Optical connector

A technology for optical connectors and interconnections, applied in light guides, optics, instruments, etc., can solve problems such as troublesome cleaning, impossible to avoid abrasive powder, and increased connection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

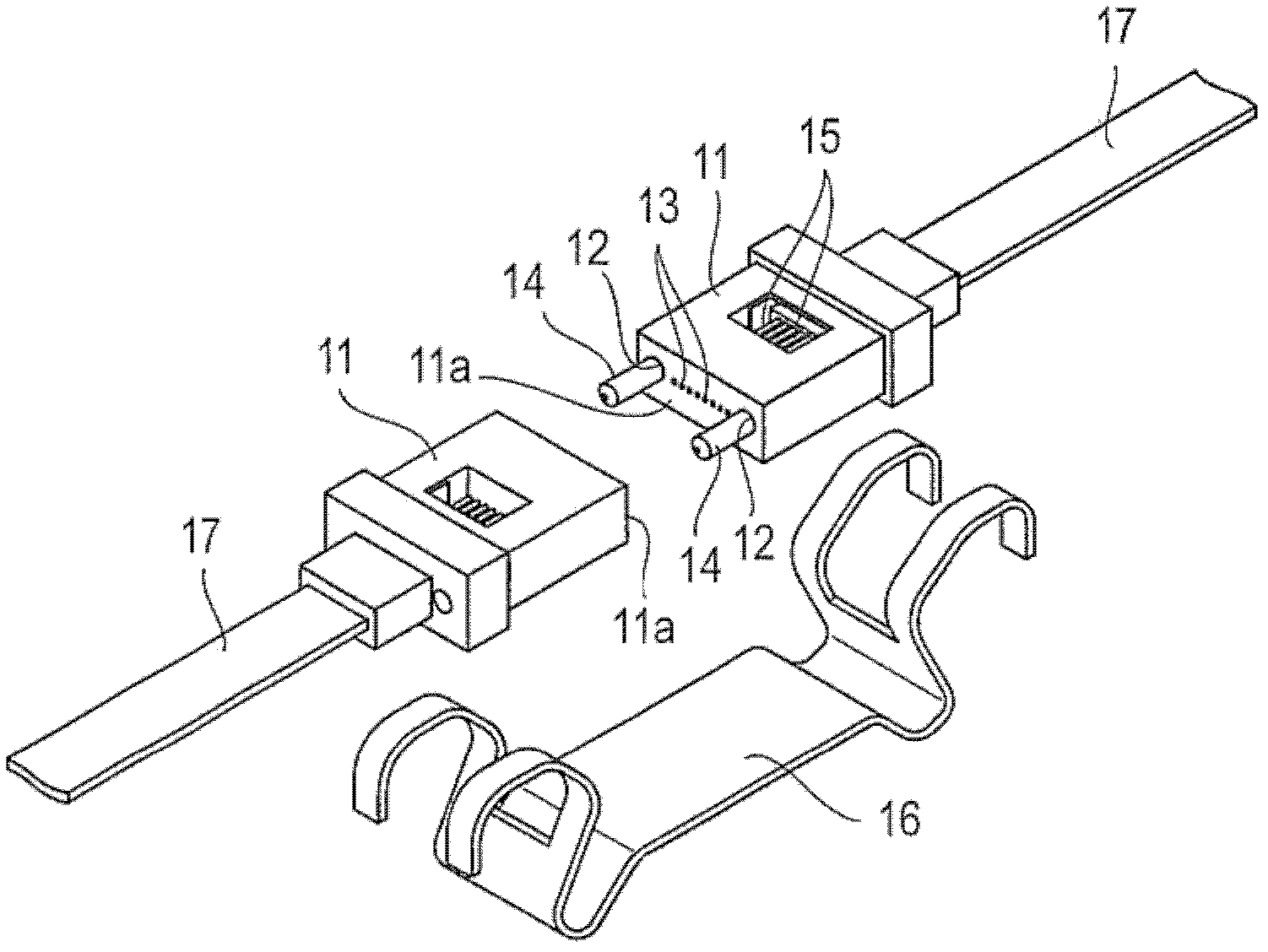

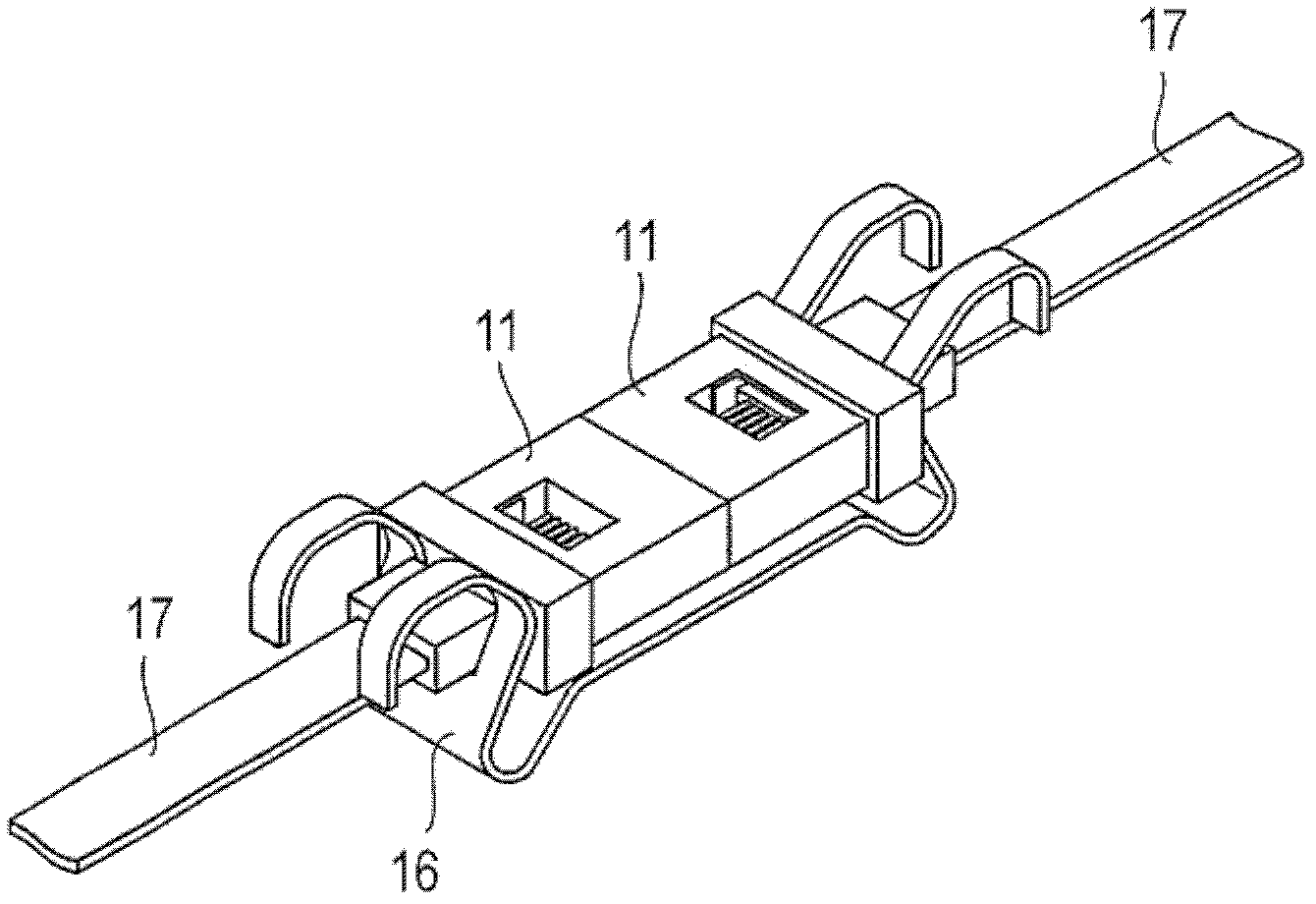

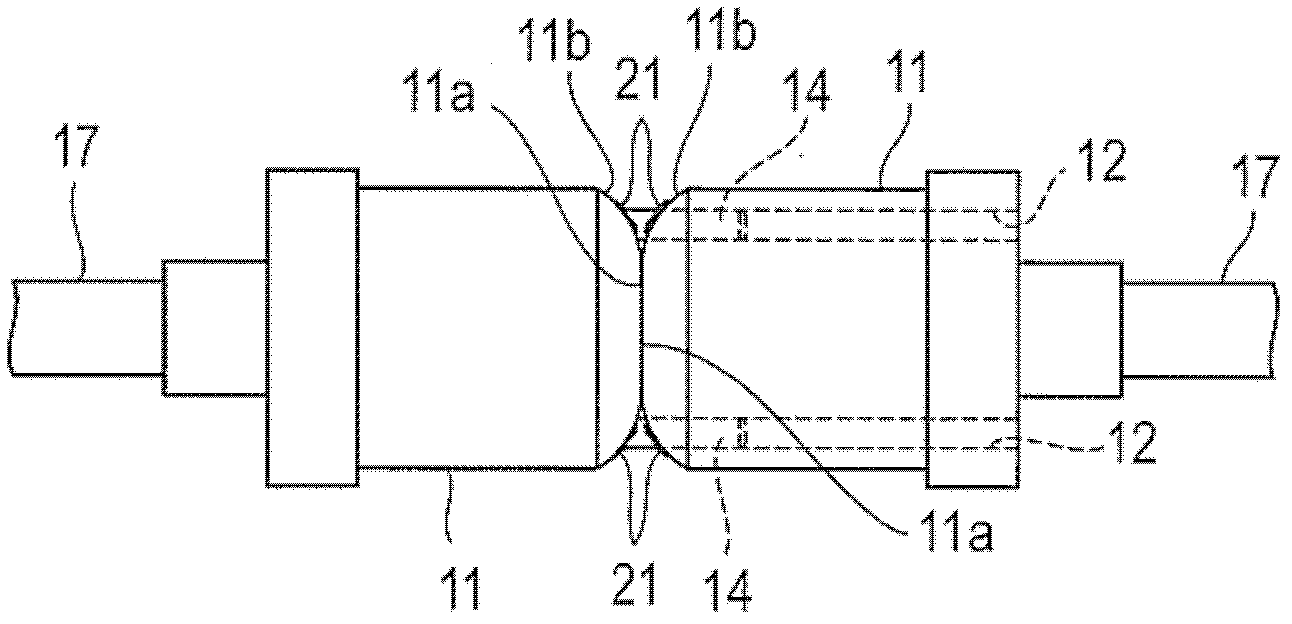

[0032] The optical connector of the present invention has, for example, the above-mentioned Figure 1A , Figure 1B In the structure of the MT-shaped optical connector shown, the end faces of the ferrules that meet each other are obliquely ground, and the gap between the guide hole that fits the guide pin and the guide pin is larger than the conventional one. The structure of the MT-shaped optical connector is: the end faces of a pair of ferrules holding a plurality of multimode optical fibers (core diameter 50 μm) are positioned by two guide pins and connected to each other, so that the optical fibers of the pair of ferrules are connected to each other .

[0033] In the following, an MT-shaped optical connector is taken as an example for description.

[0034] Figure 4 It shows that the end surfaces 11a of a pair of ferrules 11 of the MT optical connector are obliquely ground respectively, and the end surfaces 11a are positioned by guide pins 14 and connected to each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com