Double-motor cutting-part loading test device of roller-type coal mining machine

A loading test device and dual-motor technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as high cost and complex structure of the test device, so as to reduce test costs and improve work efficiency , The effect of shortening the test installation man-hour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

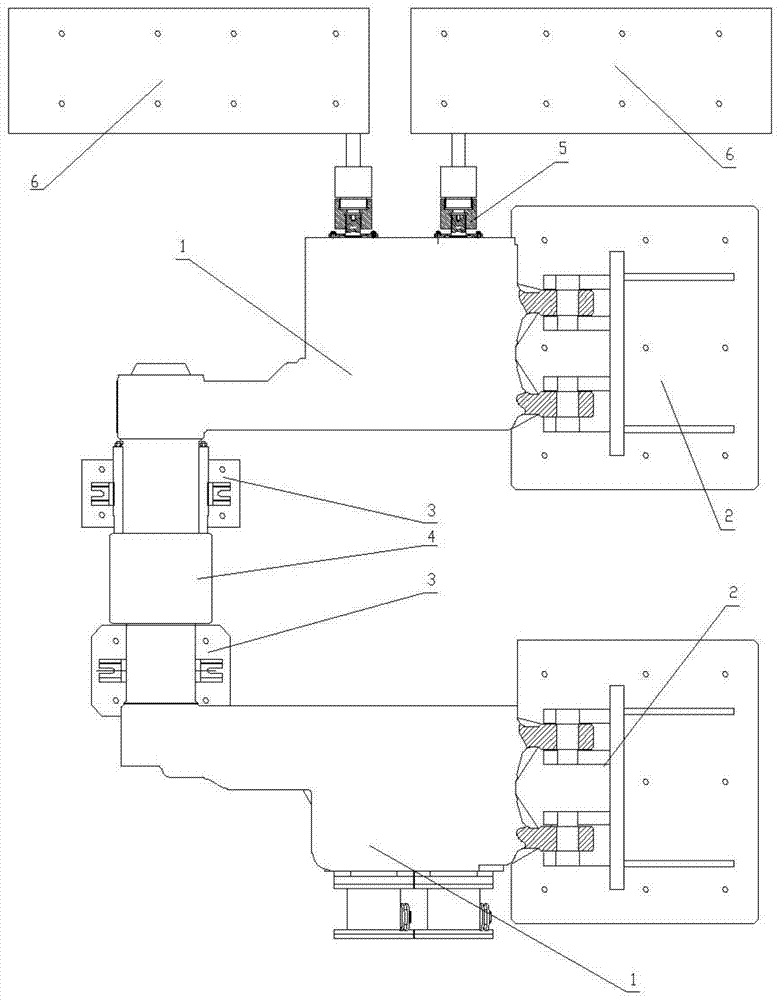

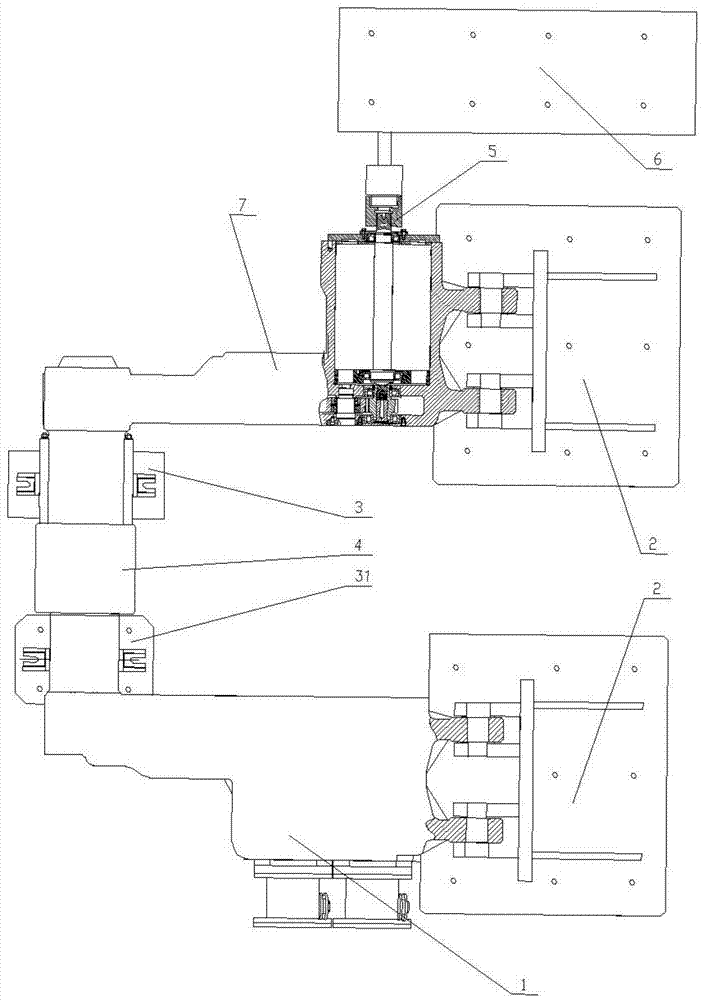

[0011] Such as figure 2 As shown, the loading test device for the dual-motor cutting part of the drum shearer consists of the tested dual-motor cutting part 1, the connecting ear support frame 2, the planetary head support frame 3, and the test connection sleeve 4. Composed of a universal coupling 5 and a torque loading device 6, one end of the tested dual-motor cutting part 1 is connected to the connecting ear support frame 2, the other end is connected to the second planetary head support frame 31, and the test connection sleeve 4 Installed between the first planetary head support frame 3 and the second planetary head support frame 31, the torque loading device 6 is connected with the universal joint 5, between the connecting ear support frame 2 and the planetary head support frame 3 A single motor cutting section 7 is installed between them.

[0012] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com