Reverse-circulation slag-removal reamer bit

A technology of reaming drill bit and reverse circulation, which is applied to drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of a large amount of bentonite and high cost, and achieve the effect of cleaning slag, protecting the environment and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

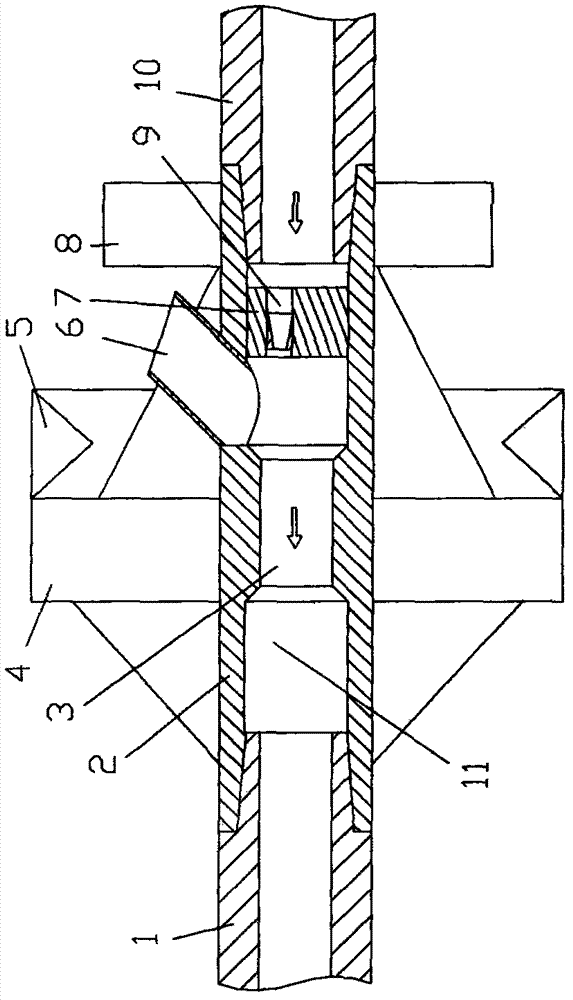

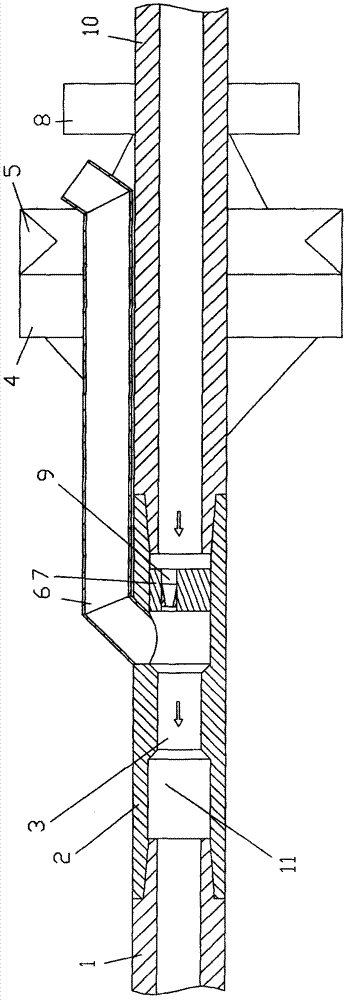

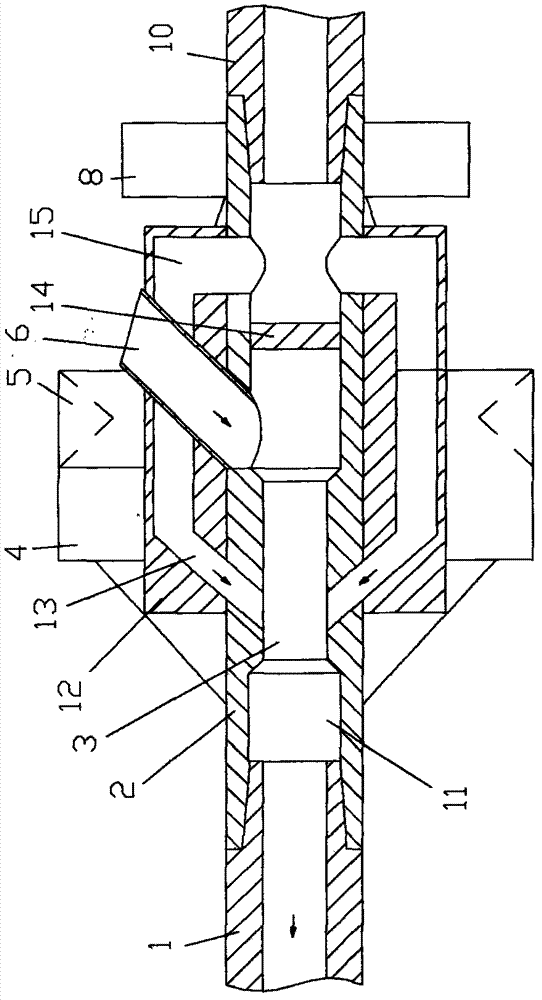

[0012] As shown in the drawings, the present invention includes a reaming device and a jet slag suction device. The reaming device includes a drill body 4, a cutting device 5 and a guide device 8. The cutting device 5 and the guide device 8 are fixed on the drill body 4; The jet slag suction device has a jet tube 2, the right end of the jet tube 2 is fixed with the inner nozzle 7, the left end of the jet tube 2 has a throat cavity 3 and a diffusion cavity 11, and the middle part of the jet tube 2 is fixed with a slag suction tube 6 and a slag suction tube 6 One end communicates with the jet pipe 2, and the other end is close to the cutting device 5; the left and right ends of the jet pipe 2 are respectively sealed and fixed to the slag conveying pipe or the rear drill pipe 1 and the front drill pipe 10.

[0013] The outer fixed annular nozzle 12 of described jet pipe 2 has oblique nozzle hole 13 and guide pipe 15 in the annular nozzle 12, and oblique nozzle hole 13 and guide pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com