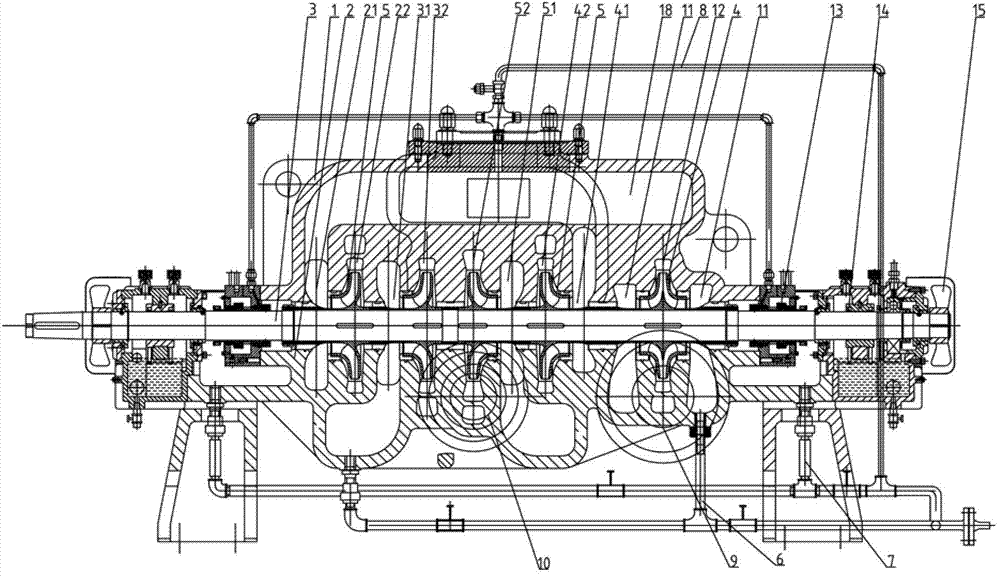

Double-suction multistage horizontal type horizontal split pump

A horizontal pump shaft technology, which is applied in the field of double-suction multi-stage horizontal split pumps, can solve problems such as inconvenient installation and replacement, unfavorable pump stability, and unavoidable leakage, so as to reduce PV value and shorten maintenance cycle , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

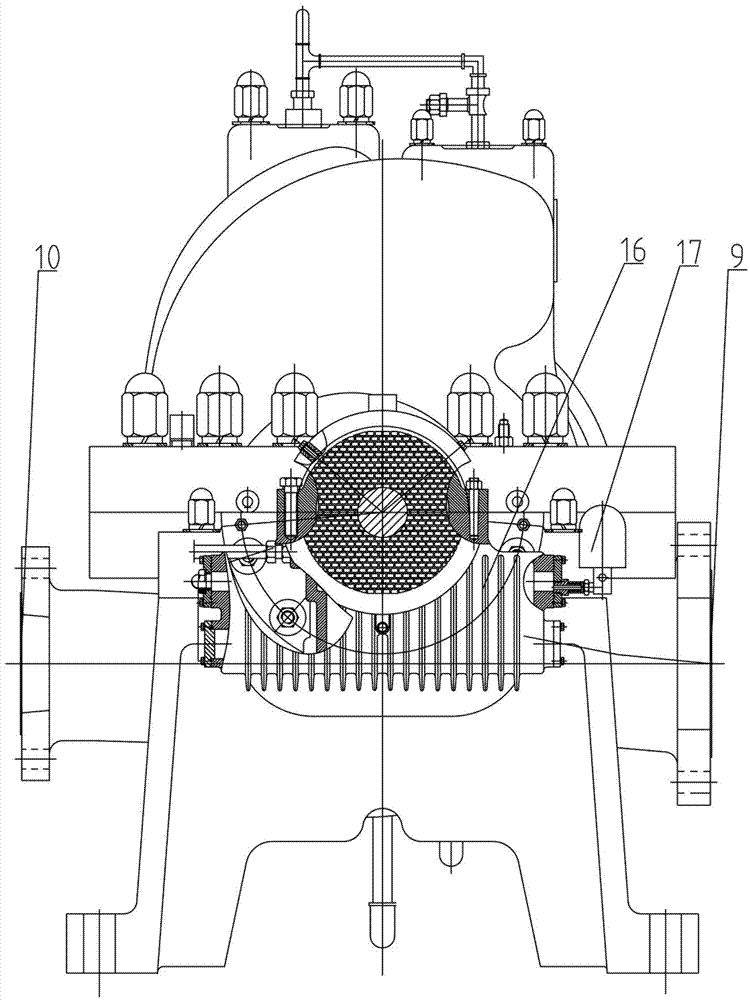

[0018] Embodiment 1, as shown in the figure, this double-suction multi-stage horizontal split pump mainly includes a pump cover 1, a pump base 2 and a pump shaft 3, and the pump cover 1 and the pump base 2 are combined up and down to form a pump casing pressure water chamber , the pump casing pressurized water chamber is a double volute double flow channel structure, the first stage impeller 4 and more than one pair of back-to-back secondary impellers 5 are installed on the pump shaft 3 from right to left, and the secondary impellers 5 are installed back to back. The pressure of the stage impellers is superimposed and superimposed to the outlet through the flow channels in series. Under the same output pressure, fewer impellers are needed and the volute is shorter. The primary impeller 4 is a double-suction impeller, and the secondary impeller 5 is a single-suction impeller. The primary impeller 4 communicates with the primary water absorption chamber 11 and the primary pressu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap