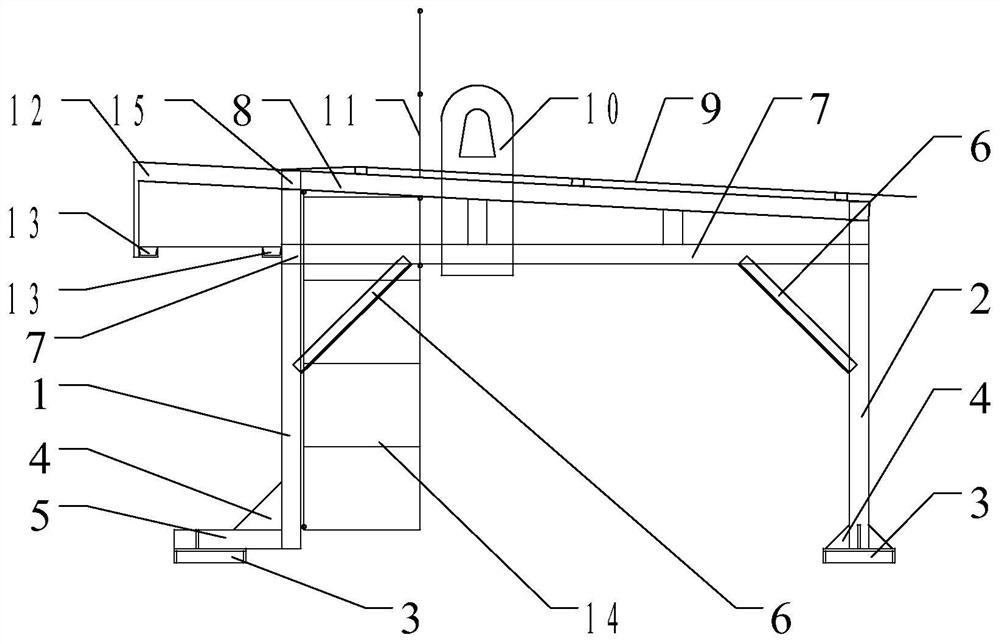

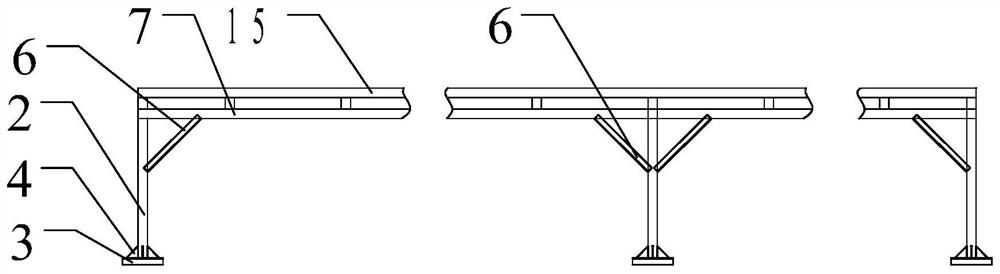

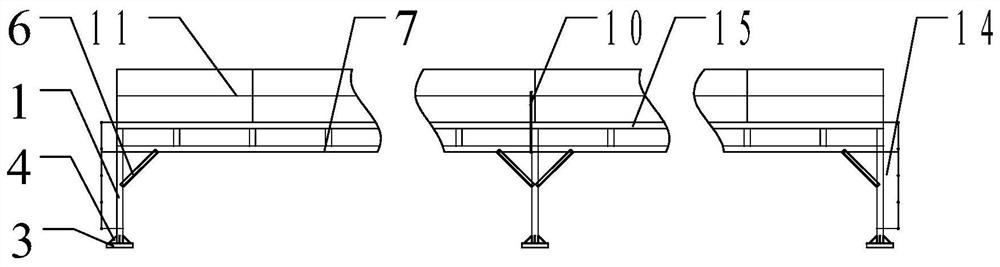

[0028] figure 1 It is a schematic diagram of the cross-sectional structure of the protective shed embodiment of a kind of railway prefabricated T-beam concrete pouring protective shed of the present invention, figure 2 It is a schematic diagram of the longitudinal section structure of the protective shed of a kind of railway prefabricated T-beam concrete pouring protective shed embodiment of the present invention, image 3 It is a schematic structural diagram of the longitudinal section of the protective shed near the end of the guide rail in an embodiment of a railway prefabricated T-beam concrete pouring protective shed acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com