Method for simultaneously measuring temperature and stress of fiber bragg gratings (obtained by corrosion) with different diameters

A fiber grating and fiber grating demodulation technology, which is applied in the measurement, thermometer, measuring device and other directions by measuring the changing force of the optical properties of the material when it is stressed, and can solve the problem of high temperature resistance, high fiber loss, demodulation scheme Complexity and other problems, to achieve the effect of low cost and overcoming cross-sensitive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

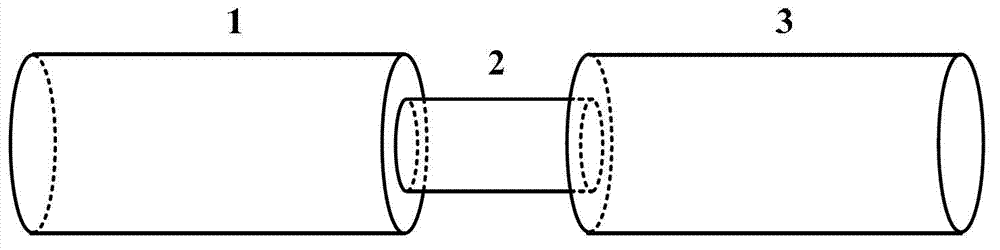

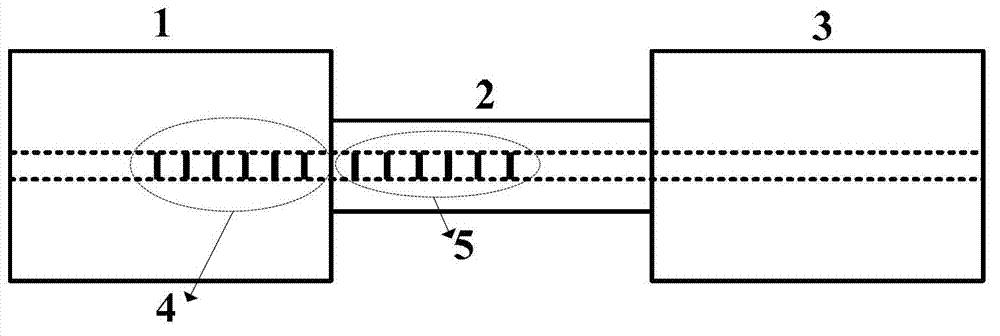

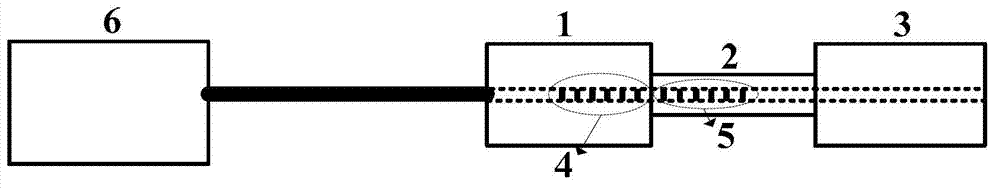

[0035] see image 3 , the device of this embodiment includes fiber gratings of different diameters obtained by etching methods, wherein 1 and 3 are ordinary uncorroded photosensitive single-mode fibers, 2 is a photosensitive single-mode fiber with a smaller diameter after corrosion, and 4 is in The grating written on the ordinary optical fiber, 5 is the grating written on the corroded optical fiber, and 6 is the fiber grating demodulator. The purpose of using two fiber gratings with different diameters is to produce fiber gratings with different stress sensitivities. Fiber Bragg grating demodulator 6 continuously scans lasers of different wavelengths to be incident on the grating produced later. When the scanned wavelength satisfies the central wavelength of the grating, the light energy of this wavelength will be reflected to the fiber Bragg grating demodulator, and the fiber Bragg grating demodulator will The retroreflected laser wavelength is recorded in real time. In thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com